Solid spring ball and process for making same

A manufacturing method and technology of bouncy balls, which are applied in the fields of entertainment and sporting goods, can solve the problems of easy foaming, shortened use time, weakened resilience of products, etc., and achieve improved brightness and wear resistance, simple manufacturing method, and improved bonding degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

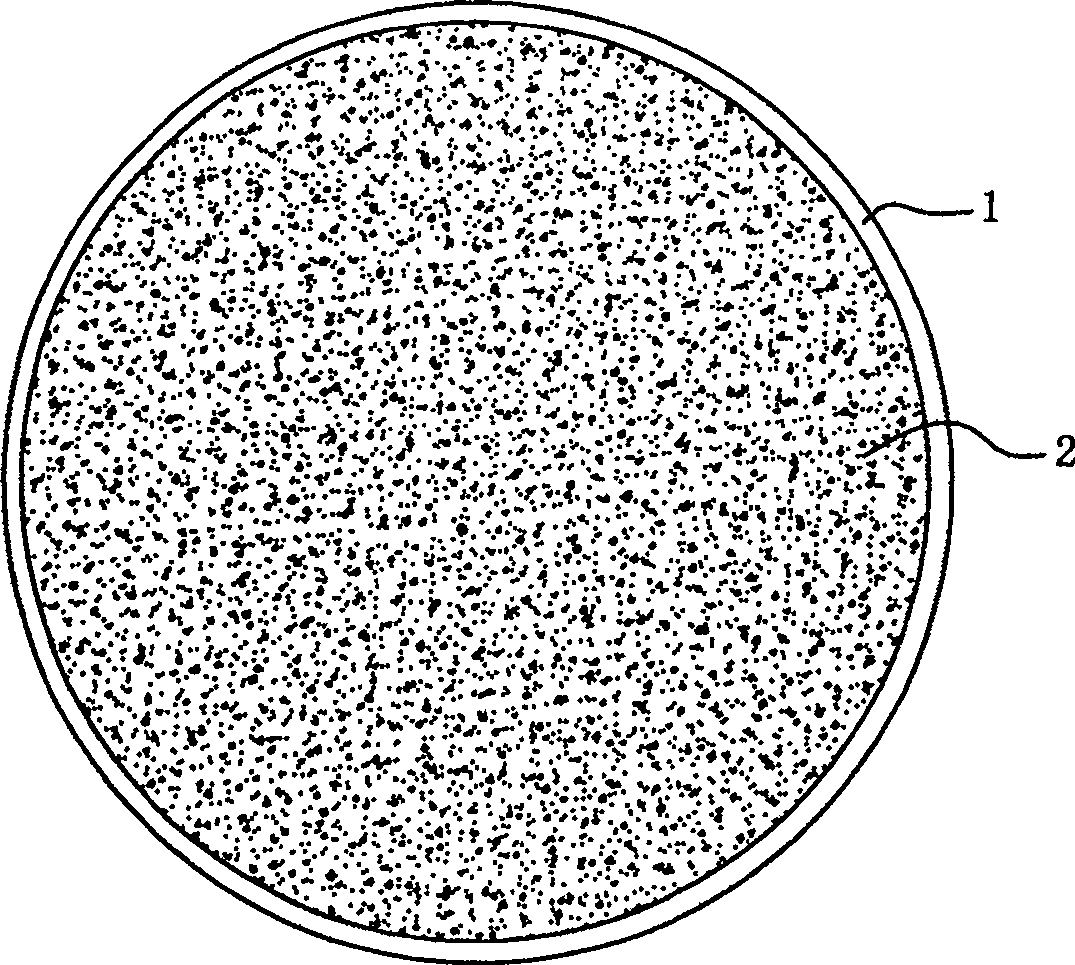

[0019] refer to figure 1 , the solid elastic ball in the present embodiment includes a built-in foamed PU material ball center 2 and a spherical latex bag 1 wrapped in the outer wall of the PU material ball center. In order to improve the brightness and wear resistance of the ball, the latex bag The outer wall is sprayed with PU bright oil and PU wear-resistant oil.

