A compound bactericide for controlling plant powdery mildew

A technology for compounding fungicides and powdery mildew, applied in the field of pesticides, can solve problems such as drug resistance and effect decline, and achieve the effects of many sites, low cost, and high biological safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

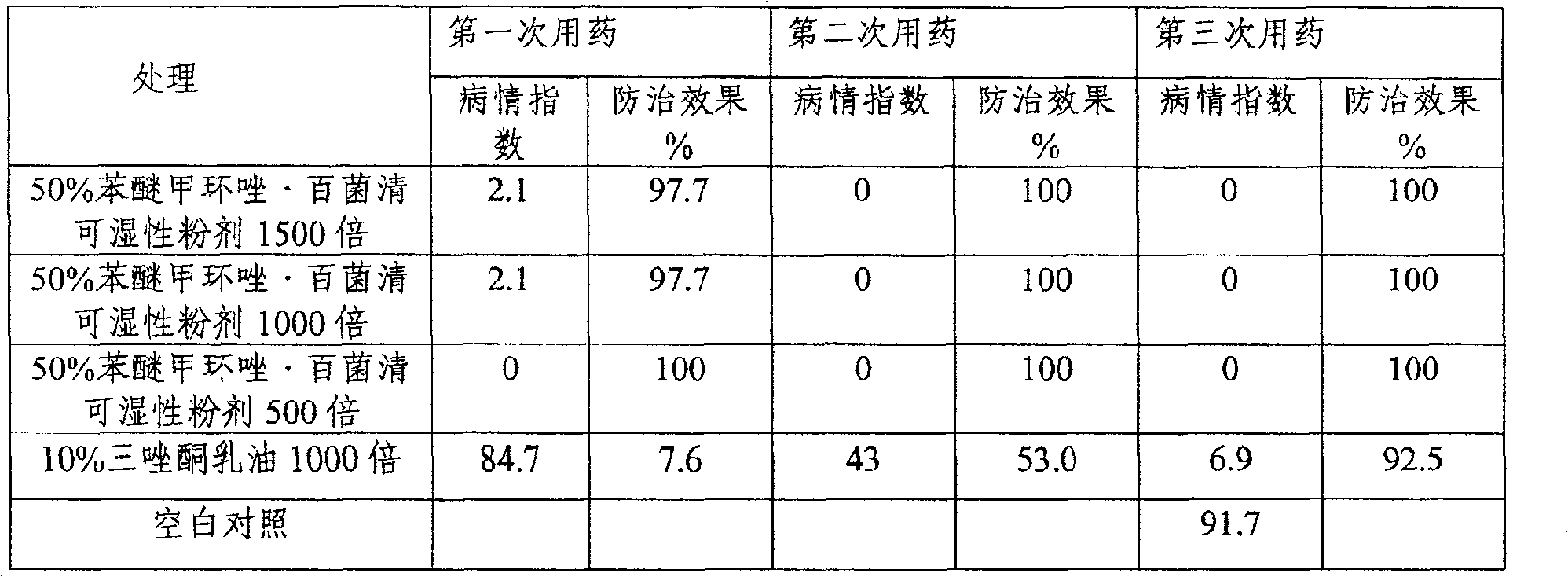

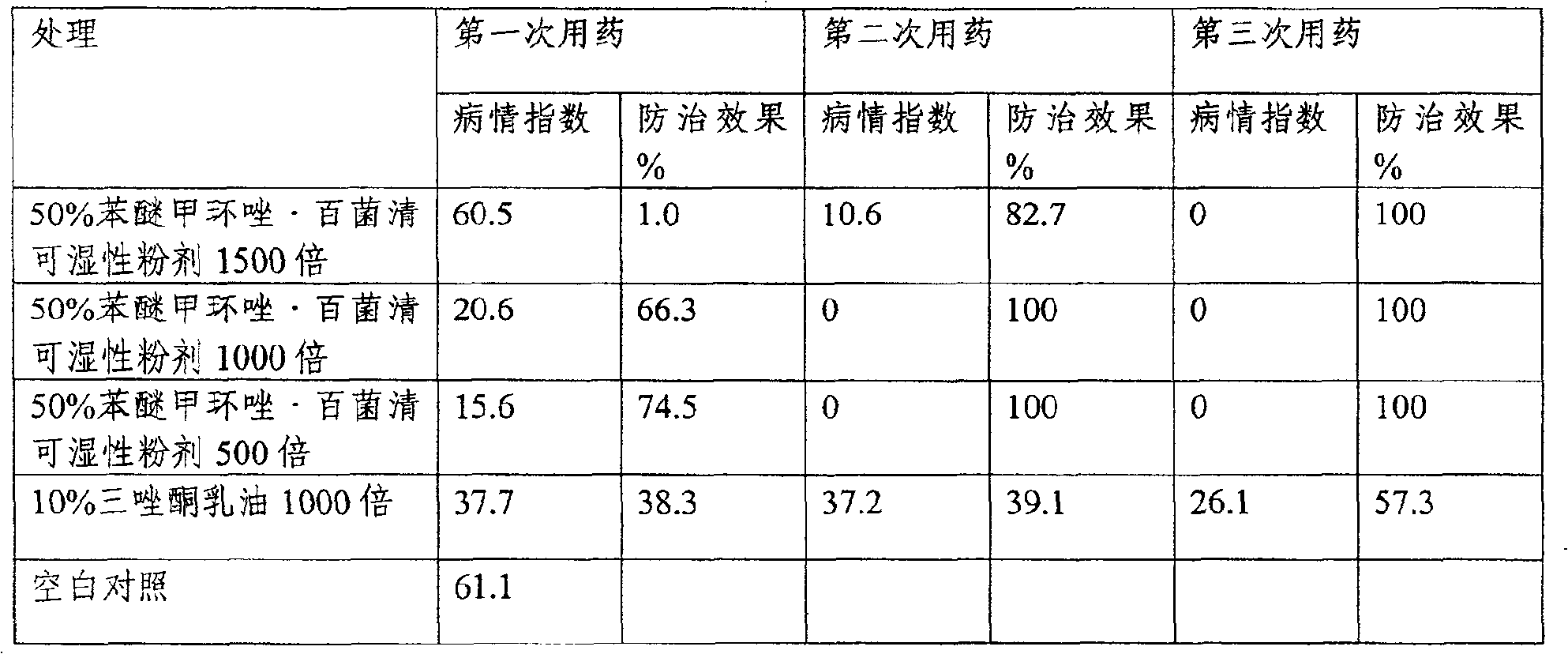

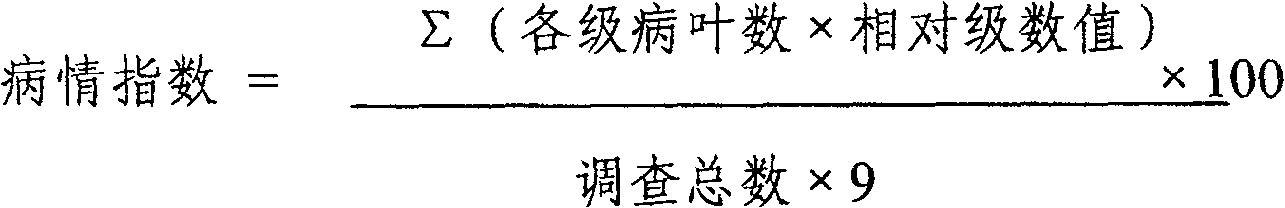

Examples

Embodiment 1

[0022] The preparation of embodiment 1 composite wettable powder

[0023] 50% difenoconazole · chlorothalonil (1:10) wettable powder: take 4.75 parts of 96% difenoconazole, 49.4 parts of 92% chlorothalonil, add 2 parts of sodium lignosulfonate, CMC 1.5 Parts, 5 parts of sodium dodecylbenzenesulfonate, 37.3 parts of light calcium. After mixing and stirring, enter the primary crushing (coarse grinding, the particle fineness reaches 50 mesh sieve); after further mixing and stirring, enter the secondary crushing (jet milling, particle fineness reaches 325 mesh sieve); package as a product.

Embodiment 2

[0024] The preparation of embodiment 2 composite wettable powder

[0025] 50% difenoconazole · chlorothalonil (1:4) wettable powder: take 10.42 parts of 96% difenoconazole, 43.48 parts of 92% chlorothalonil, add 2 parts of sodium lignosulfonate, CMC 1.5 Parts, 5 parts of sodium dodecylbenzenesulfonate, 37.6 parts of light calcium. After mixing and stirring, enter the primary crushing (particle fineness reaches 50 mesh sieve); after further mixing and stirring, enter the secondary crushing (particle fineness reaches 325 mesh sieve); pack as a product.

Embodiment 3

[0026] The preparation of embodiment 3 composite wettable powder

[0027] 50% difenoconazole · chlorothalonil (1:16) wettable powder: take 3.07 parts of 96% difenoconazole, 51.15 parts of 92% chlorothalonil, add 2 parts of sodium lignosulfonate, CMC 1.5 Parts, 5 parts of sodium dodecylbenzenesulfonate, 37.28 parts of light calcium. After mixing and stirring, enter the primary crushing (particle fineness reaches 50 mesh sieve); after further mixing and stirring, enter the secondary crushing (particle fineness reaches 325 mesh sieve); pack as a product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com