Closed square cell

A technology for square batteries and battery casings, which is applied to battery pack components, battery covers/end covers, battery boxes/coatings, etc., and can solve problems such as uneven working pressure of cracking bends and low reliability of cracking bends , to achieve the effect of stable working pressure, high crack resistance and reduced deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

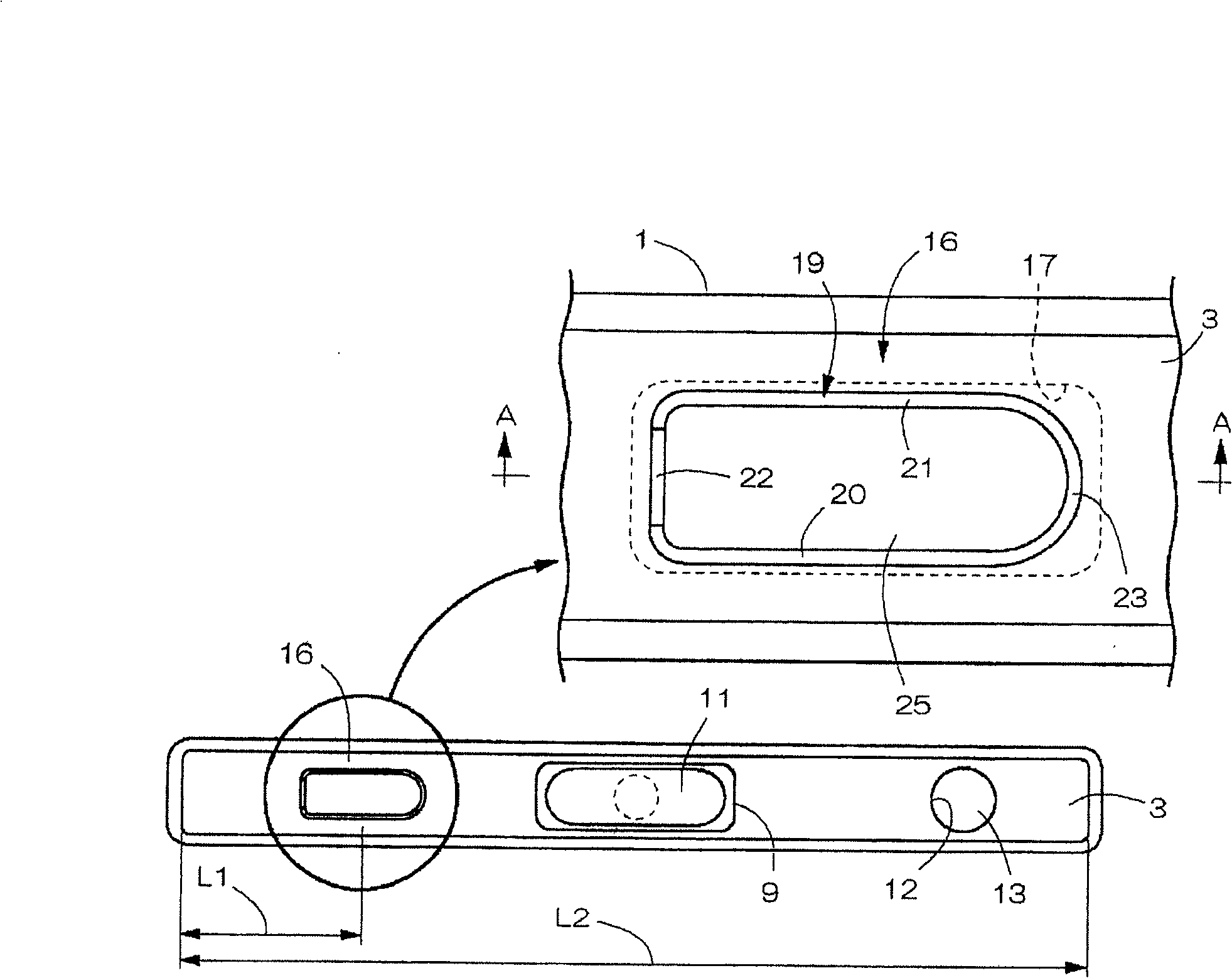

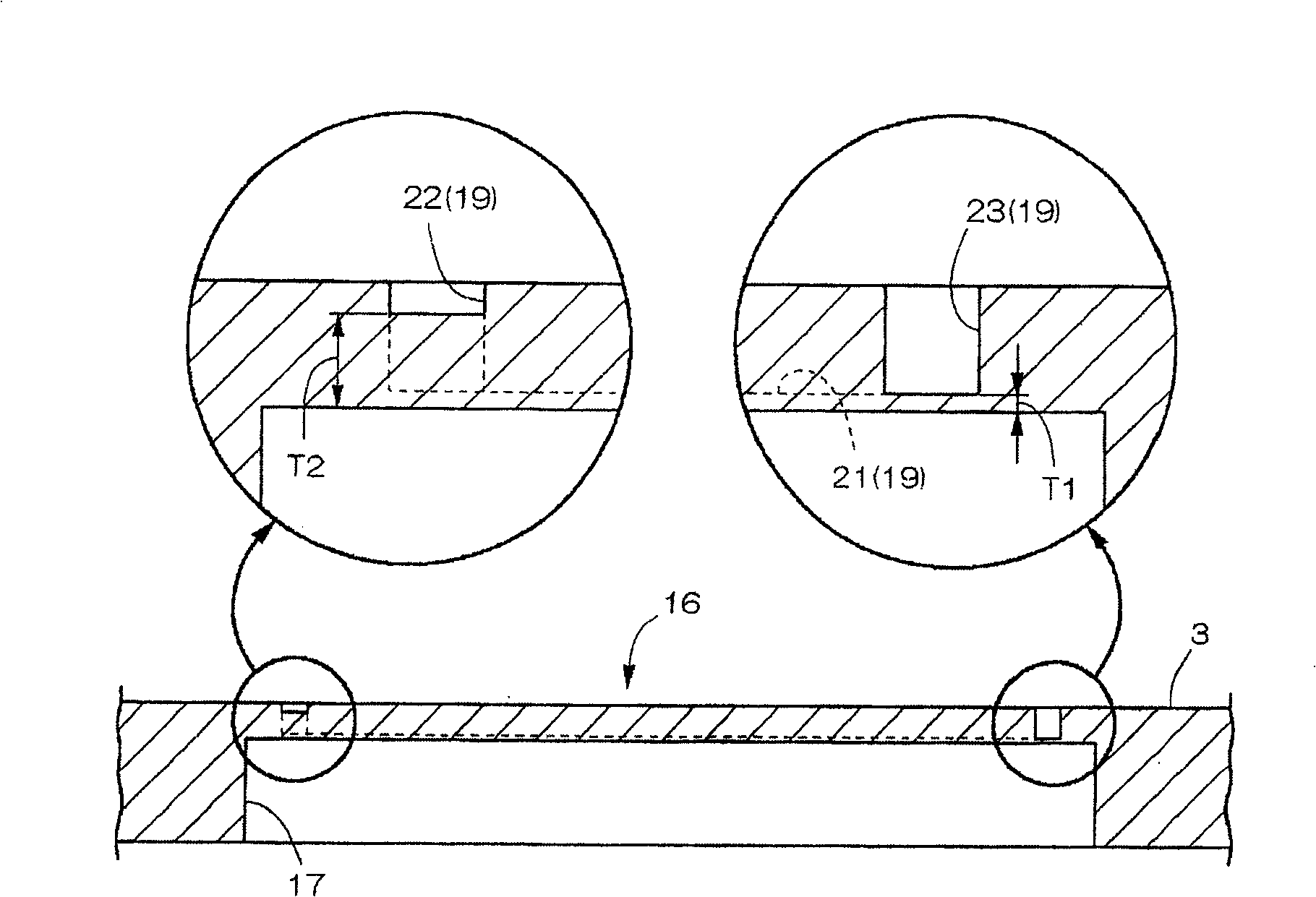

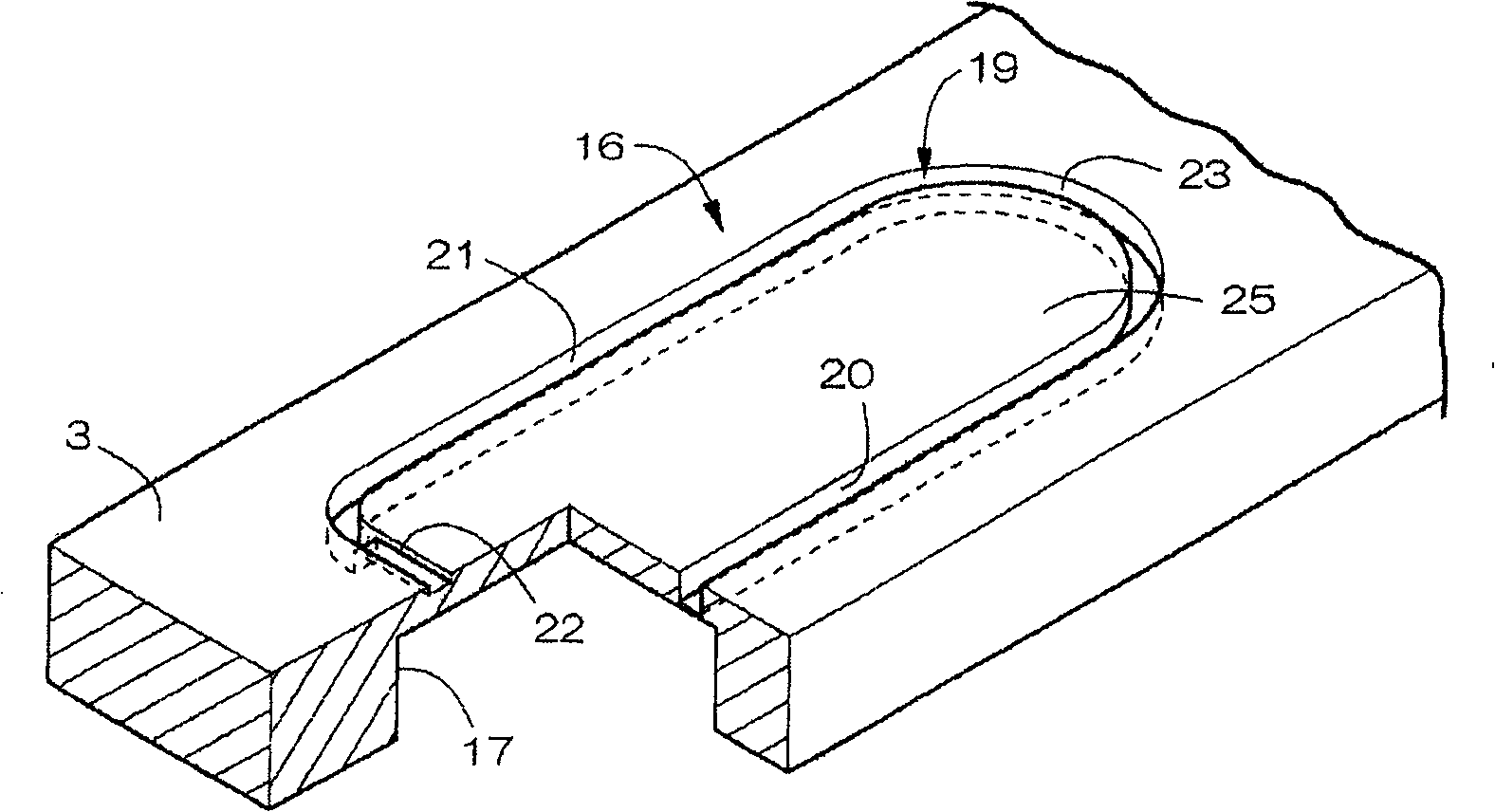

[0029] Figure 1 to Figure 4 Example 1 showing a lithium ion secondary battery as a sealed prismatic battery of the present invention, such as Figure 4 As shown, it is equipped with: a bottomed square