Method for computing uniformly-mixing efficiency in oiron ore powder uniformly-mixing operation

A calculation method and technology for iron ore powder, applied in the calculation field of mixing efficiency, can solve the problems of non-use, increase in numerical value, and far from the gap, and achieve the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The mixed raw materials in this embodiment are South African powder, Australian powder, Brazilian powder, Iranian powder, Brazilian fine powder, Russian fine powder, Peru fine powder, Meishan fine powder, Yeshan self-melting powder, New Zealand fine powder, Yangdi fine powder , Boron fine powder, iron oxide scale, gas ash, steel slag, sintering return ore, dolomite powder.

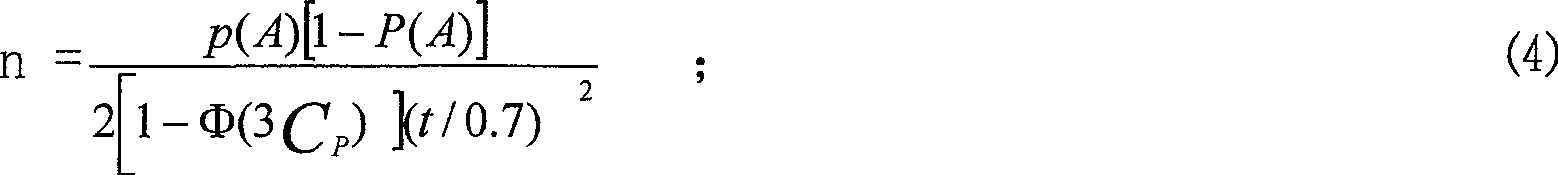

[0082] Tfe can be obtained by on-site testing, P (A) is calculated by P (A)=(10 / 7)Tfe, and the Tfe=60.7% measured in this embodiment, P(A)=(10 / 7)Tfe=86.71%.

[0083] Cp represents the degree to which the processing capacity of the mixing operation meets the technical requirements. Check the standard normal distribution function value table, 3Cp=1.81, Cp=0.6033.

[0084] t represents the technical requirement for the mixing operation, and t=0.008 in this embodiment.

[0085] n = p ( A ...

Embodiment 2

[0091] The mixed raw materials in this embodiment are South African powder, Australian powder, Brazilian powder, Iranian powder, Brazilian fine powder, Russian fine powder, Peru fine powder, Meishan fine powder, Yeshan self-melting powder, New Zealand fine powder, Yangdi fine powder , Boron fine powder, iron oxide scale, gas ash, steel slag, sintering return ore, dolomite powder.

[0092] Tfe can be obtained by on-site testing, and P(A) is calculated by P(A)=(10 / 7)Tfe, and the measured Tfe=60.4% in this embodiment, P(A)=(10 / 7)Tfe=86.71%.

[0093] Cp represents the degree to which the processing capacity of the mixing operation meets the technical requirements. It is obtained from the standard normal distribution function value table, 3Cp=1.15, Cp=0.3833.

[0094] t represents the technical requirement for the mixing operation, and t=0.008 in this embodiment.

[0095] n = p ( ...

Embodiment 3

[0101] The mixed raw materials in this embodiment are South African powder, Australian powder, Brazilian powder, Iranian powder, Brazilian fine powder, Russian fine powder, Peru fine powder, Meishan fine powder, Yeshan self-melting powder, New Zealand fine powder, Yangdi fine powder , Boron fine powder, iron oxide scale, gas ash, steel slag, sintering return ore, dolomite powder.

[0102] Tfe can be obtained by on-site testing, and P (A) is calculated by P (A)=(10 / 7)Tfe, and the Tfe=60.1% measured in this embodiment, P(A)=(10 / 7)Tfe=85.86%.

[0103] Cp represents the degree to which the processing capacity of the mixing operation meets the technical requirements. It is obtained from the standard normal distribution function value table, 3Cp=1.75, Cp=0.5833.

[0104] t represents the technical requirement for the mixing operation, and t=0.008 in this embodiment.

[0105] n = p ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com