Microcavity double-grating and optical-fiber gas sensing system and method

A sensing system and gas sensor technology, used in the fields of safety, analytical instruments, and gas chemistry, which can solve the problems of high cost, great influence of ambient temperature, and inability to compensate for temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

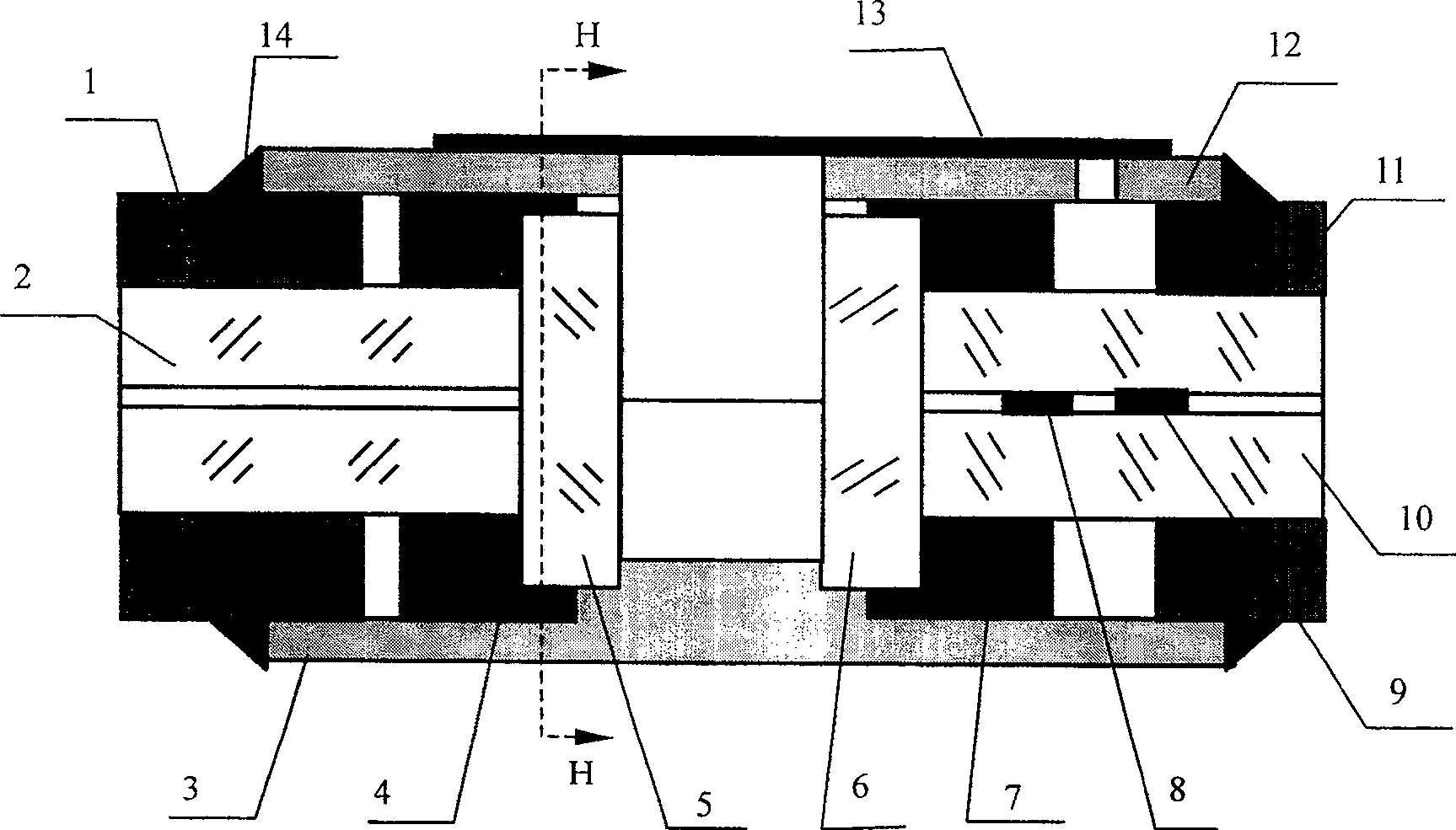

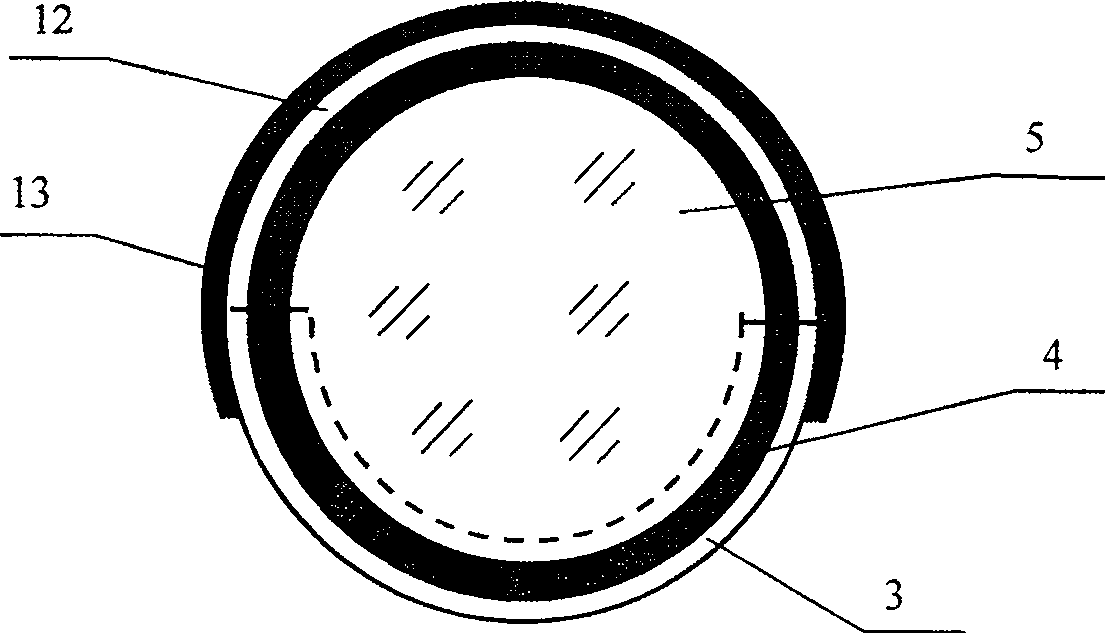

[0049] Further illustrate the present invention below in conjunction with accompanying drawing:

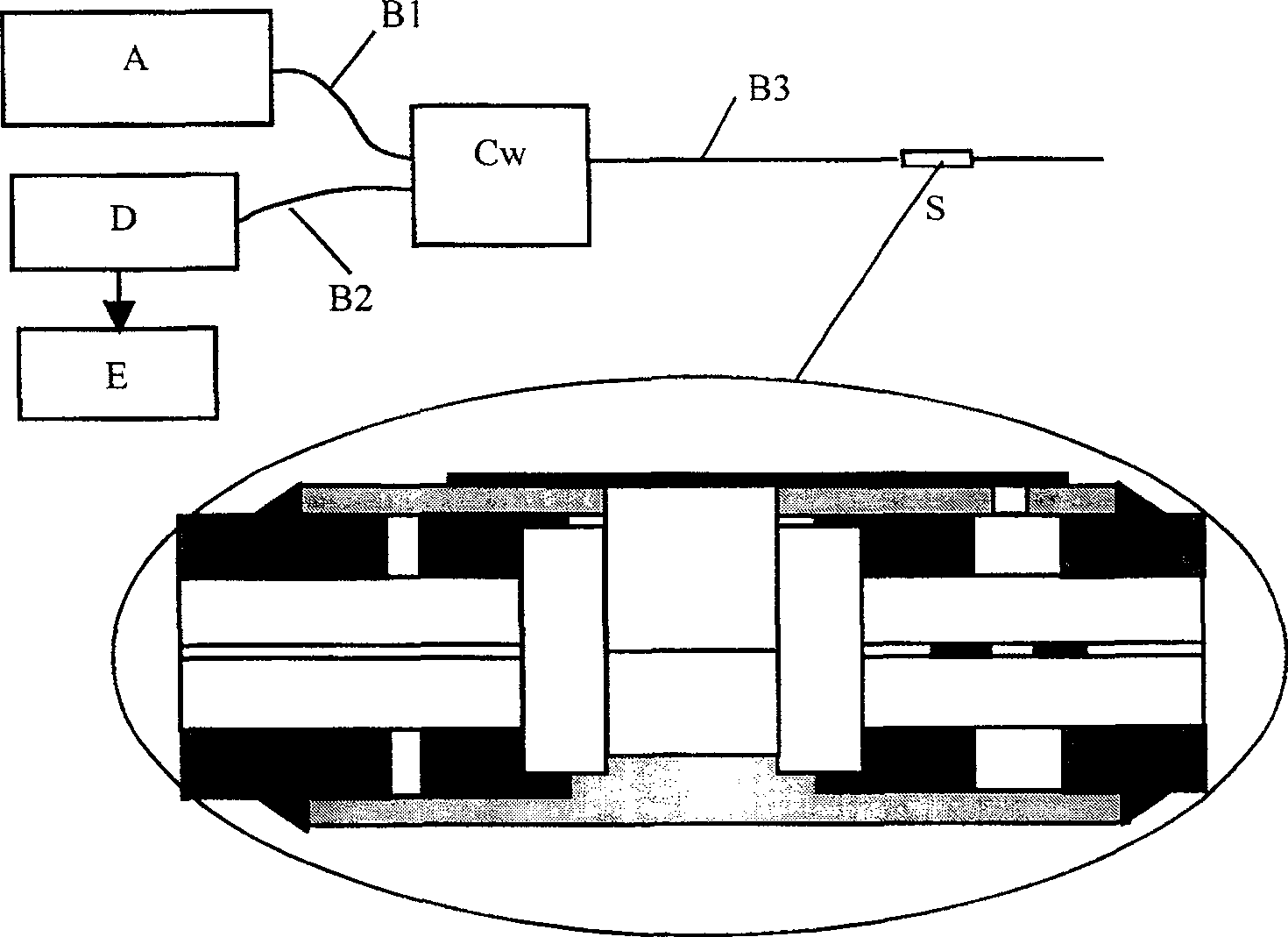

[0050] Such as figure 1 As shown, the sensing system of the present invention is composed of a broadband light source A, optical fibers B1-B3, a broadband coupler Cw, a double-grid optical fiber microcavity gas sensor S, a spectrum demodulator D and a computer E. Its composition method is: a broadband light source A with a center wavelength of 1330nm and a bandwidth of 40nm is connected to an input end of the broadband coupler Cw through an optical fiber B1, and the output end of the broadband coupler Cw is connected to the double-grid optical fiber microcavity gas sensor through an optical fiber B3. At the front end, the other input end of the broadband coupler Cw is connected to the optical fiber input end of the spectral demodulator D through the optical fiber B2, and the data output end of the spectral demodulator D is through the GPIB interface (or standard data interface suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com