battery case 1 with long left and right lateral openings on the top, an electrode body 2 and a non-aqueous electrolyte contained in the battery case 1, and the top of the opening of the battery case 1 is closed. The horizontally long cover 3, the plastic insulator 5 disposed inside the cover 3, and the like. The battery case 1 is formed by deep-drawing a plate made of aluminum or aluminum alloy to make a thin piece with vertically long top and bottom.

[0030] In the electrode body 2 , a separator made of a polyethylene microporous film is interposed between a sheet-shaped positive electrode and a negative electrode and wound in a spiral shape. A thin plate-shaped positive electrode current collector lead 6 made of aluminum or an aluminum alloy is drawn upward from the positiv...

Embodiment 2

[0043] In Example 2, each bottom wall thickness T1 of the grooves 20 , 21 , and 23 other than the end side groove 22 of the cleavage bend 16 is set to 0.031 mm. Since the other points are the same as those in Embodiment 1, description thereof will be omitted.

Embodiment 3

[0045] In Example 3, the front and rear thickness of the battery is increased to 4.0 mm, and correspondingly, the front and rear width of the cracking bend 16 is also increased to 2.5 mm. The respective bottom wall thickness dimensions T1 of the groove portions 20 , 21 , and 23 other than the end side groove portion 22 are set to 0.035 mm, respectively. Other points are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com