Method for treating arsenic waste solution of hazardous waste by using composite functional bacteria

A technology of composite functional bacteria and hazardous waste, applied in the direction of arsenic compounds, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of expensive adsorbent, difficult regeneration, low efficiency, etc., and achieve the goal of reducing the residual amount of arsenic Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

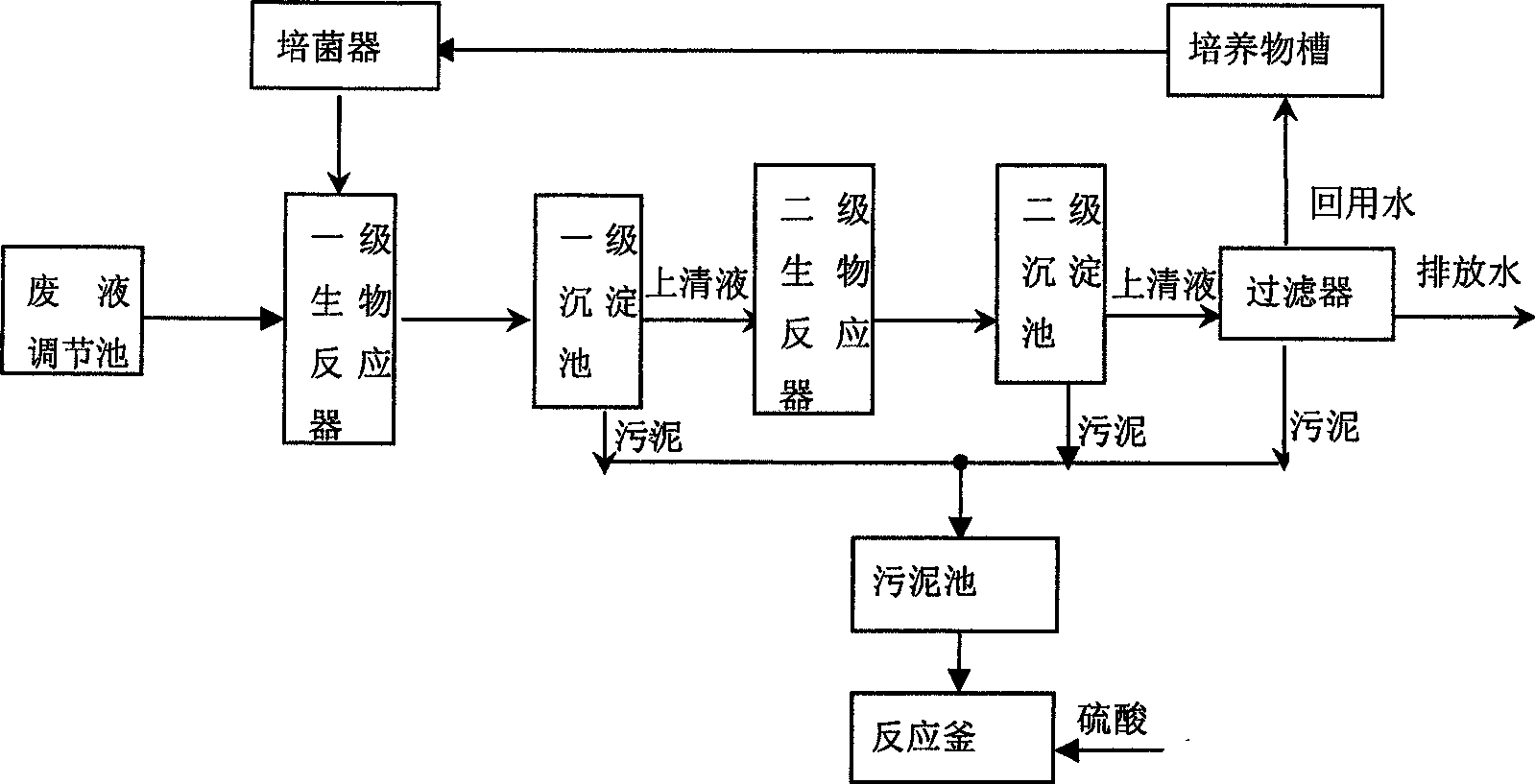

[0046] figure 1 As shown, a specific embodiment of the present invention is: a method for treating hazardous waste arsenic waste liquid with composite functional bacteria, the steps of which are:

[0047] A. Strain selection and ratio: The compound functional bacteria consist of Desulfovibrio Sp., Desulfotomaculum Sp., and Bacillus megaterium Sp., and the ratio of the number of bacteria among the three strains is :60:50:8.

