Tooth brush

A technology for a toothbrush and a covering part, which is applied to brushes, brush bodies, instruments, etc., can solve the problems of poor anti-skid property of the handle part and poor chirality of the toothbrush, so as to not easily adhere to dirt, improve the chirality and Anti-slip, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~4

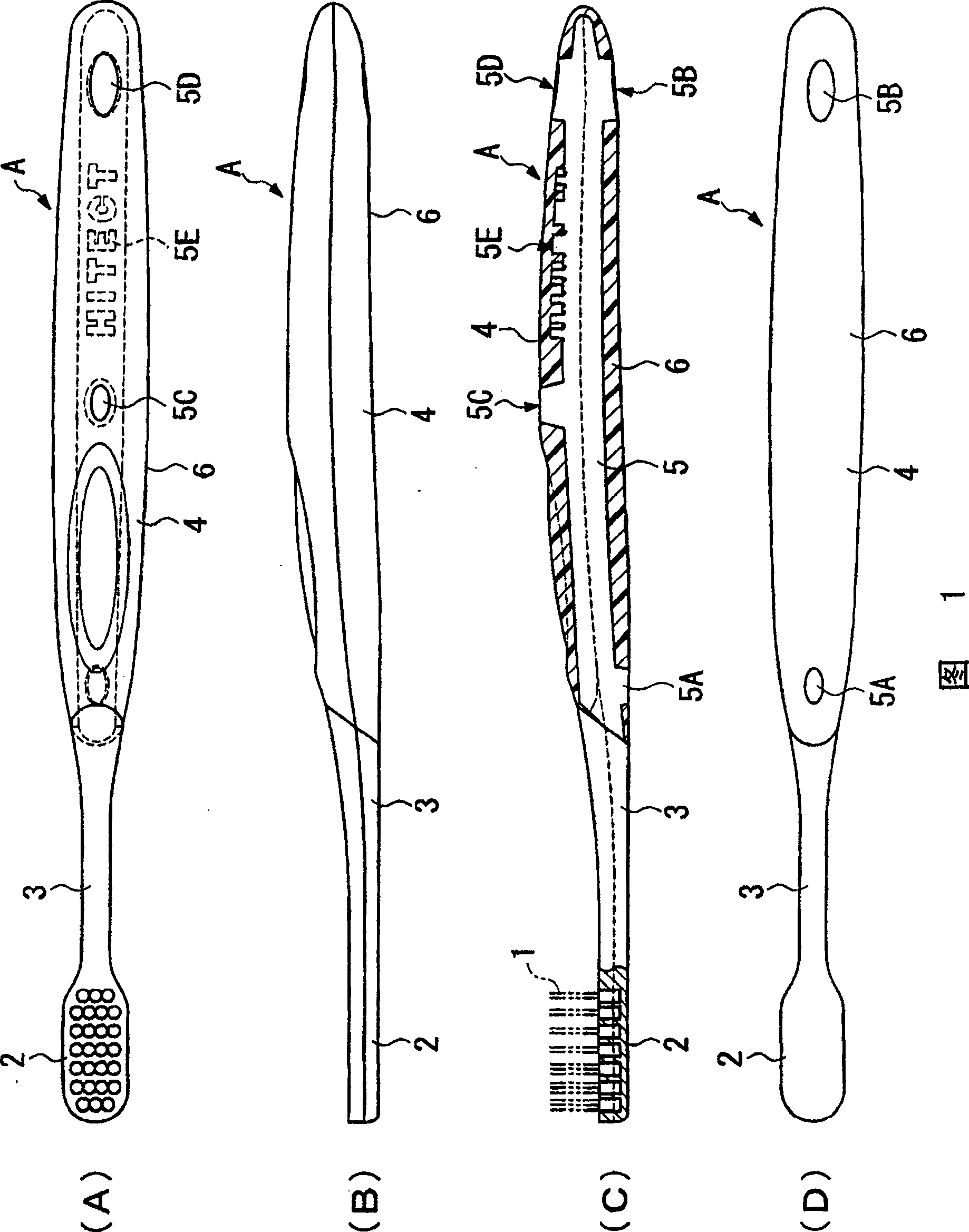

[0081] As the above-mentioned styrene-based elastomer resin, a resin having a rubber hardness of 20 ("Thermolast K" of KRAIBURG, Germany) was used. In addition, the thickness of the covering portion formed by molding the covering material was set to 3 mm. In addition, the coefficient of friction of the surface of the covering part was set to three types: 0.5, 1.0, and 2.0, and the ratio of the surface area of the covering part to the surface area of the gripping part was set to three types: 50%, 70% and 90%, thereby manufacturing examples. 1-3 and the toothbrush samples of Comparative Examples 1-4.

