Safe getter pump of large exhaust speed

A technology of getter pumps and getters, which is applied in the direction of pumps, liquid variable displacement machines, machines/engines, etc., and can solve the problems of inability to fully activate the getter, poor vibration and shock resistance, and weakened gas conductivity, etc. problems, to achieve the effects of saving internal space, improving vibration and shock resistance, and reasonable internal structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

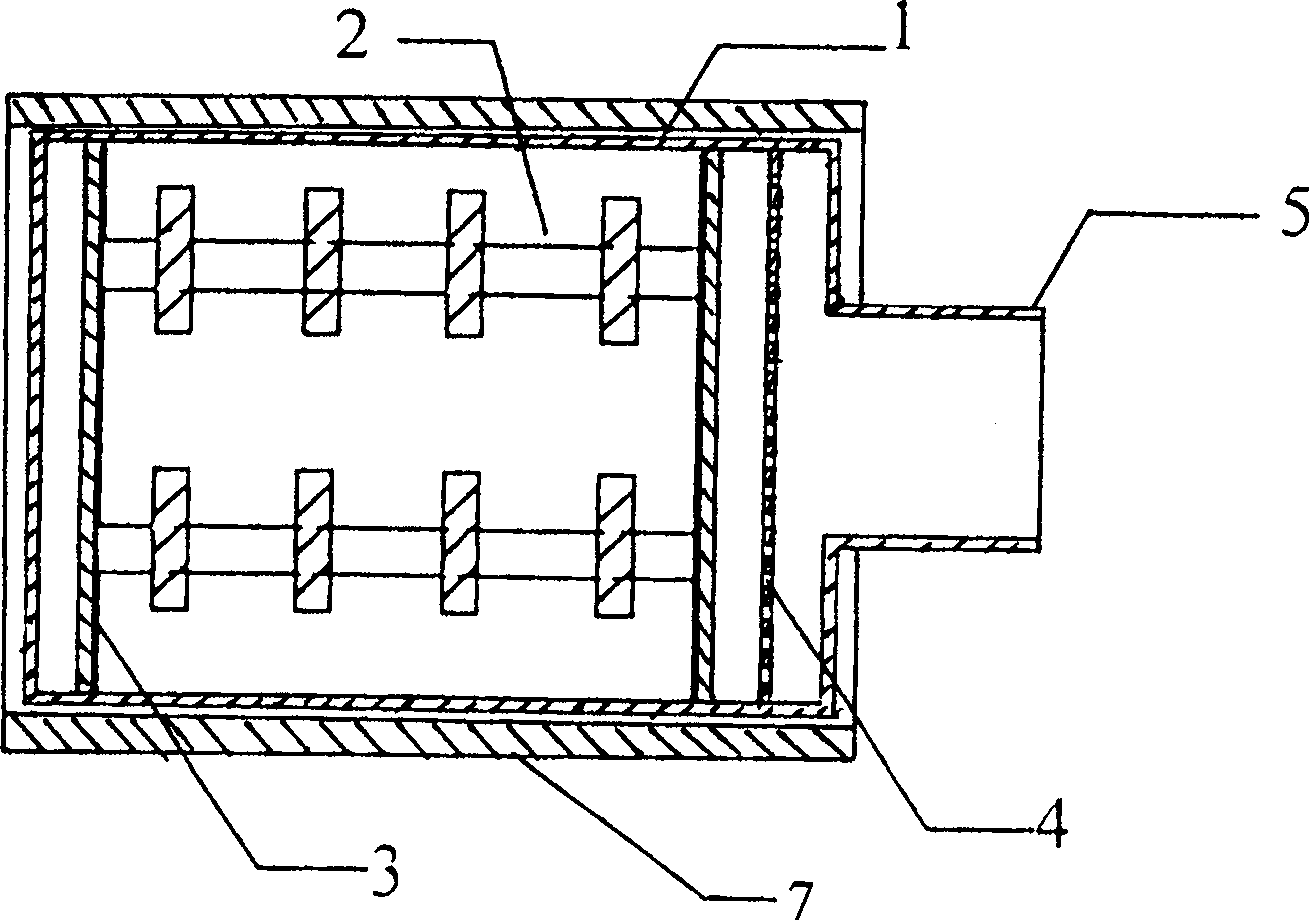

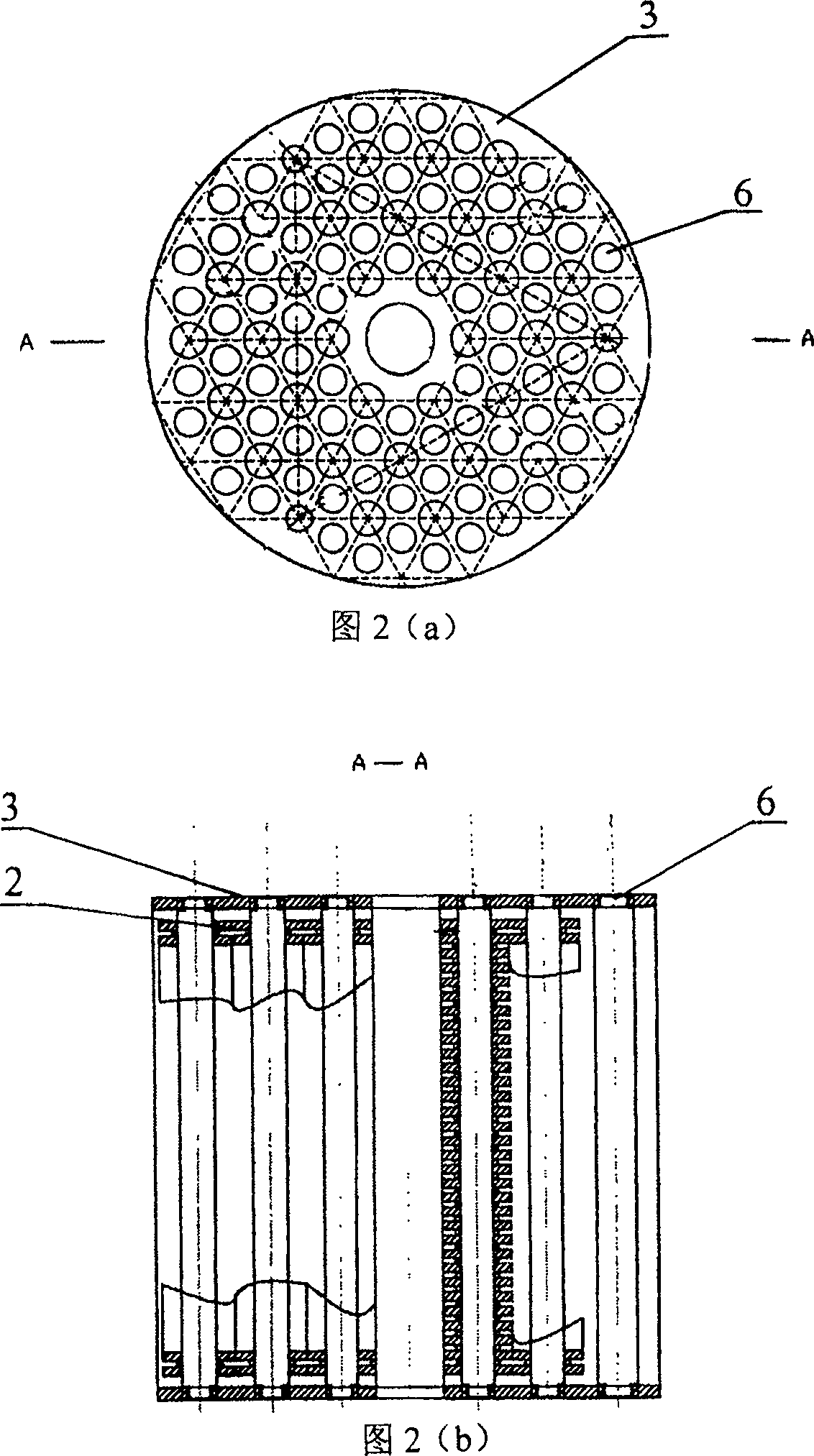

[0040] 0.35g Zr powder, C powder and LaN i 5 The powder mixture was pressed into tablets (inner diameter 6mm, outer diameter 12mm, height 1.3mm) under a pressing pressure of 280MPa, and then sintered at 900°C for 10 minutes to make a getter tablet, and the getter tablet was supported by a stainless steel rod Things are strung together into a getter string 2, which is installed on the positioning plate 3 of the getter pump. The getter in the metal shell 1 is activated by the baking heating method of the external baking heating device 7, and the getter is activated at 500° C. for 30 minutes. 0.35g Zr powder, C powder and LaN i 5 The powder mixture was compressed into tablets under a compression pressure of 280 MPa.

[0041] By controlling the hydrogen desorption temperature of the hydrogen storage alloy to control the flow into the vacuum chamber (the background vacuum is 2×10 -5 Pa, the volume of hydrogen in the cavity is about 0.5 liters), and the vacuum is maintained by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com