[0048] B. Cultivation of compound functional bacteria: Cultivate the three types of bacteria in step A according to the number of strains in the incubator with nutrients containing Fe, S, C, N, and P. Culture conditions: anaerobic environment, pH7 .0, temperature 30°C, incubation time 36 hours.

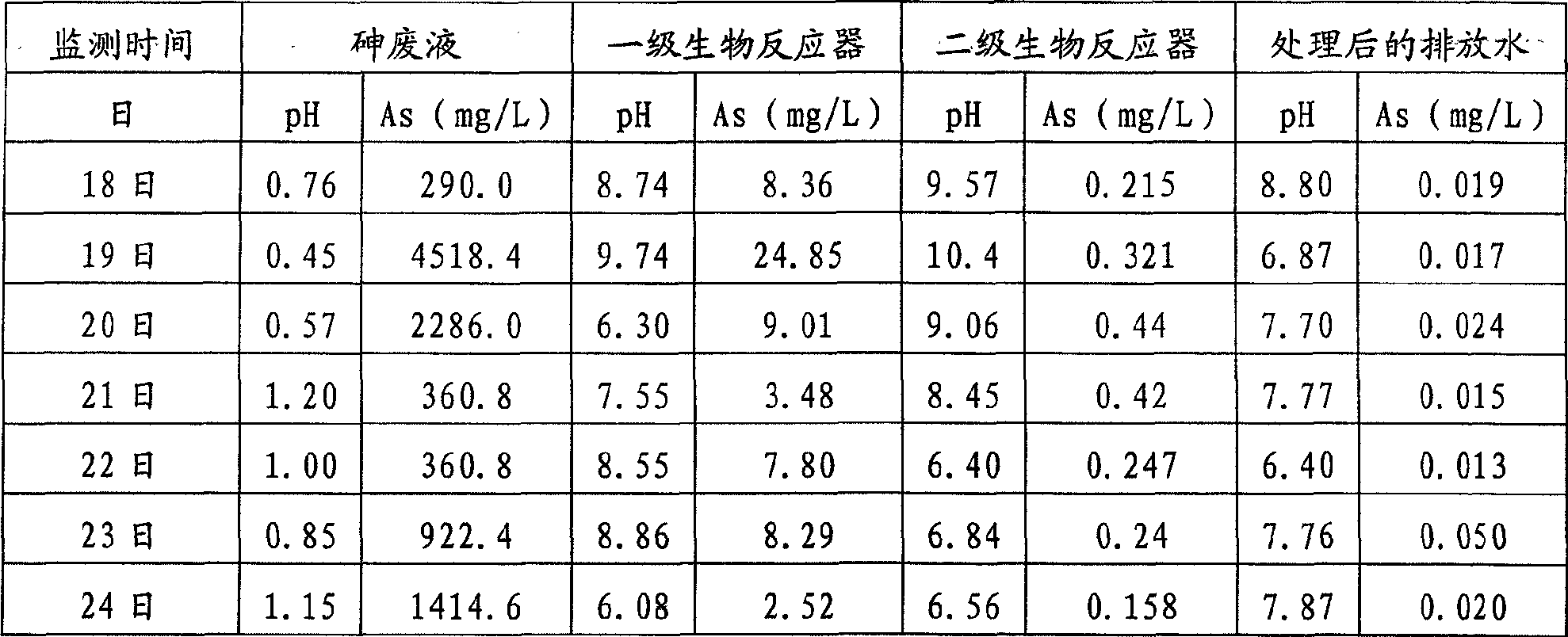

[0049] C. Treatment of arsenic waste liquid: use the composite functional bacteria in the B-step incubator and its metabolites and nutrients as detoxification substances, and combine them with the arsenic waste liquid with a pH of 0.76 to 1.15 and arsenic concen...

Embodiment 2

[0056] This example is basically the same as Example 1, the difference is only:

[0057] The bacterial ratio of the three strains of compound functional bacteria Desulfovibrio Sp., Desulfotomaculum Sp. and Bacillus megaterium Sp. is 56:55:10. Culture conditions: anaerobic environment, pH 7.4, temperature 37°C, culture time 38 hours; arsenic waste liquid with a pH of 2.5-3 and arsenic concentration of 5662-6140 mg / L is used for removal by compound functional bacteria The poison and arsenic waste liquid are mixed and stirred in the primary and secondary bioreactors according to the volume ratio of 5.6-6:1000, and each stage reacts for 20-30 minutes. Add 5 times the volume of 85% sulfuric acid to the sludge and heat it at 170°C for 3 hours to recover As 2 o 3 product. The recovery rate of arsenic is 97%.