Embodiment 4~7 and comparative example 5~8

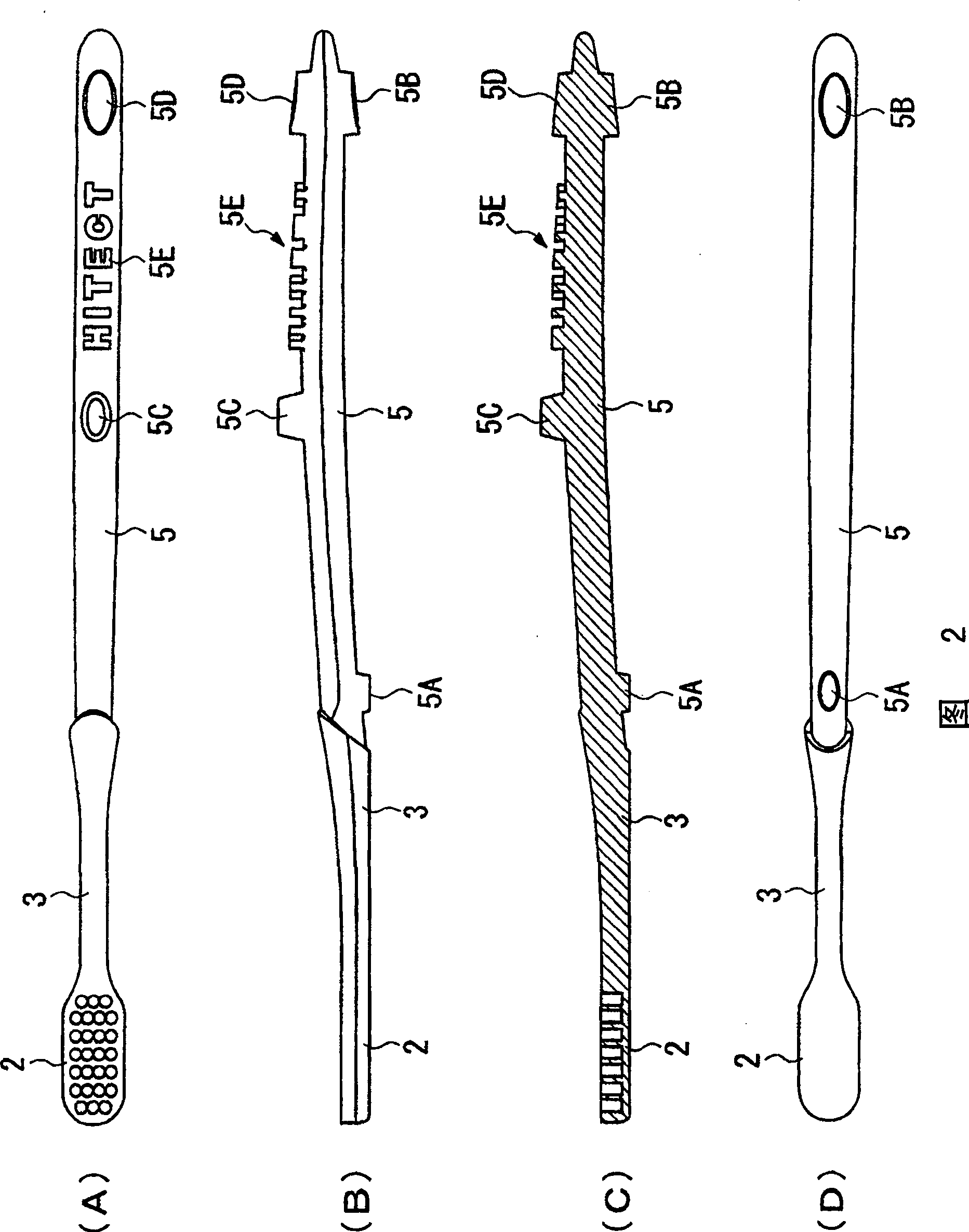

[0097] Next, the ratio of the surface area of the covering portion to the surface area of the gripping portion was set to 90%, and the rubber hardness of the styrene-based elastomer resin used was set to 15, 40, and 60 (Septon of Kuraray Co., Ltd. CJ103", "Septon CJ102", "Septon CJ002"), and the thickness of the covering part was set to three kinds of 1, 2, and 3 mm to manufacture the toothbrush samples of Examples 4-7 and Comparative Examples 5-8.

