Water-containing nitro-amine explosive aqueous phase ingredient solvent density on-line real-time detector and method thereof

An ammonium nitrate explosive, real-time detection technology, applied in the direction of material resistance, etc., can solve the problems of not being suitable for continuous and automatic technical transformation, measuring the concentration of aqueous ammonium nitrate aqueous phase ingredients solution, and slow detection speed, etc., to save measurement steps, The effect of improving batching efficiency and quality and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

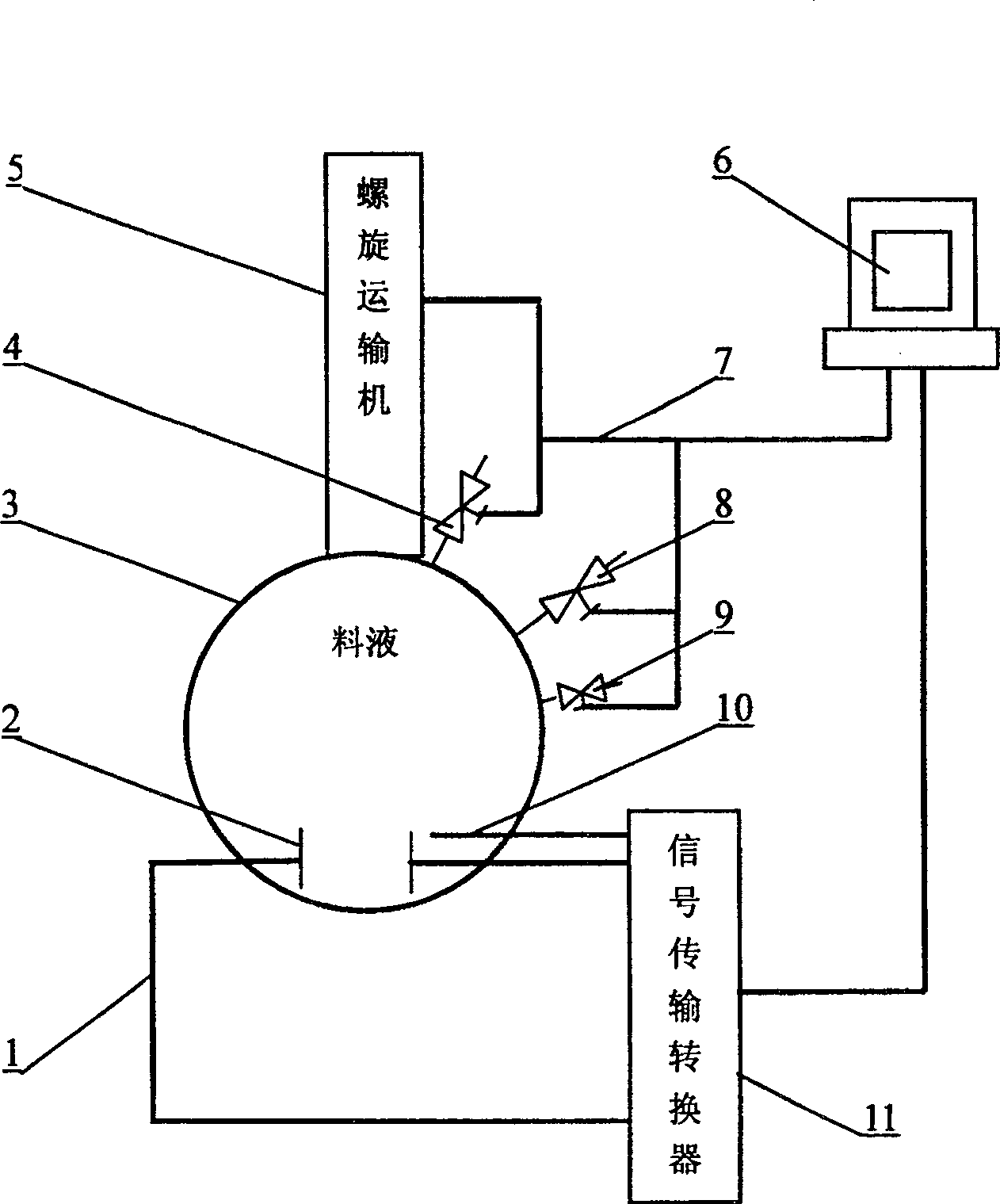

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] combine figure 1 , the online real-time detection device of aqueous ammonium nitrate explosive water phase batching solution concentration of the present invention, comprises the computer 6 that is provided with aqueous ammonium nitrate explosive aqueous phase batching solution concentration-temperature-conductivity standard curve and data processing system, in water phase batching tank 3 Conductivity meter probe 2 and temperature sensor 10 are arranged inside, and this conductivity meter probe 2 and temperature sensor 10 are connected with signal transmission converter 11 respectively, and this signal transmission converter 11 is connected with computer 6; Discharge valve 4, steam valve 8 and water inlet valve 9 are set, and screw conveyor 5 is connected with described water phase batching tank 3 by feeding pipe; Described discharge valve 4, screw con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com