[0058] The discharge water was monitored, and the arsenic content in the discharge water was 0.05mg / L, and the pH was 8.5. The total arsenic and pH in the discharged water...

Embodiment 3

[0060] This example is basically the same as Example 1, the difference is only:

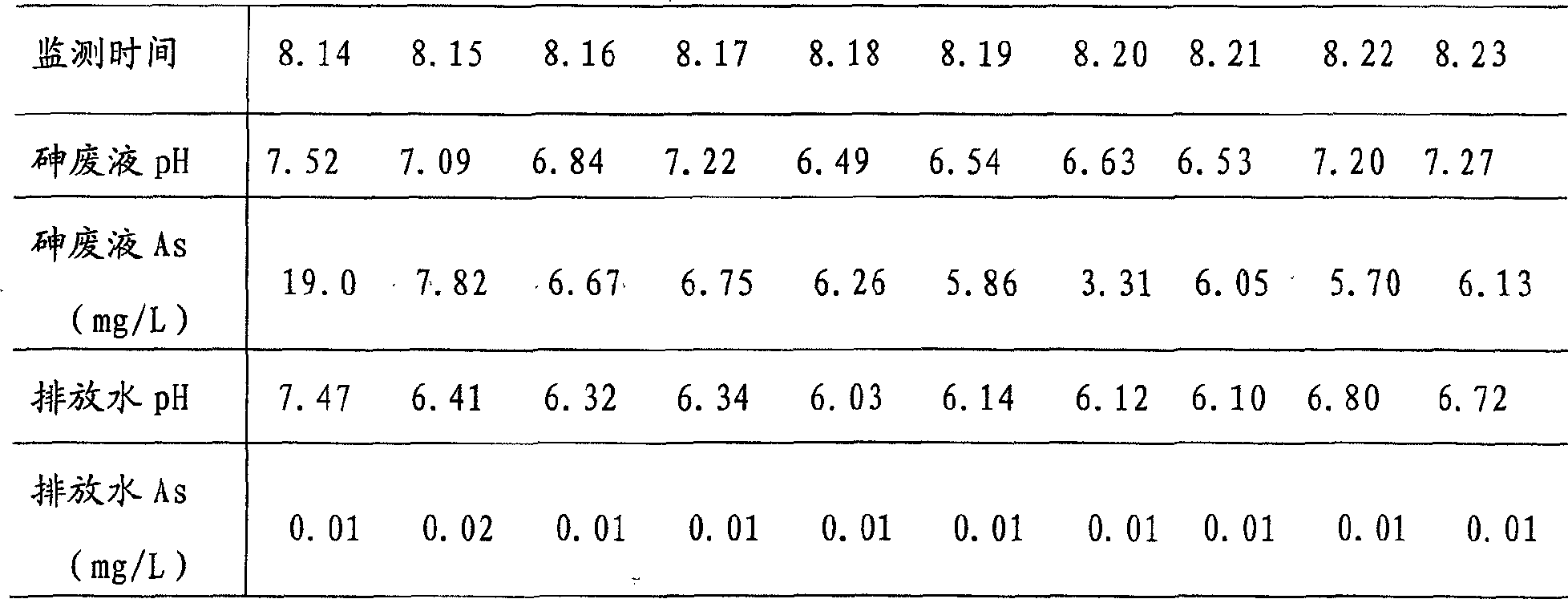

[0061] The ratio of the number of composite functional bacteria Desulfovibrio Sp., Desulfotomaculum Sp. and Bacillus megaterium Sp. was 41:38:5. Culture conditions: anaerobic environment, pH 7.1, temperature 31°C, culture time 32 hours; the arsenic waste liquid with pH 7.8-9.0 and arsenic concentration of 201-1765.1 mg / liter in a workshop of a certain copper mine is used by the method of the present invention Processing 4m per hour 3 Arsenic waste. The detoxified substances and arsenic waste liquid from the compound functional bacteria are mixed and stirred in the primary and secondary bioreactors according to the volume ratio of 4-5:1000, the primary reaction is 5 minutes, and the secondary reaction is 30 minutes. The content of As in the sludge is 8.0%, and As is recovered by the sulfuric acid method, 6.5 times the volume of 95% sulfuric acid is added to the sludge, and it is thermally dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com