Device for cooling an electrical component and production method thereof

A self-generated technology for electrical components, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as poor thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

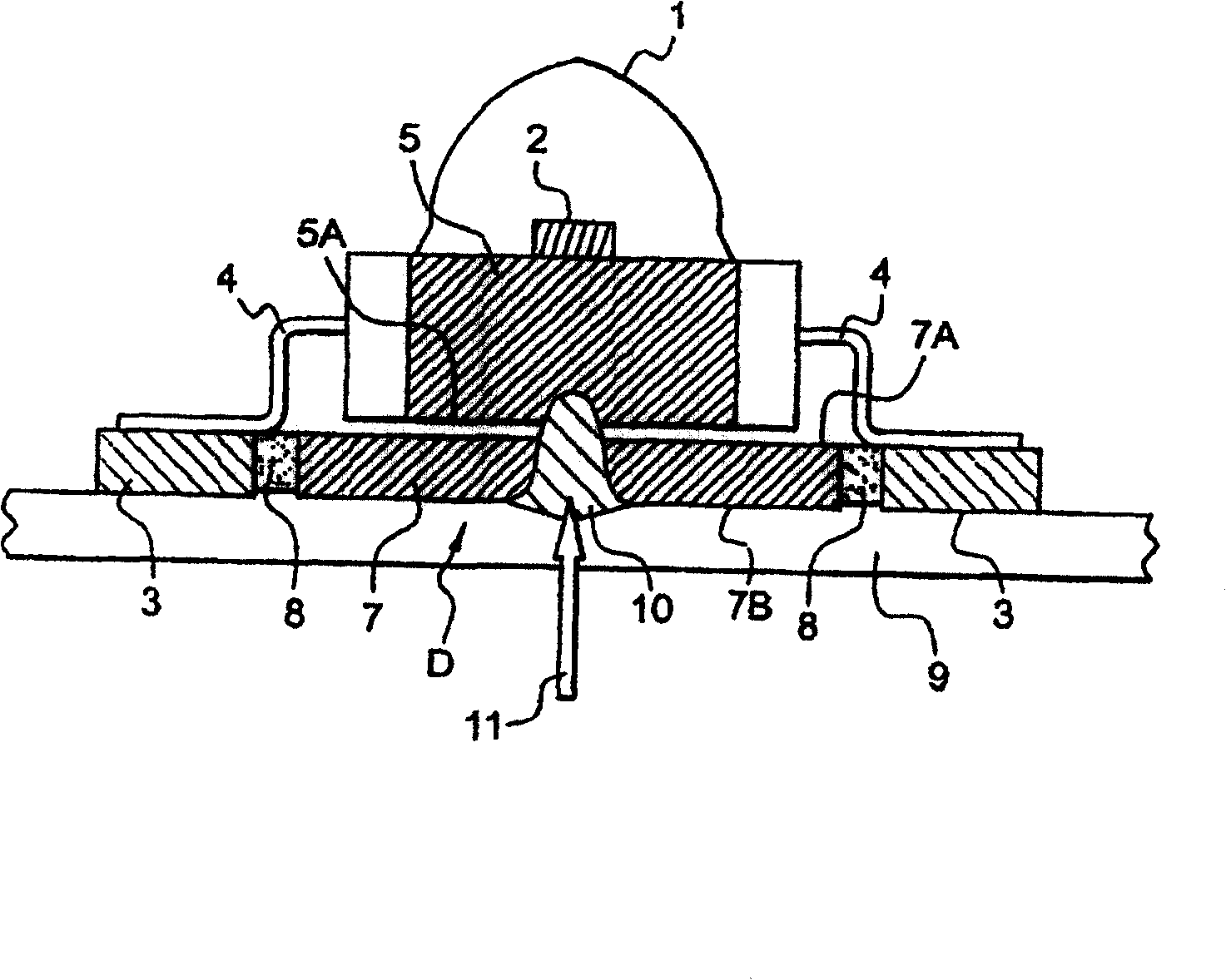

[0027] The light-emitting diode 1 includes a heat source, namely a semiconductor 2 . The light-emitting diodes 1 are to be cooled by means of a cooling device designated according to the invention with the reference symbol D. FIG.

[0028] The light-emitting diode 1 is provided with a conductive terminal 4 to connect it to two completely parallel conductive strips 3, so as to provide the light-emitting diode 1 with necessary electric energy for operation. The conductive lug 4 also mechanically fixes the LED 1 to the conductive strip 3 .

[0029] The semiconductor 2 is supported by a heat dissipation metal block 5 . The heat sink 5 has a surface 5A through which heat is preferably removed.

[0030] The device D comprises a metal plate forming a heat sink 7 having a large surface 7A relative to the surface 5A. The heat sink 7 comprises two opposite small surfaces which are connected to the busbar 3 by overmolding material 8 , preferably plastic, so that the heat sink 7 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com