Seamless split joint video frequency wall

A seamless splicing and video wall technology, which is applied in the direction of identification devices, optical fiber bundles, instruments, etc., can solve the problem of inconsistency, and achieve the effect of simple manufacturing, ensuring continuity and integrity, and eliminating physical splicing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

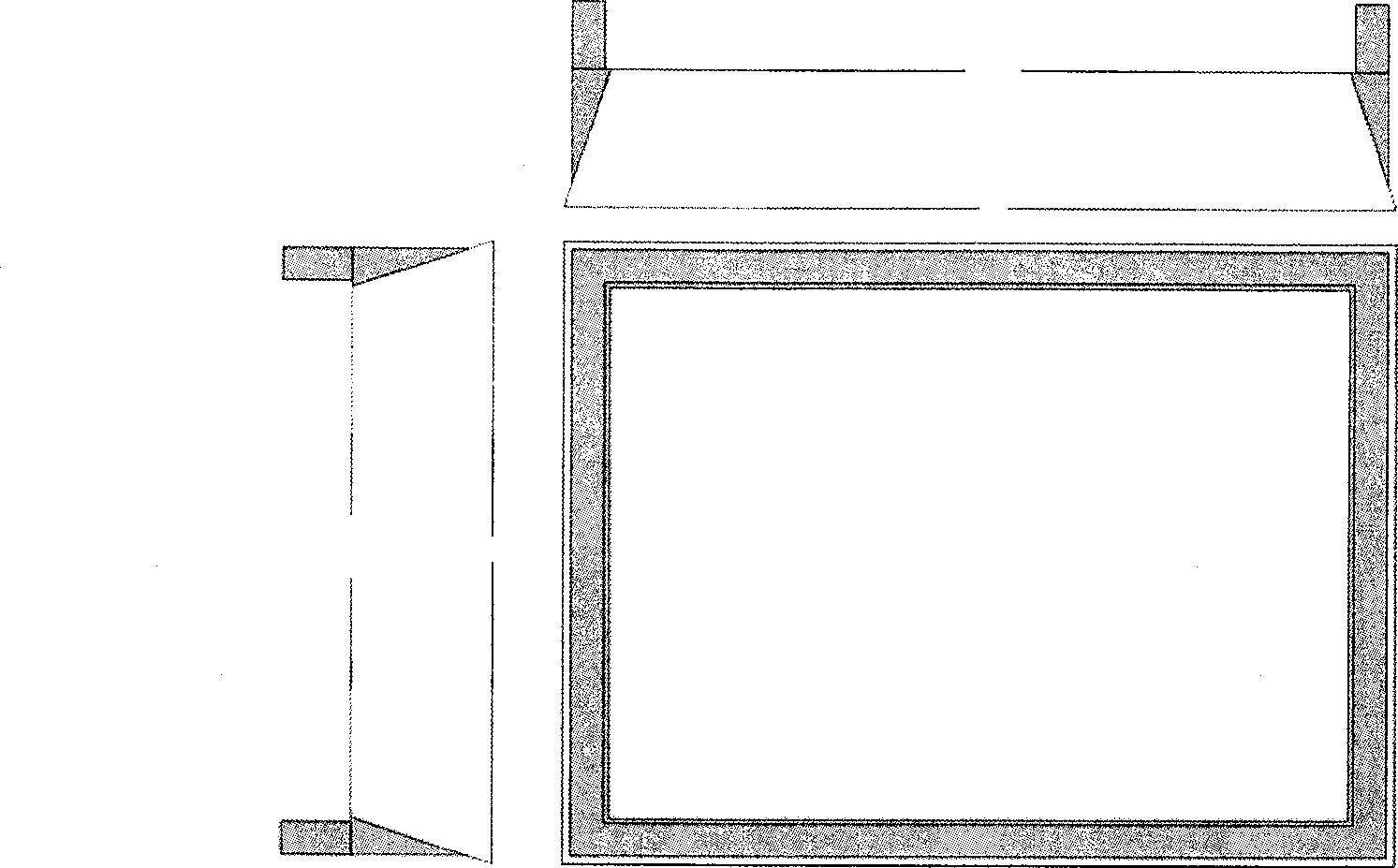

[0018] figure 1 : The screen frame is customized according to the structure of the mold, the mold is spliced into a frame according to the size of the screen, the screen is embedded in the frame, and all the ladders around the screen except 0.1 to 5 mm behind the imaging surface of the screen are embedded in the connecting fixed frame. The part of the screen exposed from the frame is 0.1-5 mm, depending on the size of the screen, the smaller the screen, the smaller the exposed part, and the plane of the exposed part of the screen is slightly larger than the frame border by 0.05-2 mm, so that it can be seamlessly spliced with the screen.

