Hydraulic experiment device for three-way piece group and the method thereof

A technology of hydraulic testing and tee fittings, which is used in the application of stable tension/pressure to test the strength of materials and the use of liquid/vacuum for liquid tightness measurement. It takes a long time and other problems to achieve the effect of saving raw materials, reducing labor intensity, and convenient loading and unloading workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

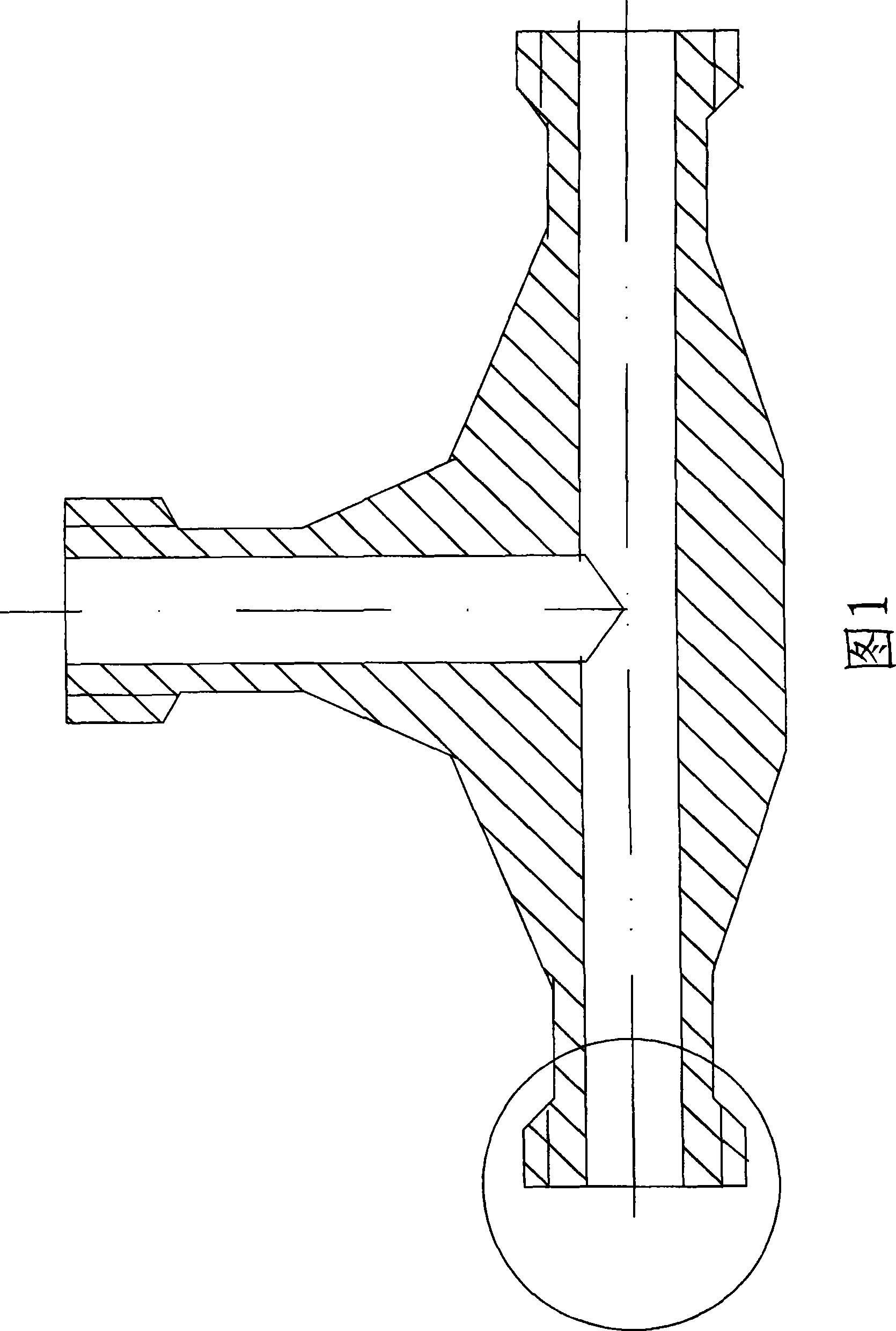

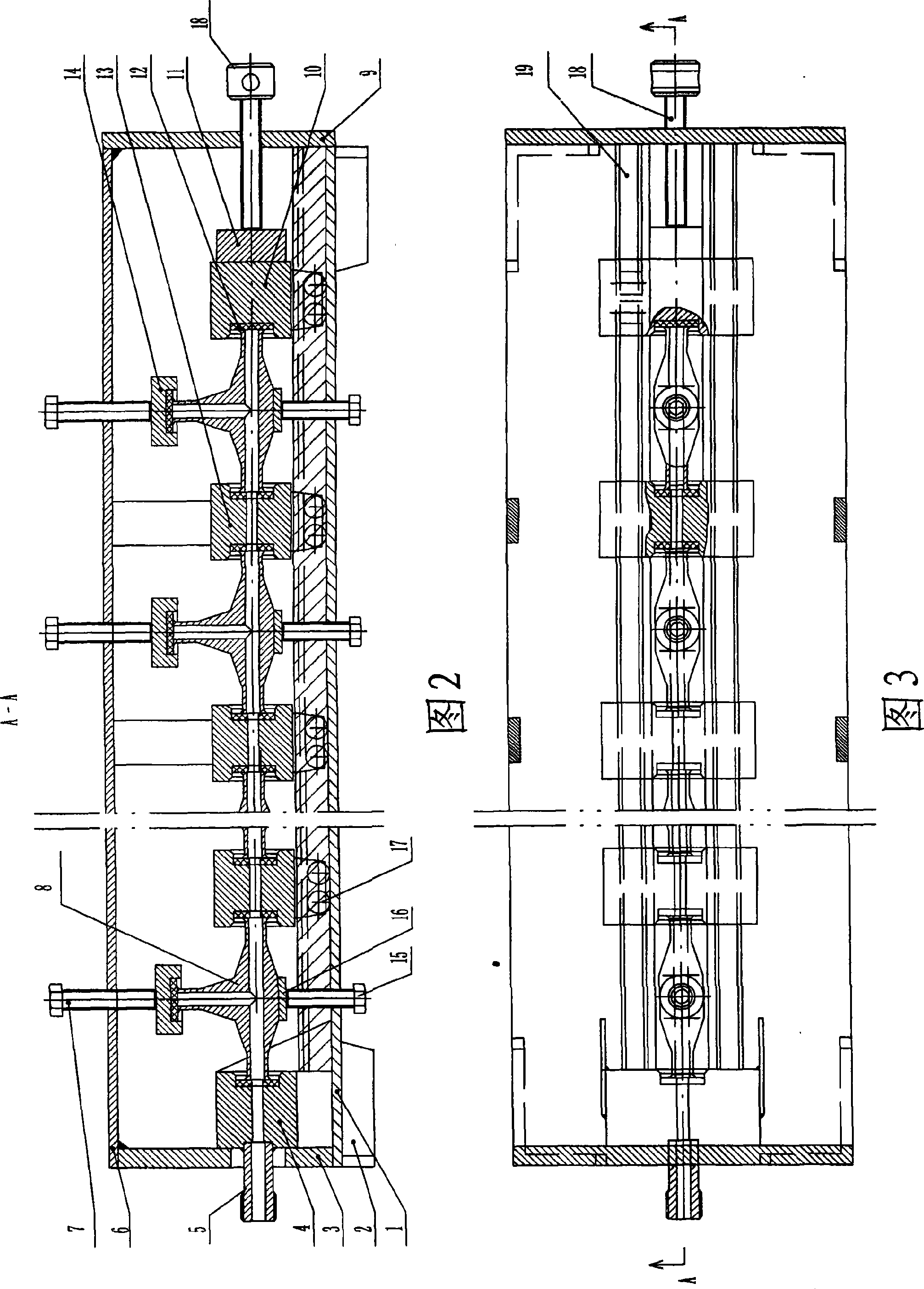

[0022] The three-way hydraulic test device consists of a bottom plate 1, an upper top plate 6, a left plate 3, a right plate 9, a head end block 4, a sliding block 13, an end block 10, a first threaded ejector rod 7, Second threaded push rod 15, T-shaped threaded push rod 18. The bottom ends of the left side plate 3 and the right side plate 9 are fixedly connected to the left and right ends of the base plate 1 respectively, and the upper top plate 6 is fixedly connected to the tops of the left side plate 3 and the right side plate 9 . The bottom four corners of the bottom plate 1 are provided with supporting bases 2 . Bottom plate 1 is provided with two guide rails 19, the bottom surface of sliding block 13 and end block 10 is connected with roller 17, and its roller 17 is installed on the guide rail 19 of base plate 1, makes slide block 13 and end block 10 along guide rail 19 move. The first threaded mandrel 7 and the second threaded mandrel 15 are two groups, and the six s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com