Method and its device for detecting tobacco package

A detection method, tobacco technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of undetectable metal matte craft packaging boxes, etc., achieve the effect of overcoming the influence of background noise, low detection condition requirements, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

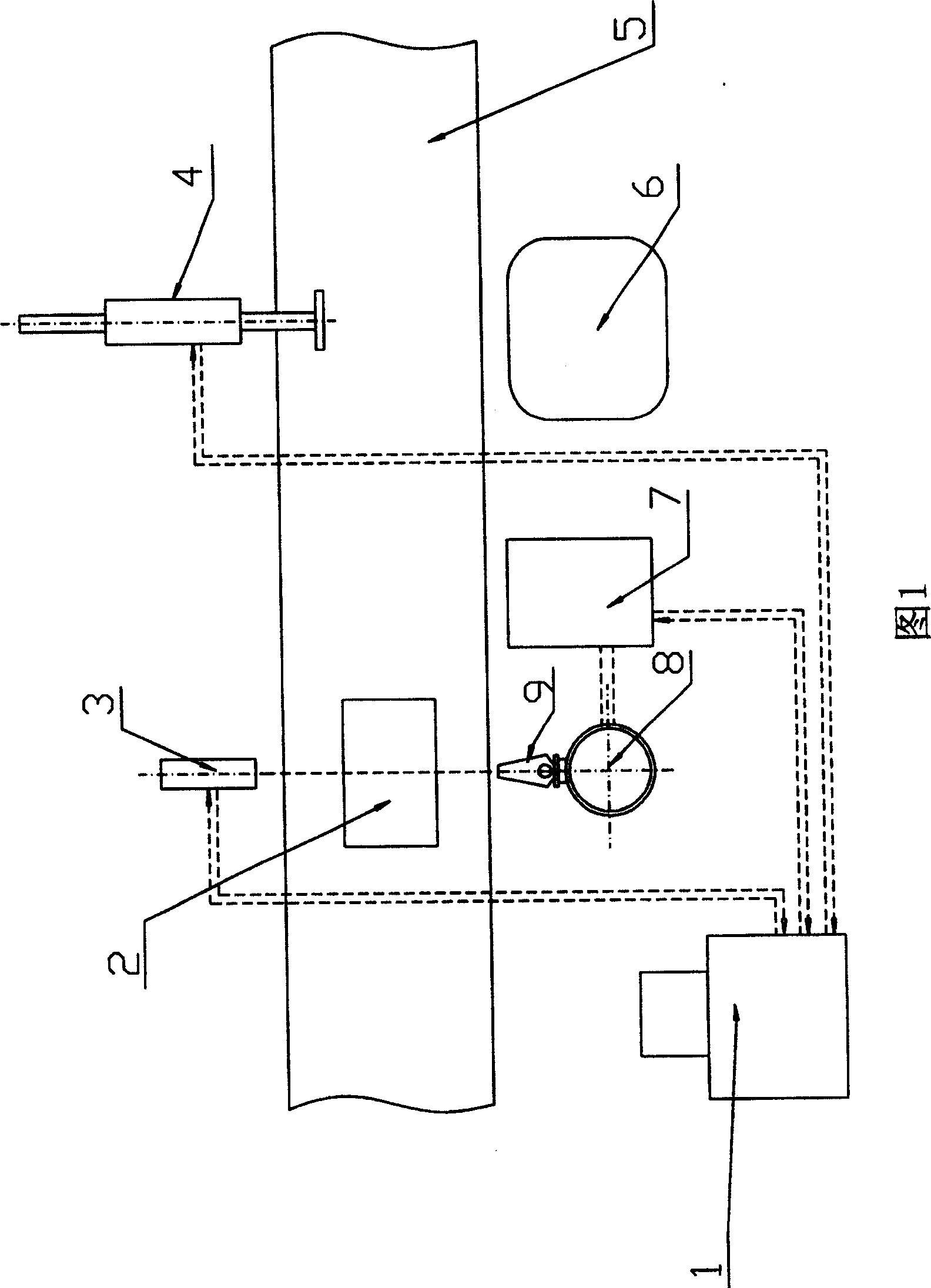

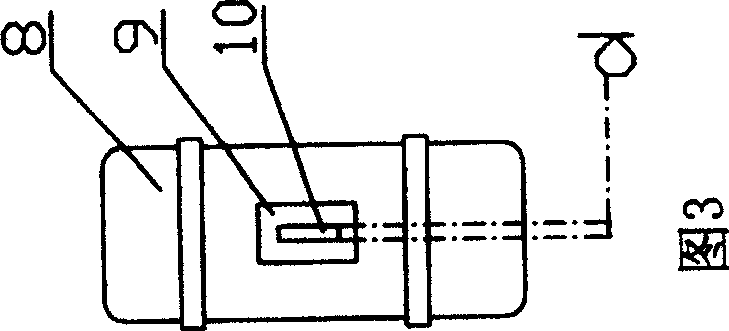

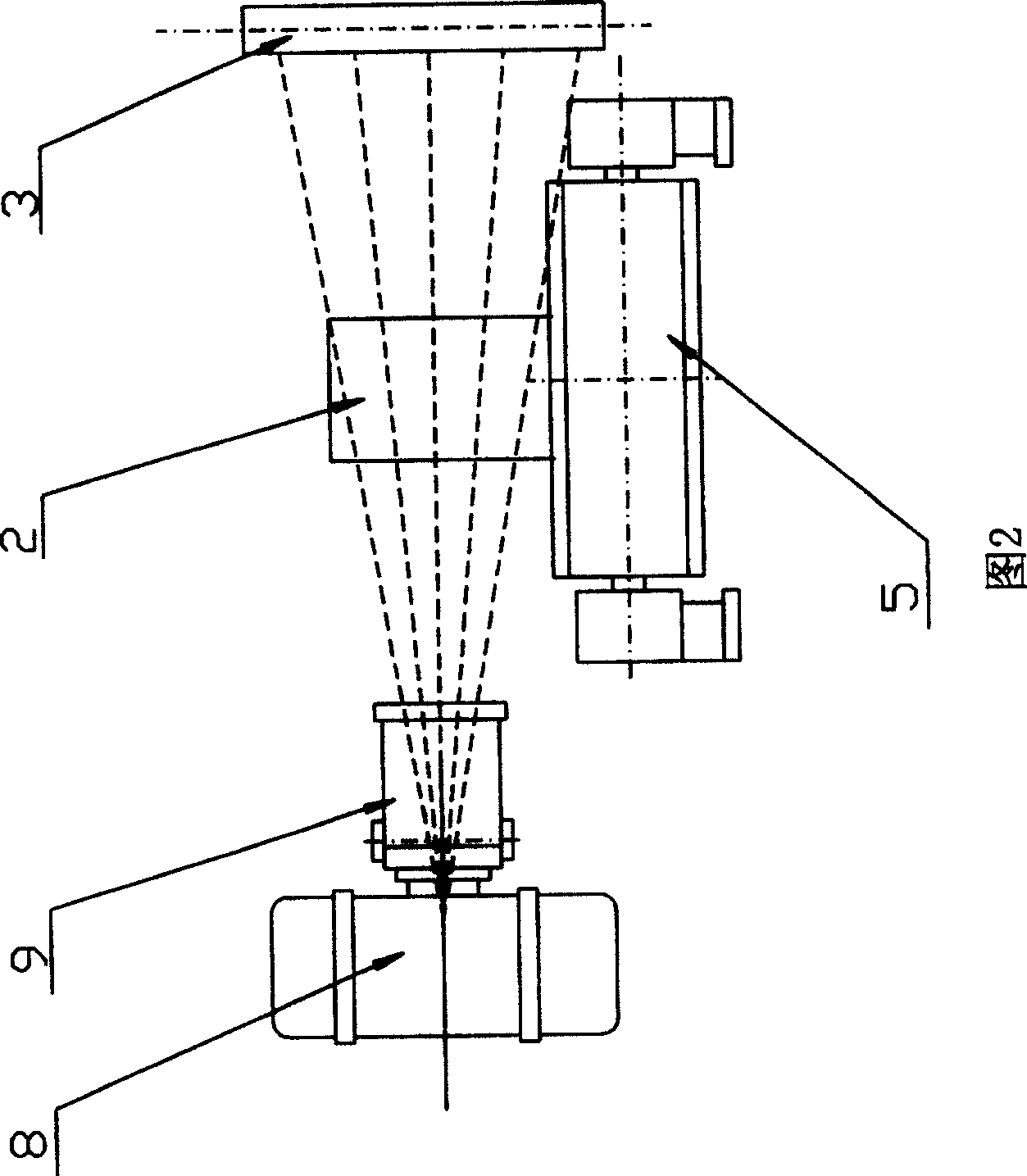

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] X-ray scanning is a method that can directly see through the internal structure of an object and obtain an image of the internal structure of the object. Therefore, it is especially suitable for the detection process of products, especially cigarette packaging. However, the X-ray scanning devices commonly used in other fields are generally surface exposure imaging techniques. That is, the X-rays generated by the X-ray generator are scattered into space, and the scanning area thereof is approximately pyramid-shaped. If this surface exposure imaging technology is used to detect moving objects on the production line, the obtained images will be seriously superimposed. Therefore, ordinary X-ray scanning methods cannot be used for real-time, continuous and dynamic requirements. High detection on the cigarette packaging production l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com