Eccentric directional assembly for eccentric reaming, eccentric dosing assembly, eccentric reaming assembly, kits and methods

An eccentric and component technology, applied in the field of hole processing, can solve the problems of low workpiece positioning accuracy, no measuring mechanism, and low precision, and achieve the effects of adjustable hole diameter, convenient and simple operation, and accurate eccentric direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so as to more clearly connect the inventive principle and beneficial technical effects of the present invention.

[0094] Explanation of terms used in this article:

[0095] Horizontal and longitudinal: The horizontal in this article is not the absolute horizontal in the conventional sense, but refers to two mutually perpendicular axes, if one of the axes is called vertical, the other axis is called horizontal, and vice versa.

[0096] Top: The end away from the workpiece.

[0097] Bottom: The end close to the workpiece.

[0098] Landscape section: Corresponds to the above-mentioned horizontal portrait.

[0099] Vertical section: Perpendicular to the horizontal section.

[0100] Eccentricity: the value of eccentricity.

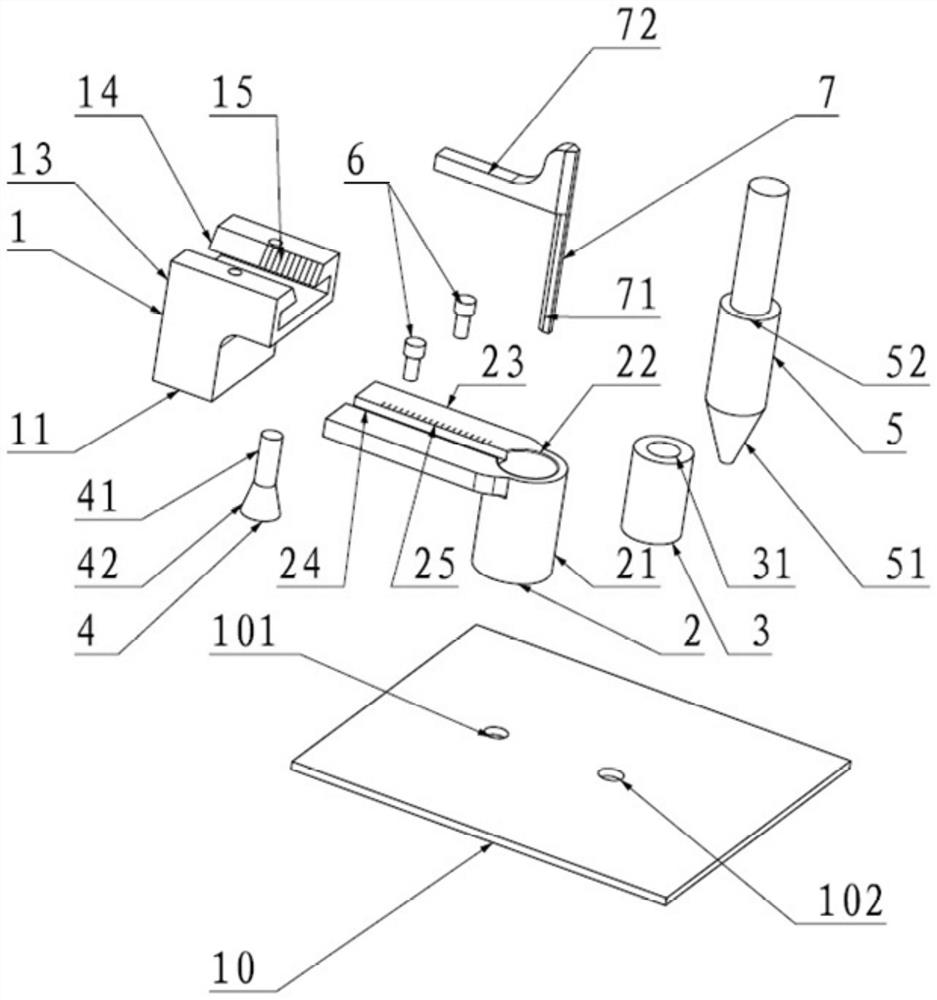

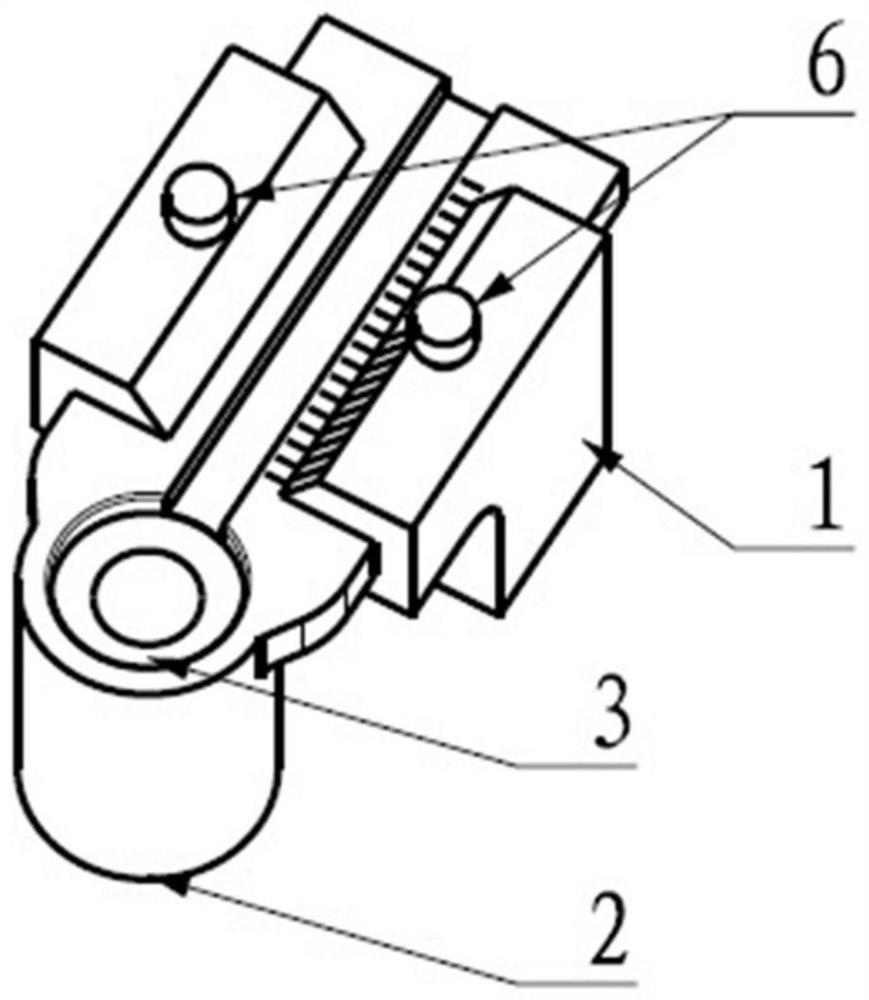

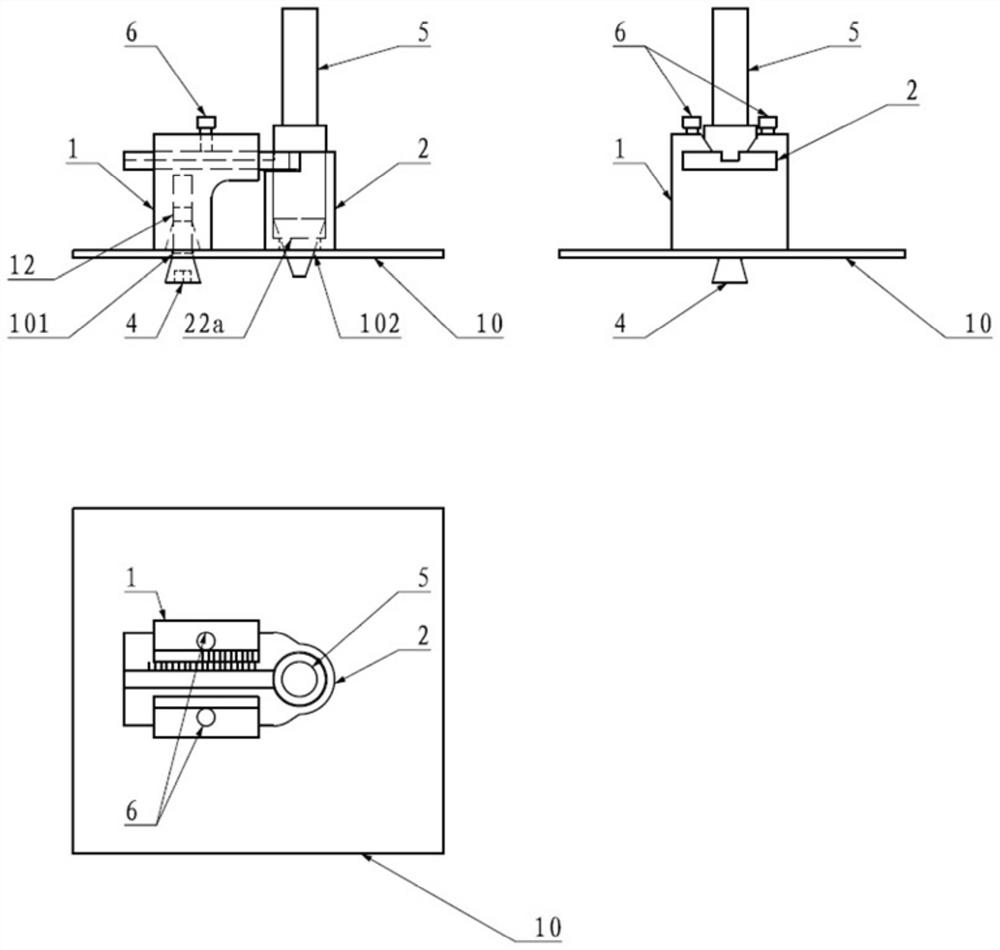

[0101] figure 1 is an exploded perspective view of a set of eccentric reaming of workpieces according to the present invention, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com