Field emission flat panel display with shield electrode structure and its producing method

A flat-panel display and shielding electrode technology, which is applied in the field of field emission flat-panel displays with a shielding electrode structure and its manufacturing process, can solve the problems of unfavorable flat-panel devices and burnt-out of the overall device, so as to increase the success rate, improve the success rate, Create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

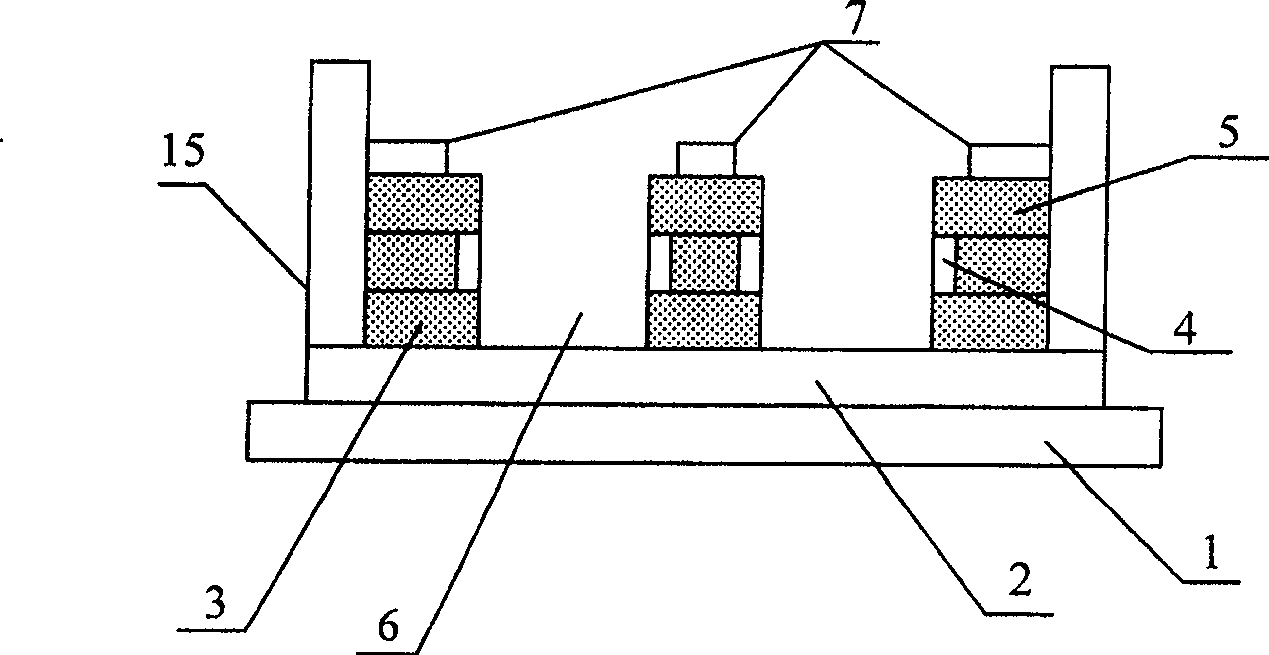

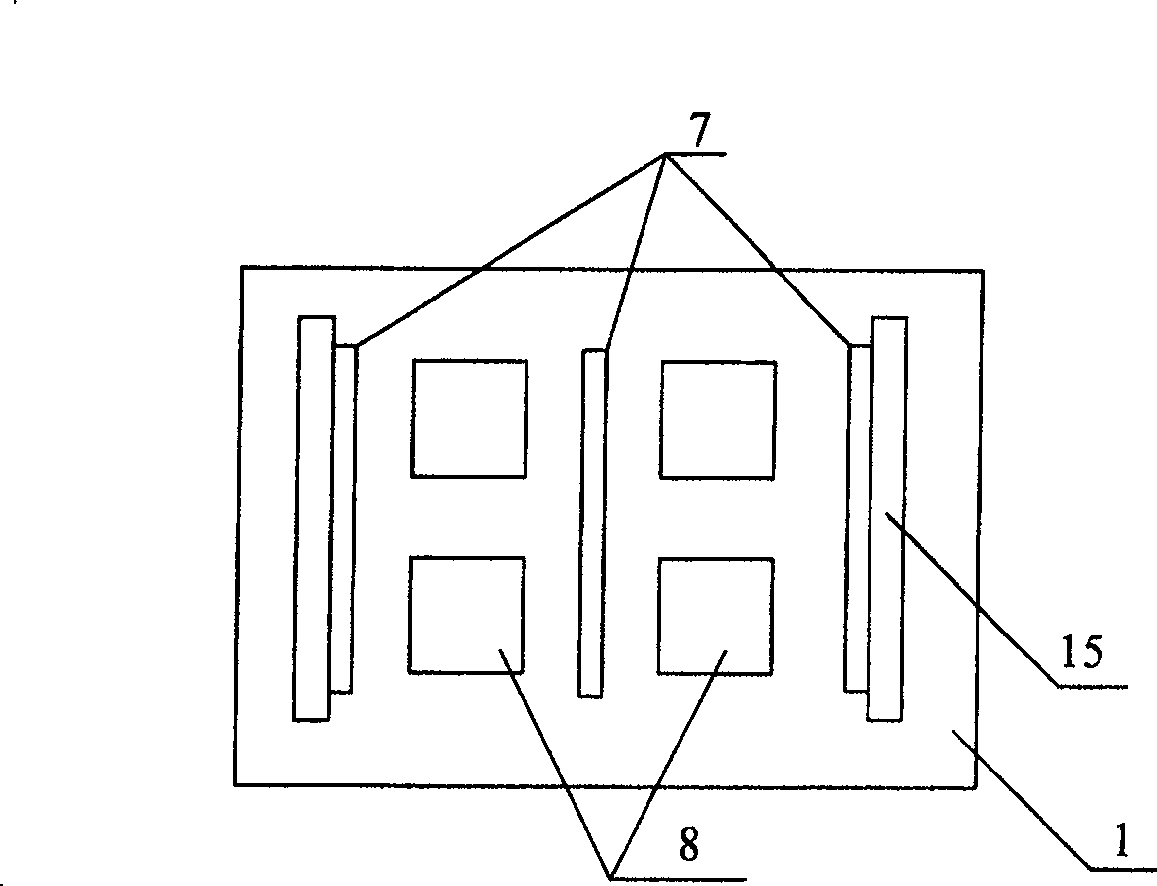

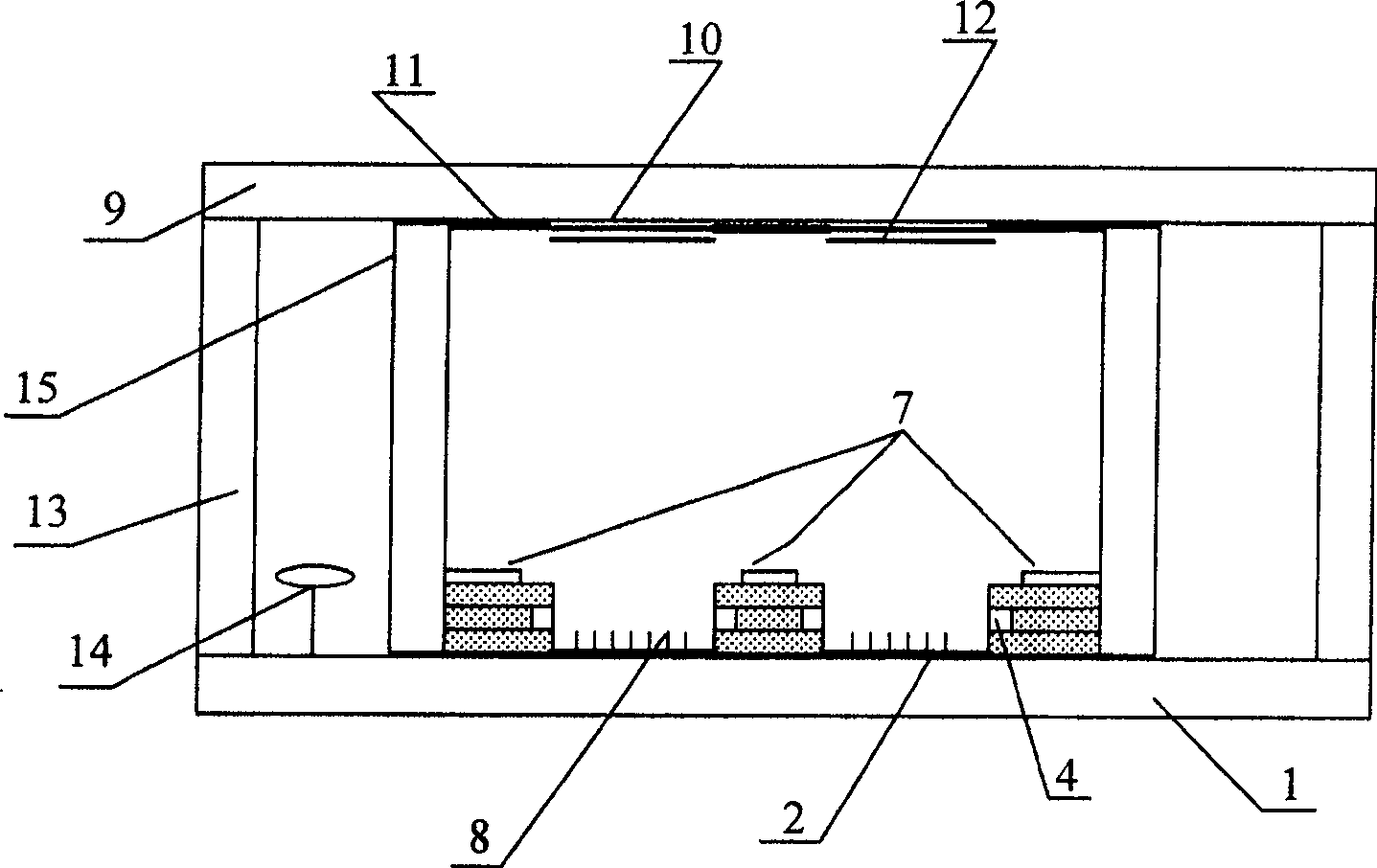

[0044] The present invention comprises a sealed vacuum chamber composed of a cathode panel 1, an anode panel 9 and surrounding glass enclosures 13, a printed carbon nanotube cathode 8 on the cathode panel 1, and a control grid for controlling the electron emission of the carbon nanotube cathode 8 Pole 4, supporting wall structure 15, tin indium oxide film layer 10 photoetched on the anode panel 9 and phosphor powder 12 layers prepared on the tin indium oxide film layer 10, characterized in that: the vacuum chamber inside the display There is a shielding electrode structure 7 for shielding secondary electron emission.

[0045] The shielding electrode structure 7 includes a base material 1, a cathode conductive strip 2 arranged on the base material, an insulating isolation layer 3 arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com