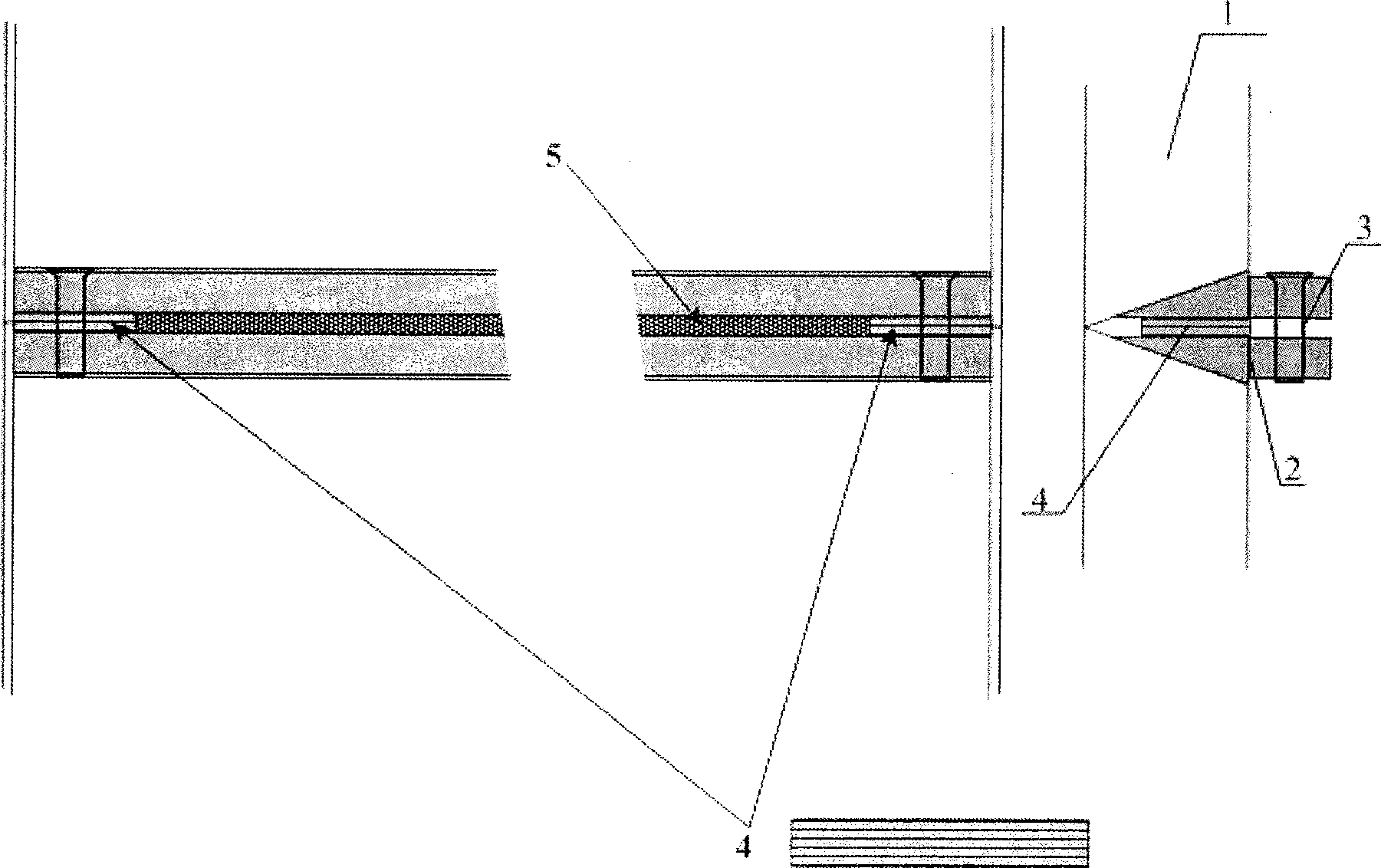

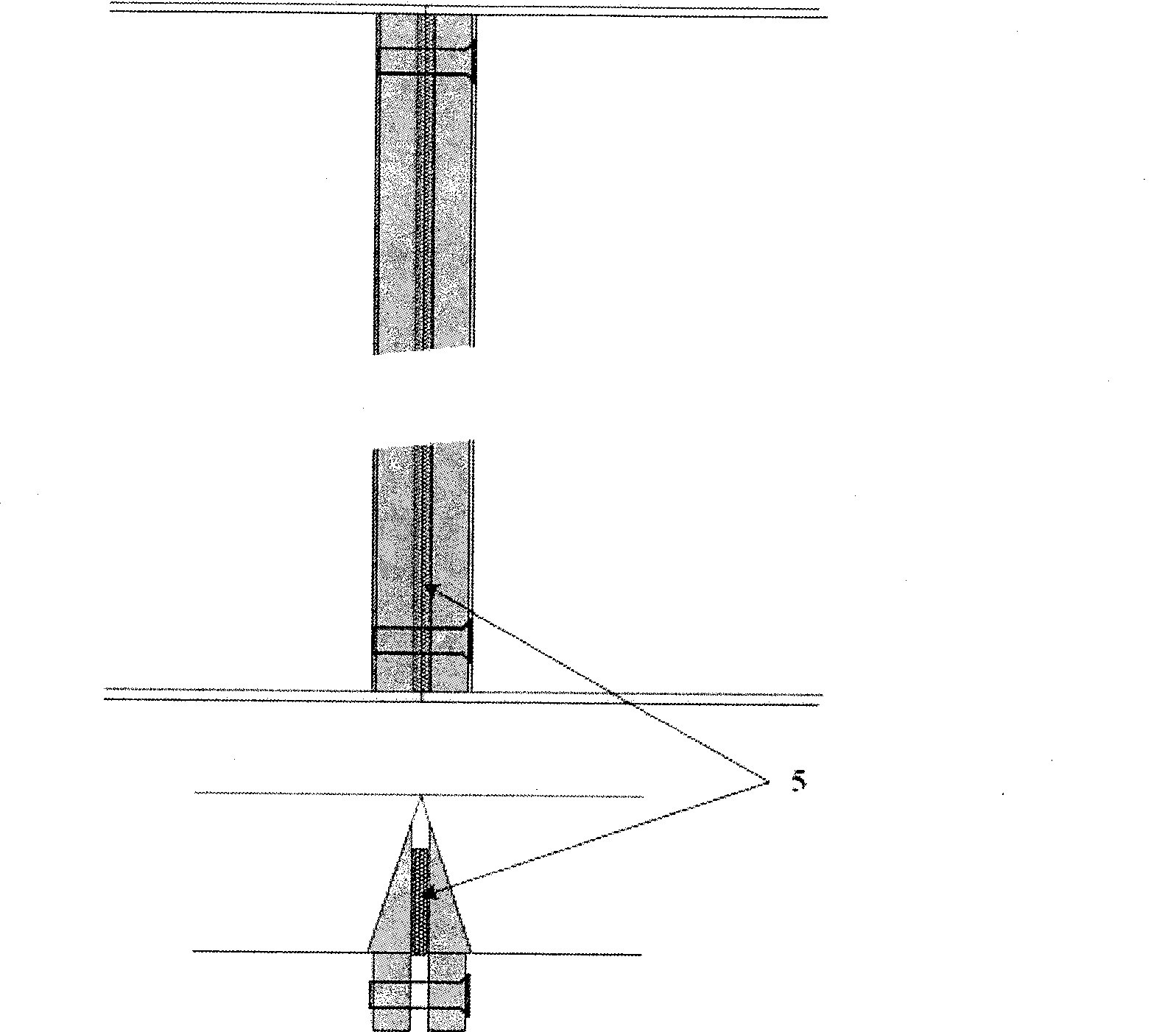

[0019] figure 2 , image 3 : One is horizontal splicing and the other is vertical splicing. The specific implementation method has been the same. There are positioning screw holes on the rear frame of the screen frame, which are used for the positioning and fixing connection between the screens. The adjacent screen frames are connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com