Universal rotation hinge

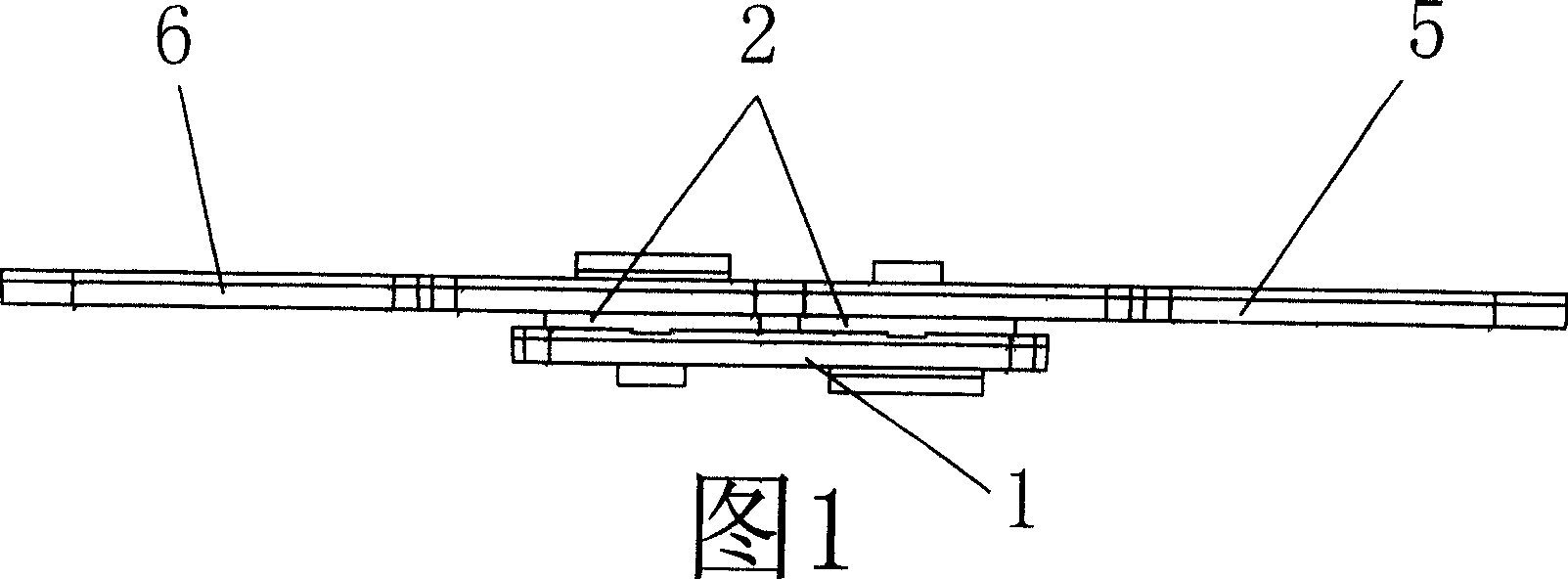

A kind of rotating hinge, all-purpose technology, applied in the direction of furniture connection, connecting components, stools, etc., can solve the problem of noise, etc., to achieve the effect of large rotation angle range, stable rotation, no noise support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