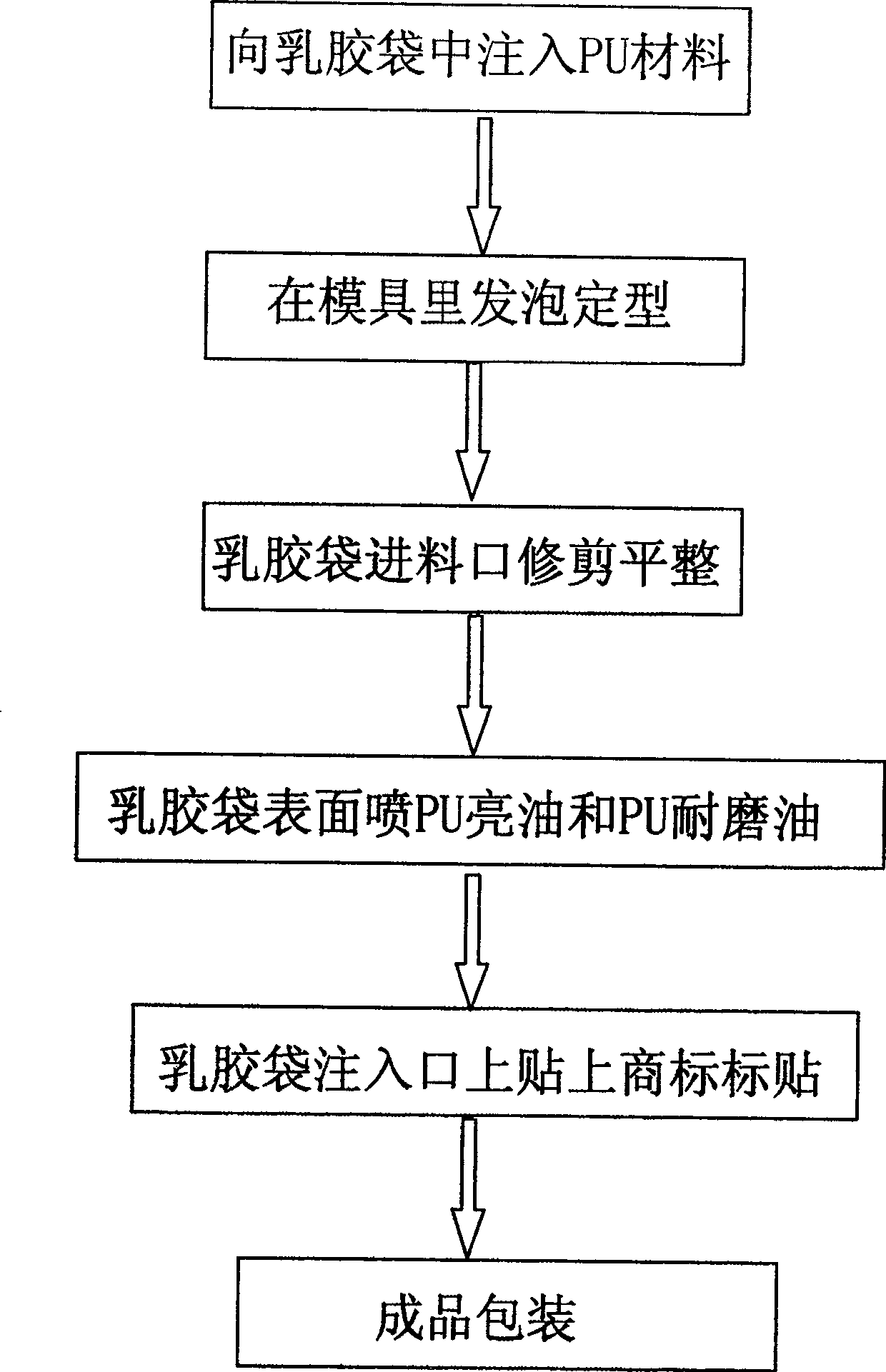

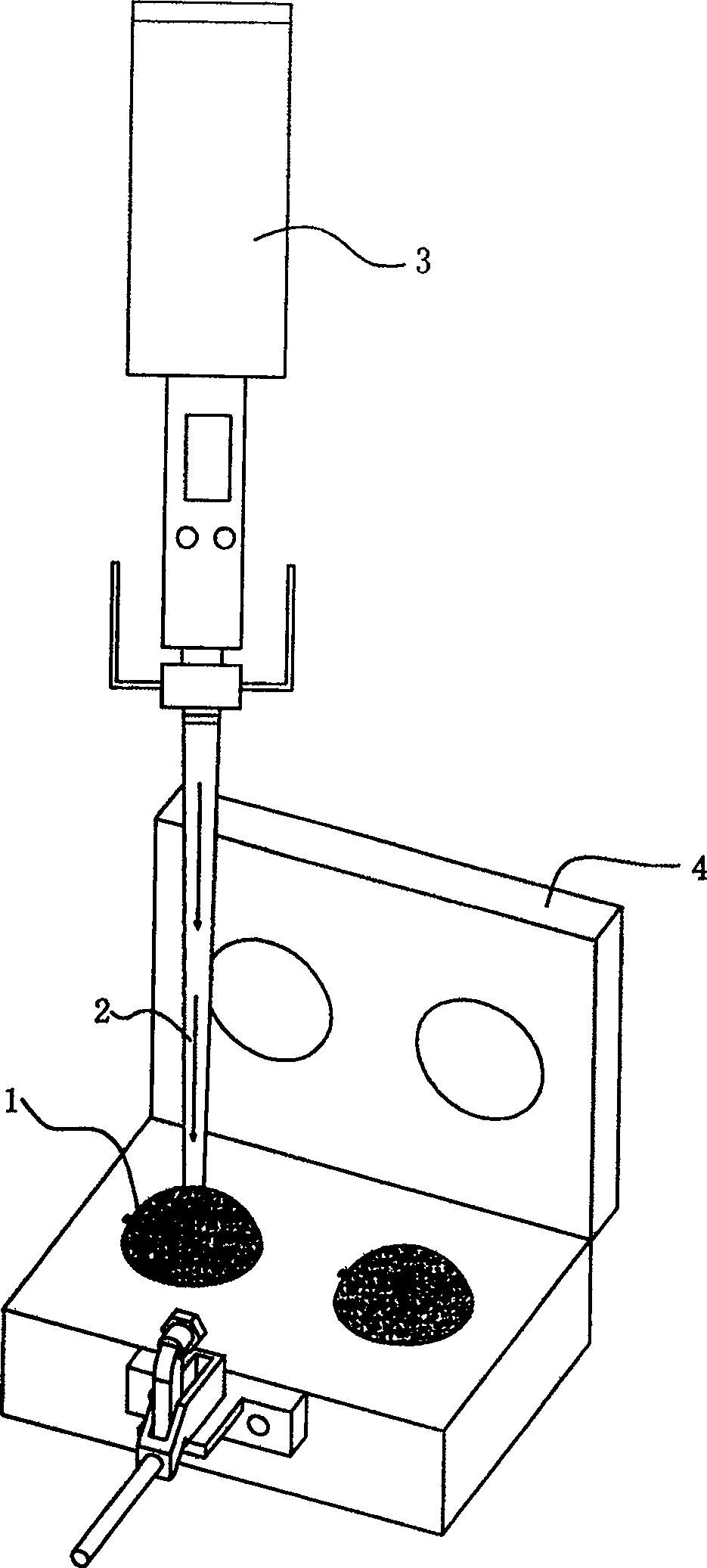

[0020] refer to figure 2 and image 3 , the manufacturing method of solid elastic ball in the present embodiment, comprises the steps:

[0021] a. Inject the PU material into the spherical hollow latex bag with the injection device 3, and the temperature preferably ranges from 20 to 30°C;

[0022] b. Put the latex bag filled with solid PU material into the mold 4, foam and set it for 5-10 minutes, and the temperature is preferably in the range of 40-50°C;

[0023] c. Trim a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com