Embodiment 8

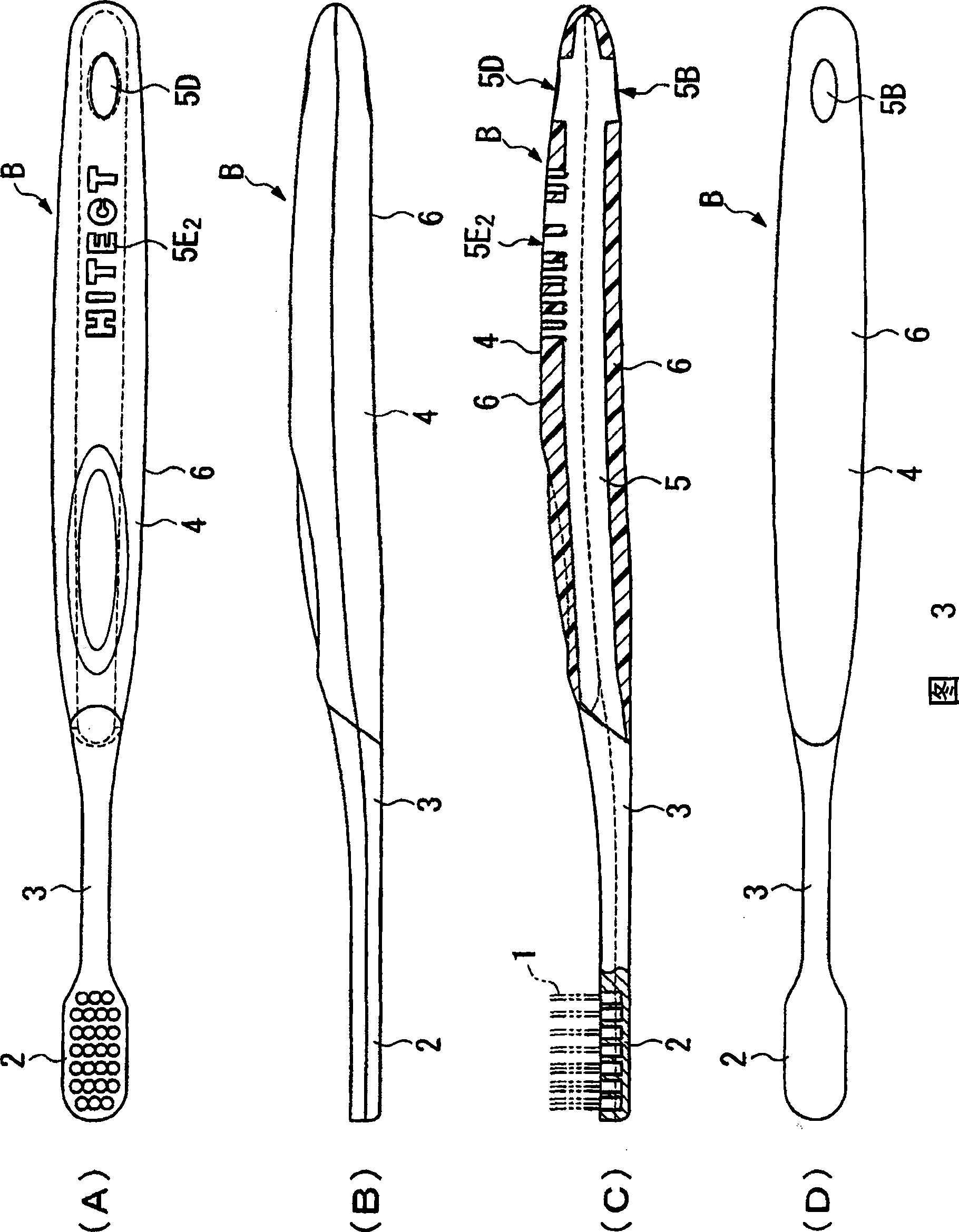

[0113] A styrene-based elastomer resin with a rubber hardness of 20 ("Thermolast" of KRAIBURG, Germany) was used as the covering material, and about 90% of the surface of the gripping part was covered with an average thickness of 3mm to form a covering with a coefficient of friction of 2. Overlay, make a toothbrush sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com