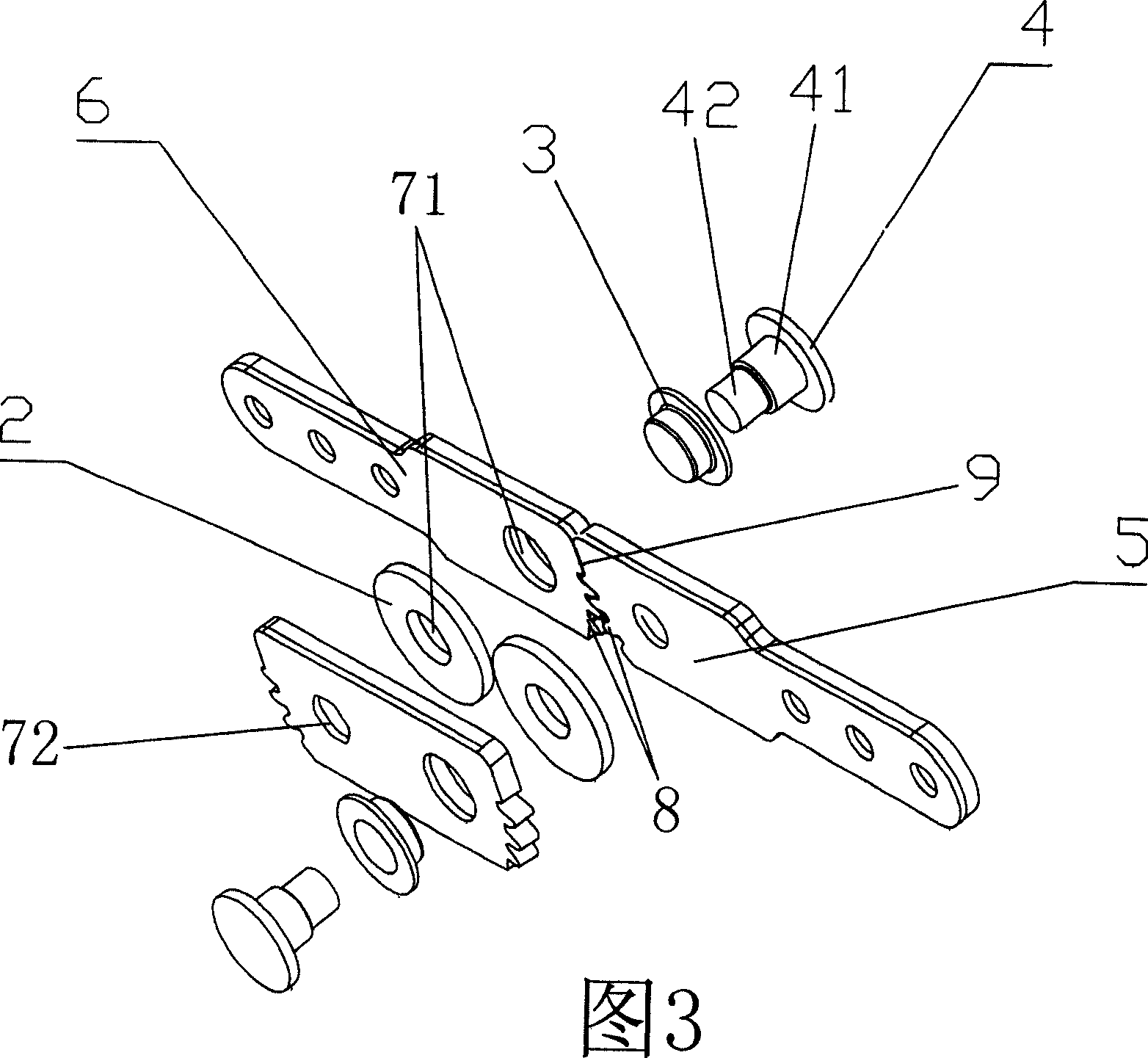

[0021] see Figure 4 ~ Figure 6, the left connecting plate 6 and the right connecting plate 5 in Embodiment 1 are the same as the basic form, but the connecting device 1 adopts a first-level connecting device, including the upper toothed plate 10 of the first-level connecting device and the first-level connecting device The lower toothed plate 11, the upper toothed plate 10 of the first level connection device is the same as the lower toothed plate 11 of the first level connection device, and both ends are provided with supporting surfaces 9, The gear surface 8, the rotating shaft hole 71, the small rotating shaft hole 72, the upper toothed plate 10 of the first-stage connecting device and the lower toothed plate 11 of the first-stage connecting device are movably connected by the rotating shaft in the same manner as in Embodiment 1, and the first-stage connection The upper toothed plate 10 of the device is on the same plane and engaged with the left connecting plate 6, the lo...

Embodiment 2

[0023] see Figure 7 ~ Figure 9 , the left connecting plate 6 and the right connecting plate 5 in Embodiment 2 are identical to the basic form, but the connecting device 1 adopts a secondary connecting device, including the upper toothed plate 10 of the first connecting device, the lower tooth of the first connecting device Shaped plate 11, the upper toothed plate 12 of the second level connecting device, the lower toothed plate 13 of the second level connecting device, the upper toothed plate 10 of the first level connecting device, the lower toothed plate 11 of the first level connecting device, the second The upper toothed plate 12 of the stage connecting device and the lower toothed plate 13 of the second stage connecting device are the same, and both ends are provided with supporting surfaces 9, gear surfaces 8 and shaft holes 71 that match the left connecting plate 6 and the right connecting plate 5, The small shaft hole 72, the connection mode between the left connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com