Production of multi-layer circuit board of built-in passive assembly

A technology of multi-layer circuit boards and passive components, which can be used in the manufacture of multi-layer circuits and the assembly of printed circuits with electrical components, which can solve the problems of poor electrical accuracy and complex processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0042] The following icons are for simple illustration only, and are not drawn according to the actual size, that is, they do not reflect the actual size and characteristics of each layer in the multilayer circuit board structure.

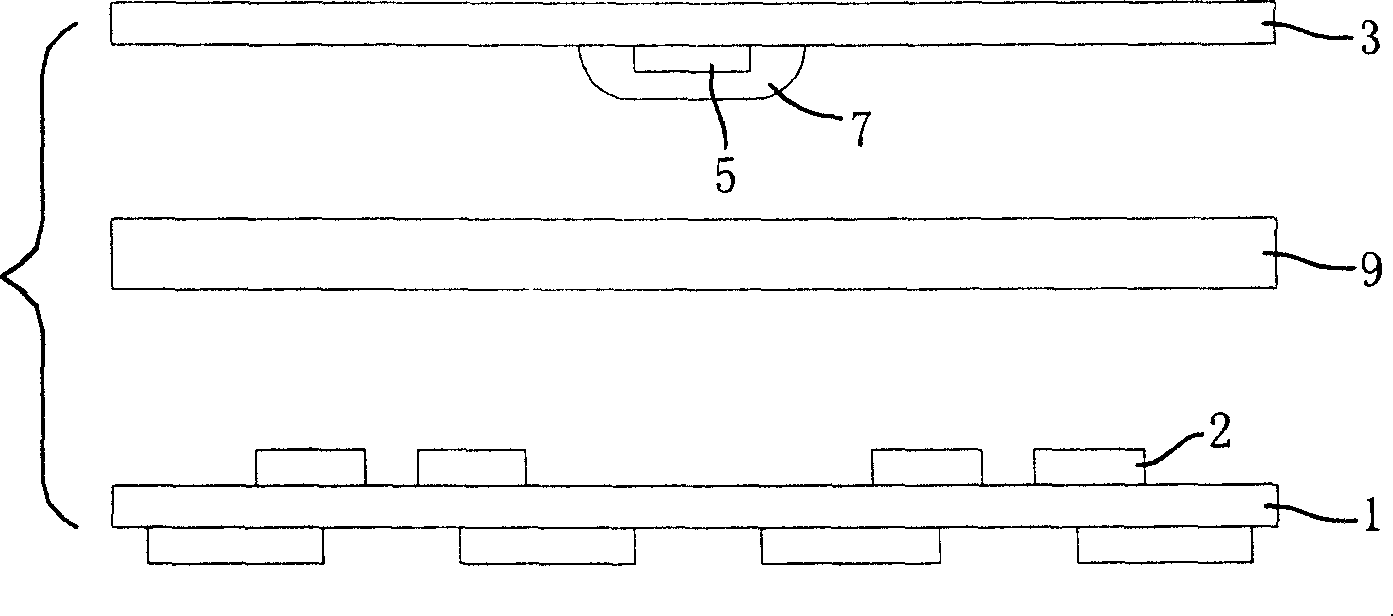

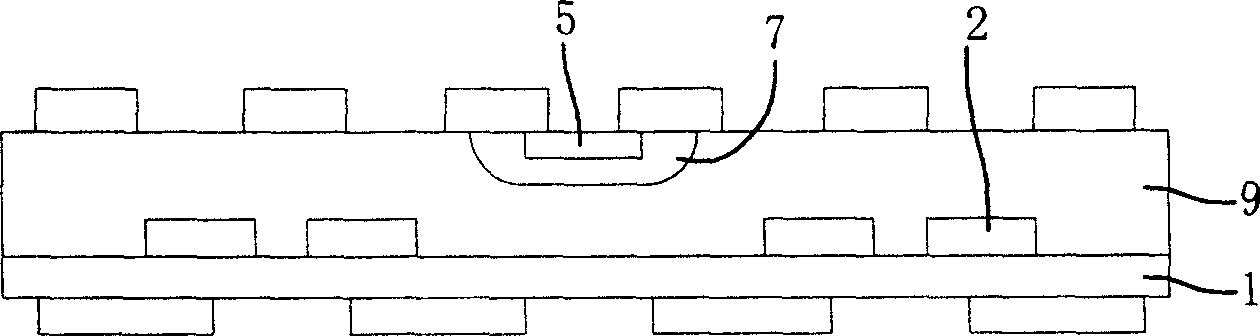

[0043] see Figure 2A to Figure 2E , a cross-sectional view of the manufacturing process of the first preferred embodiment of the multilayer circuit board with embedded passive components of the present invention.

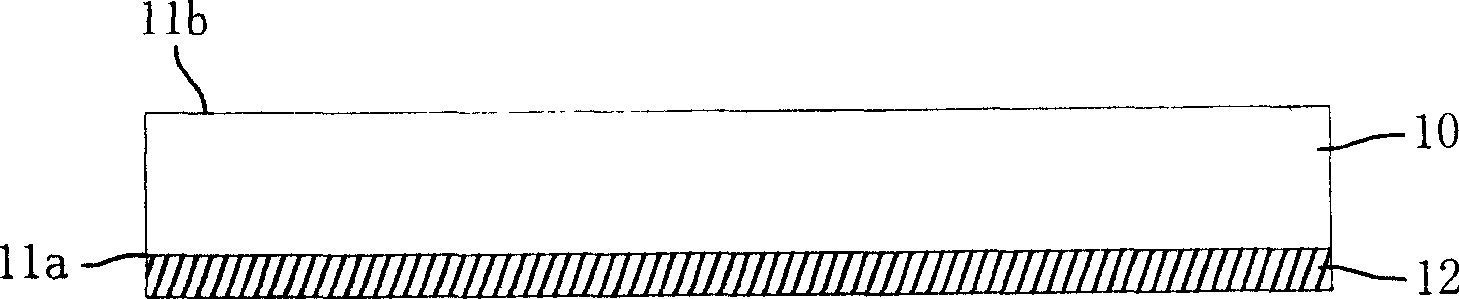

[0044] like Figure 2A As shown, a single-layer board is firstly provided, the single-layer board includes a dielectric layer 10 and a first conductive foil 12, the dielectric layer 10 has a first surface 11a and a second surface 11b, and the first conductive foil 12 is arranged on the first on the surface 11a.

[0045] The material of the dielectric layer 10 is an insulating material, which may be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com