Construction method for guided way for embedded railway traffic engineering

A technology of embedded rail and traffic engineering, applied in the construction field of embedded rail transit engineering, can solve problems such as improper welding process, poor weldability, and construction difficulty, so as to solve the problem of rail seam welding and reduce the probability of rust , the effect of preventing large areas from rusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

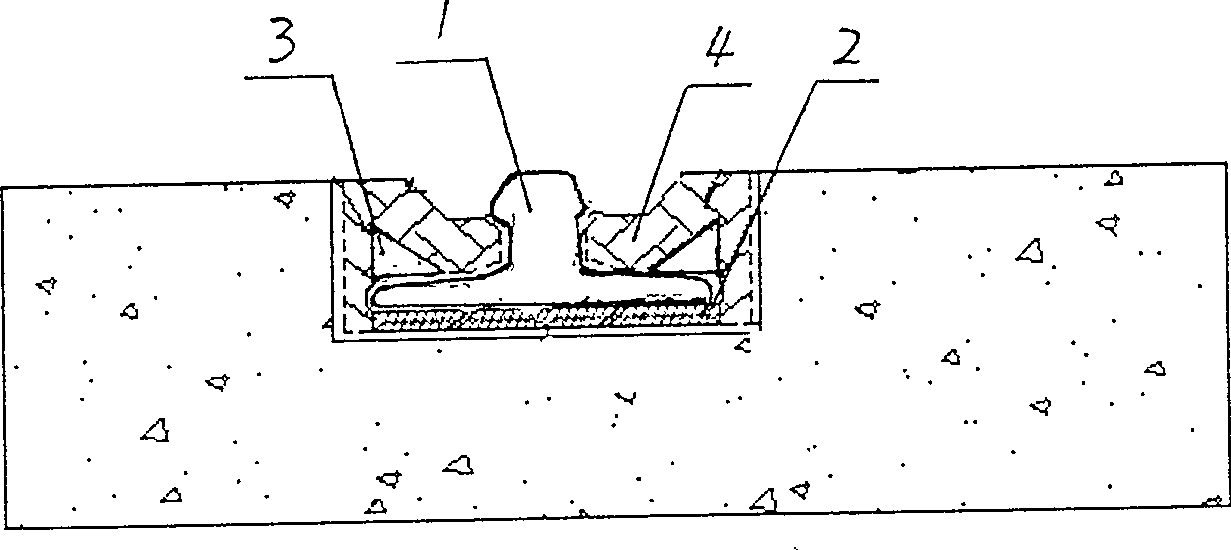

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] The resin material used in the construction method of the embedded track traffic engineering guide rail of the present invention is a series of resin products of Edilon Company, which is mainly divided into three parts: Edilon Primer U90WB, referred to as U90; Edilon Primer21, referred to as P21; Edilon Corkelast To, Referred to as epoxy resin. According to the construction process of the embedded rail transit project, the three products are applied to the guide rail and the rail support groove in sequence, and finally the guide rail is locked on the concrete track bed with resin.

[0037] The construction sketch map of embedded track traffic engineering guide rail of the present invention is as figure 1 As shown, the method includes the following steps:

[0038] 1. Carry out sandblasting or shot blasting derusting treatment on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com