Floating clamping drive device for hobbing gear

A driving device and floating clamping technology, applied in gear tooth manufacturing devices, components with teeth, gear teeth, etc., can solve problems such as poor tightening and positioning effect, complex positioning device structure, and high hobbing defect rate. , to achieve the effect of simple structure, convenient loading and unloading of workpieces, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

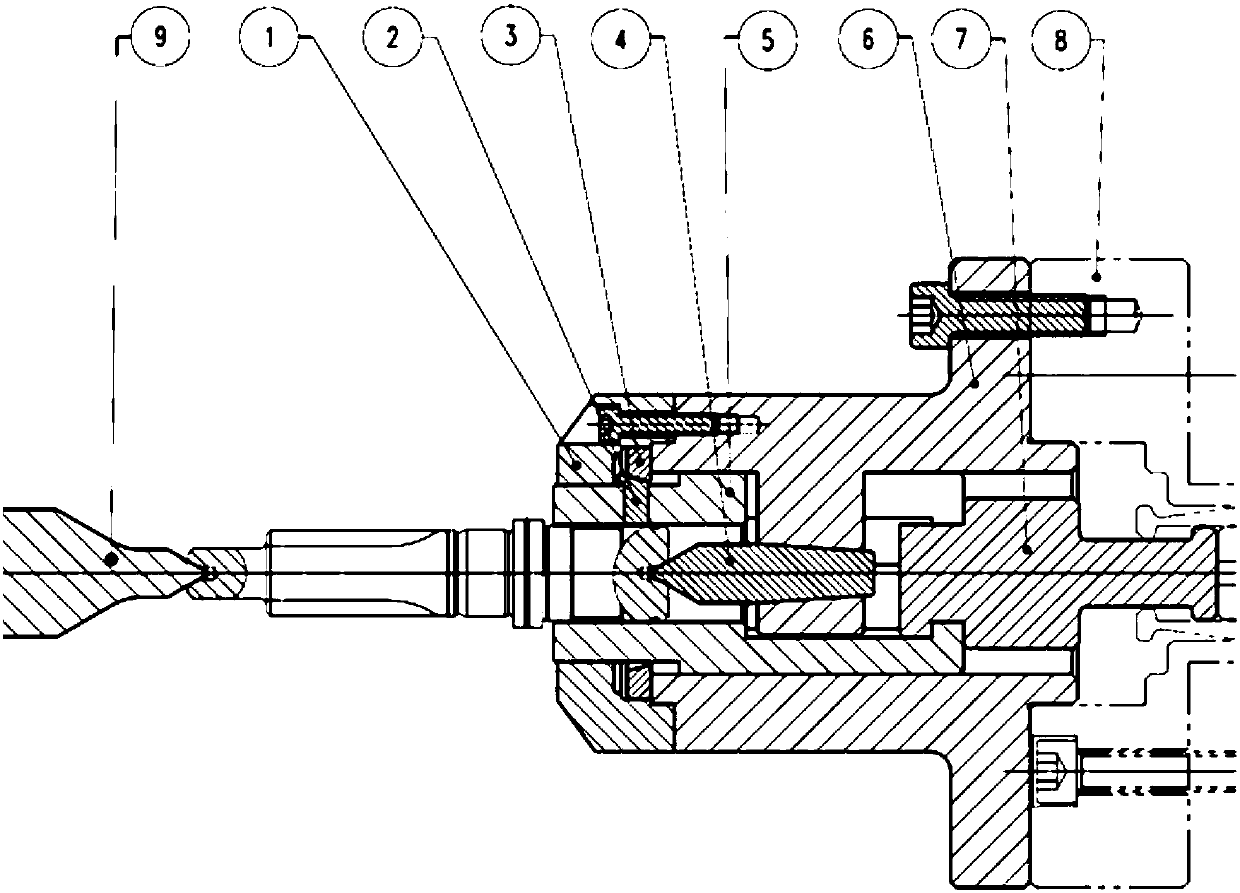

[0017] A floating clamping drive device for gear hobbing, the structure of which is as follows figure 1 As shown, it includes a base 8, a fixture body 6 arranged on the base 8, a wedge-shaped clamping unit arranged in the fixture body 6 for clamping the workpiece, and a wedge-shaped clamping unit arranged at the axis centers at both ends of the workpiece for resisting the two ends of the workpiece. The No. 1 center 9 and the No. 2 center 4 at the end, the axis of the fixture body 6 is provided with an inner cone along the axis, and the taper of the No. 2 center 4 is fixed on the inside of the fixture body 6 . The wedge clamping unit includes a wedge ring 3 arranged at the top of the clamp body 6, a sleeve 5 arranged in the taper hole of the clamp body 6 and coaxial with the clamp body 6, and a sleeve 5 arranged at the top of the sleeve 5 and the wedge ring 3 A plurality of matching wedge blocks 2 and a slider 7 for pulling the sleeve 5 to move along the main axis of the fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com