Centrifugal pump cover

A centrifugal pump and pump cover technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of insufficient strength, short service life, simple structure, etc., and achieve the effect of enhancing overall strength and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

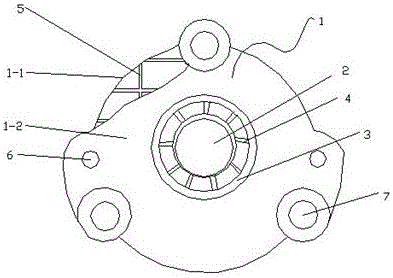

[0014] Such as figure 1 As shown, as the first embodiment of the present invention, a pump cover of a centrifugal pump includes a pump cover main body 1, and the center of the pump cover main body 1 has a shaft hole 2 for pump shaft installation, and the shaft hole 2 The outer circumference of the shaft hole seat 3, the shaft hole 2 and the shaft hole seat 3 are coaxially arranged, and the outer side of the shaft hole 2 is divergently provided with a plurality of reinforcement ribs 4, and one end of the reinforcement rib 4 is connected to the shaft The outer edge of the hole 2, the other end is connected to the corresponding position of the shaft hole seat 3, the pump cover main body 1 is provided with a mounting hole 6 and a through hole 7, and the pump cover main body 1 includes an inner layer of the pump cover coaxially sleeved 1-1 and the outer layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com