Gasoline purification agent composition

A technology of gasoline detergent and composition, which is applied in the field of gasoline detergent composition, can solve problems such as poor oil supply, reduced engine power, non-gas leakage, etc., to help fuel combustion, improve engine power, reduce The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0048] The gasoline cleaner composition includes:

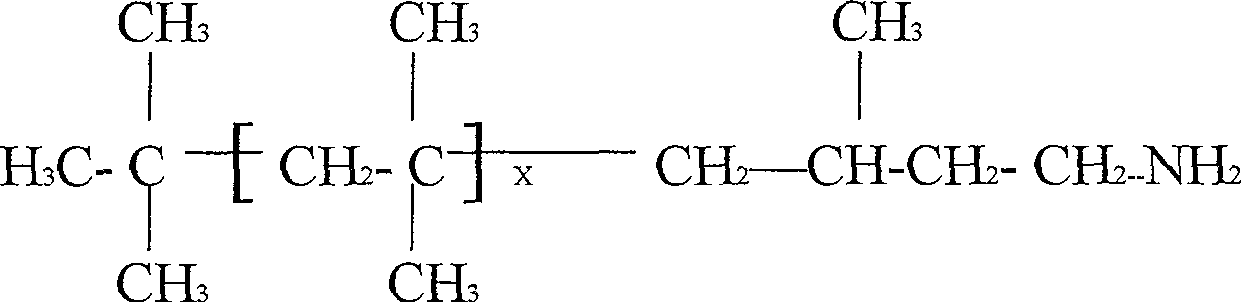

[0049] (1) 15 grams of polyisobutenamine having the structural formula of component (a) with a number average molecular weight of 1000.

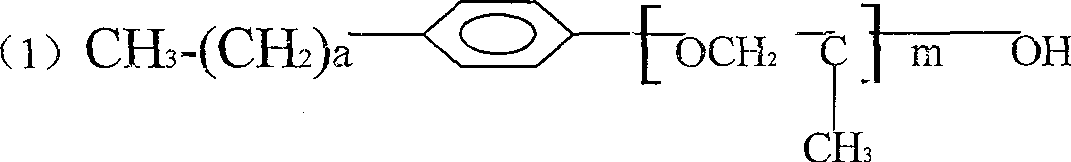

[0050] (2) 7 grams of alkylphenol polyether having the structural formula of component (b) with a number average molecular weight of 1200.

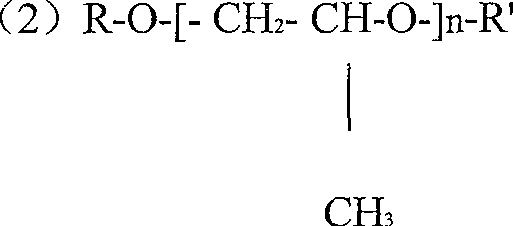

[0051] (3) 5 grams of polyoxyethylene ether with a number average molecular weight of 700 and the structural formula of component (c)

[0052] The above components are made after simple compounding in the blending kettle.

example 2

[0054] The gasoline detergent composition includes:

[0055] (1) 16 grams of polyisobutenamine having the structural formula of component (a) with a number average molecular weight of 1000.

[0056] (2) 7 grams of alkylphenol polyether having the structural formula of component (b) with a number average molecular weight of 1200.

[0057] (3) 6 grams of polyoxyethylene ether with a number average molecular weight of 700 and the structural formula of component (c)

[0058] (4) 7 grams of polyisobutylene having component (d) with a number average molecular weight of 960.

[0059] The above components are made after simple compounding in the blending kettle.

example 3

[0061] The gasoline detergent composition includes:

[0062] (1) 17 grams of polyisobutenamine having the structural formula of component (a) with a number average molecular weight of 1000.

[0063](2) 8 grams of alkylphenol polyether having the structural formula of component (b) with a number average molecular weight of 1100.

[0064] (3) 5.5 grams of polyoxyethylene ether with a number average molecular weight of 700 and the structural formula of component (c)

[0065] The above components are made after simple compounding in the blending kettle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com