Liquid bearing pier structure

A liquid and bridge pier technology, applied in infrastructure engineering, bridges, bridge parts, etc., can solve the problems of complex construction, can not directly reflect the load effect, consume a lot of manpower and material resources, and achieve the guarantee of construction quality, convenient factory processing, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

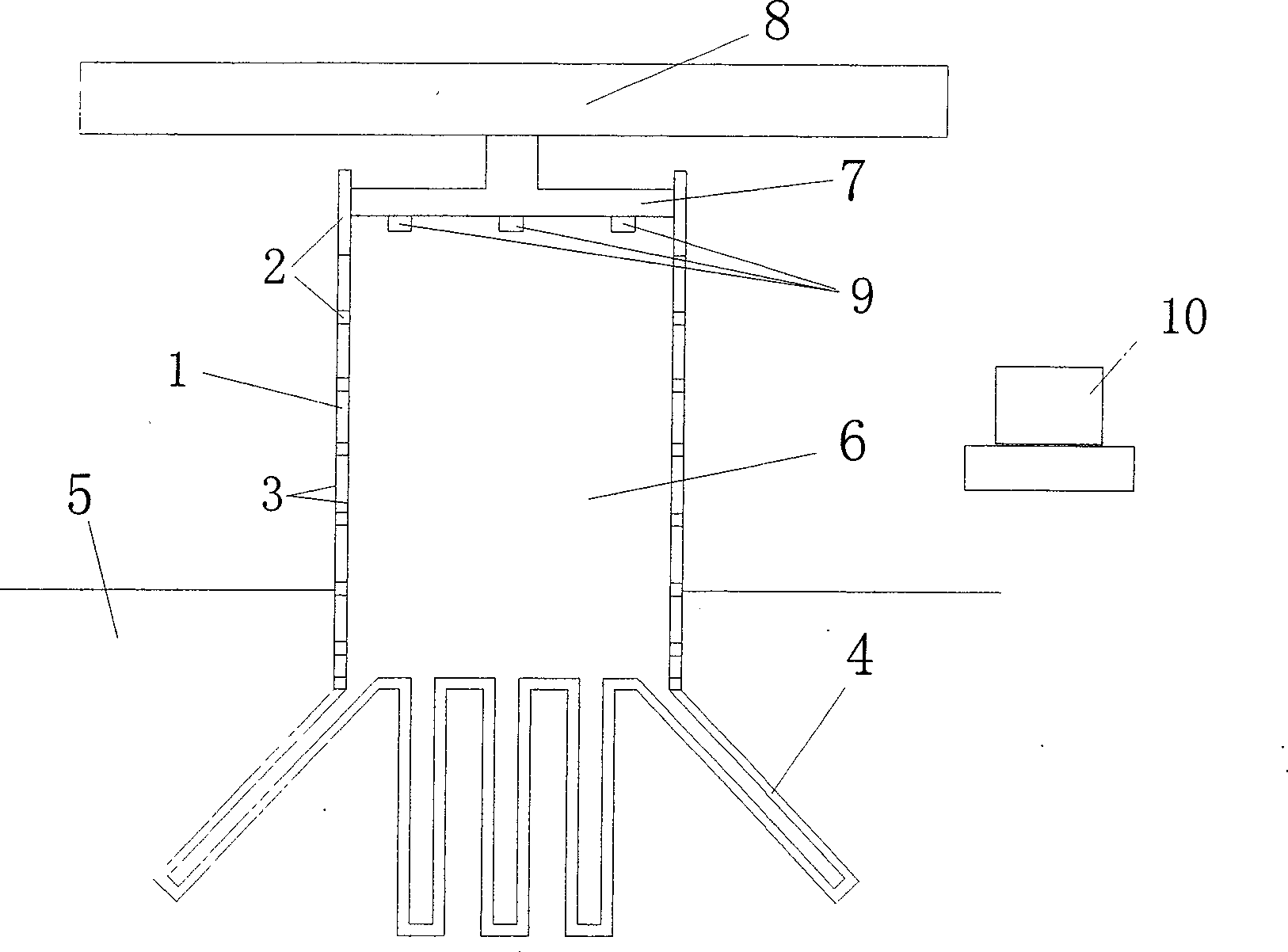

[0020] According to the designed shape and size of the pier, the frame 2 of the enclosure structure 1 is made of metal materials, and then covered with a membrane 3 with waterproof capability and certain tensile capacity to form a complete enclosure structure 1 .

[0021] Also use the metal frame to add film to make the foundation 4 that is root-like divergence. The foundation 4 is embedded in the soil body 5 .

[0022] The foundation 4 can also be formed by pouring conventional reinforced concrete materials.

[0023] A liquid 6 is then injected into the interior of the envelope 1 .

[0024] Inside the envelope 1 , on top of the liquid 6 , a support 7 is mounted. The upper surface of the support 7 is connected with the upper structure 8 of the bridge, and the lower surface is in close contact with the liquid 6 and seals the liquid 6 within the enclosure structure 1 . A pressure sensor 9 capable of real-time monitoring of the pressure data of the liquid 6 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com