Test device and test method of simulating well concentration cement slurry displacement efficiency

A technology of cementing slurry and displacement efficiency, which is applied in earthwork drilling, wellbore/well components, construction, etc., which can solve the problems of nuclear radiation risk, high test cost, inability to continuously analyze the displacement process, etc., and achieve reliable hardware support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

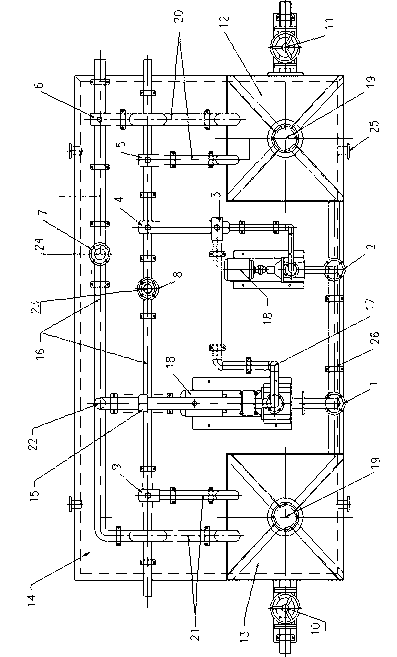

[0024] Embodiment 1, the slurry mixing and circulation displacement system is composed of a slurry mixing tank, pipelines, valves, pumps and mixers connected to form a drilling fluid slurry mixing and circulation displacement system and a displacement fluid slurry mixing and circulation displacement system, two sets The slurry mixing and circulating displacement system is connected to the annulus return nozzle and the casing inlet nozzle of the wellbore system through common and / or independent nozzles. Combine below figure 1 Explain the slurry mixing and circulation displacement system:

[0025] figure 1 Among them, 1-9 are three-way valves to control the flow of fluid; 10 and 11 are the drain valve of the displacing fluid mixing tank and the emptying (fluid) valve of the drilling fluid mixing tank respectively; 12 is the drilling fluid mixing tank (considering the circulation) pool; 13 is the displacing fluid (cement slurry) mixing slurry (considering the circulation) pool;...

Embodiment 2

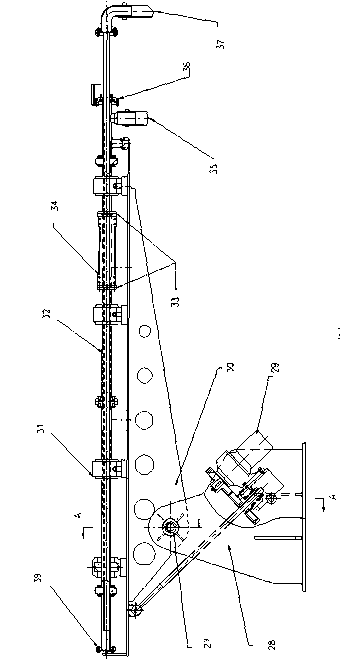

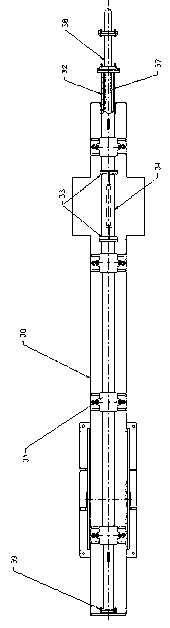

[0028] Embodiment 2, reference width figure 2 and 3 , in the figure, 27 is the inclination angle regulator, which adjusts the inclination angle of the wellbore system; 28, the wellbore support base; 29, the angle adjustment motor; 30, the support wall, supporting the wellbore system; 31, the wellbore fixed slips, used to fix the wellbore ; 32 is the wellbore; 33 is the connecting flange, connecting the wellbore and the test section; 34 is the wellbore of the test section, which can be installed with different measurement systems; 35 is the liquid return nozzle of the annular space, connected figure 1The slurry return nozzle 24 in the figure; 36 is the wellbore packer; 37 is the casing liquid inlet nozzle; 38 is the casing; 39 is the bottom hole packer.

[0029] The wellbore system includes a wellbore 32 and a casing 38 sheathed in the wellbore. The bottom end of the wellbore 32 is closed by a bottom hole packer 39 and then cooperates with the bottom end of the casing 38 to f...

Embodiment 3

[0038] Embodiment 3, the test method based on above-mentioned experimental device comprises:

[0039] For different test purposes and test methods, the device is designed to carry out simulation tests with measurement methods suitable for various displacement efficiency measurement methods:

[0040] (1). Cementation effect analysis method: When the cementation effect analysis method is used, the simulated formation core is used, and a core holder needs to be installed outside the inner cylinder. Formation cores or simulated formation cores are used to make a pilot test section 34 of a simulated wellbore, and then real drilling fluid, spacer fluid and flushing fluid and cement slurry are used. The mud cake is formed by simulating the drilling fluid flowing through the simulated formation, and then the flushing fluid or spacer fluid is used to carry out the displacement test, and then the simulated formation is taken out for the cementation test with the cement slurry, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com