Method for welding two-layered stainless steel heat preservation inner bladder

A welding method and stainless steel technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult welding process, high workpiece defect rate, difficult cleaning, etc., to ensure the quality of weld seam and welding, low cost, The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

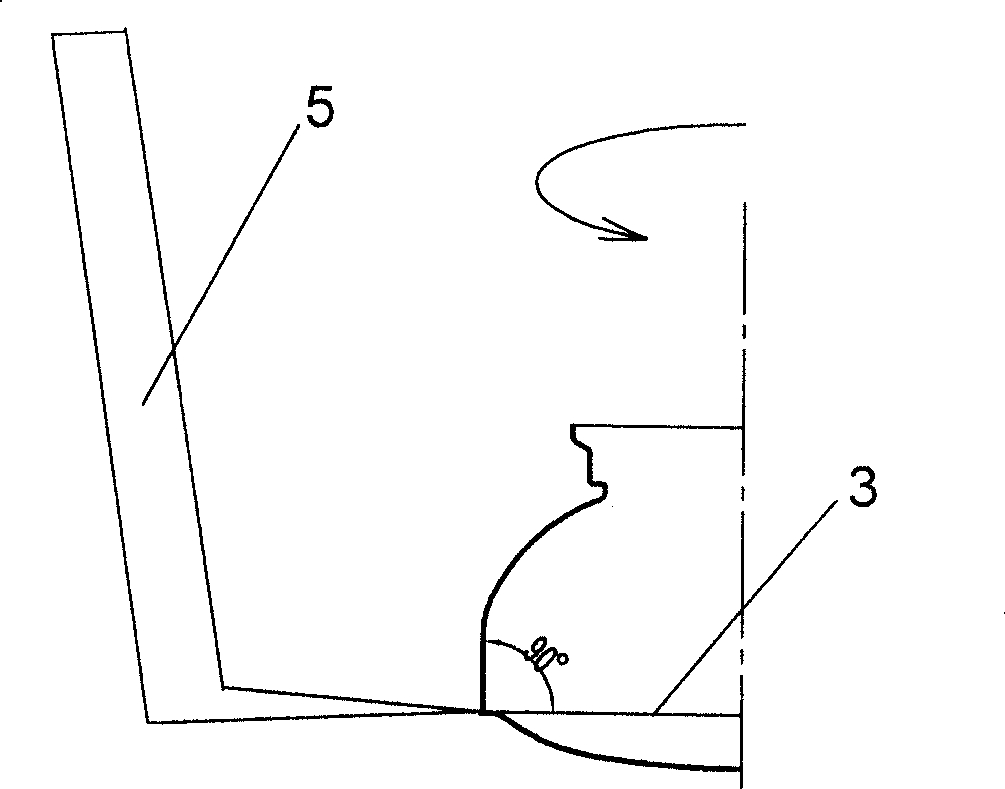

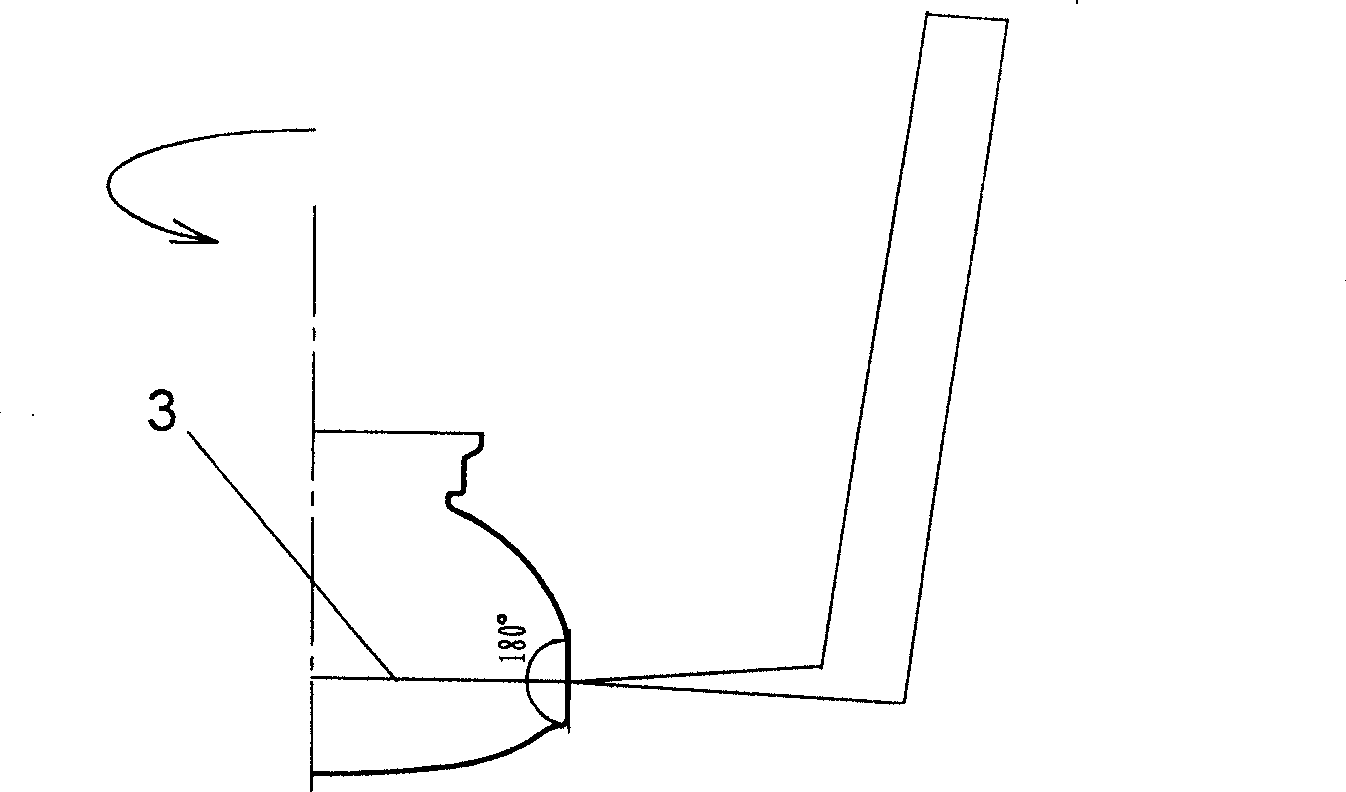

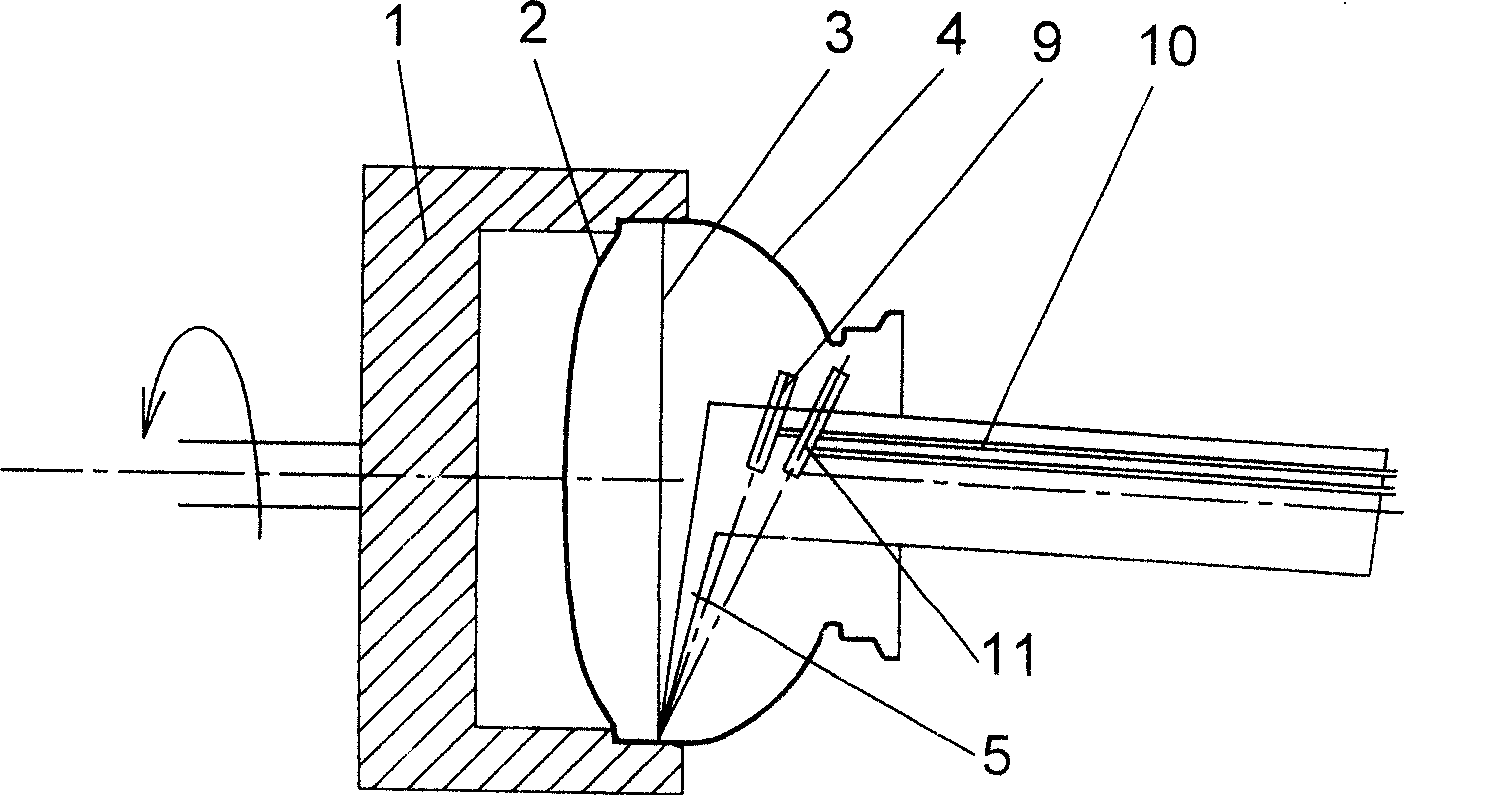

[0017] Hereinafter, an embodiment of the inner container of the welded stainless steel heat preservation pot of the present invention will be described in detail with reference to the drawings.

[0018] When welding the inner pot of stainless steel pot, follow the steps below:

[0019] The interface between the stainless steel tube 4 and the bottom 2 of the tube is degreased with acetone;

[0020] The bladder 4 and the bladder bottom 2 are put into the rotatable master mold 1 made of copper or aluminum material, so that the outer wall of the butted bladder and the bladder bottom are closely attached to the inner wall of the master mold. Because stainless steel has a great affinity for oxygen, if argon-filled protection is not used, the weld metal is prone to oxidation during the welding process, resulting in welding defects. Tungsten argon arc welding is a high-quality precision welding technology and an ideal welding method for welding thin-walled stainless steel. Therefore, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com