Connecting module for tool rod and its tool handle

A technology for connecting components and tool rods, which is applied in the connection of rods, connecting components, threaded connections, etc., can solve the problems of inability to achieve universal interchange, poor sealing effect, and high manufacturing costs, and achieve fast disassembly and assembly. Good, low-cost manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

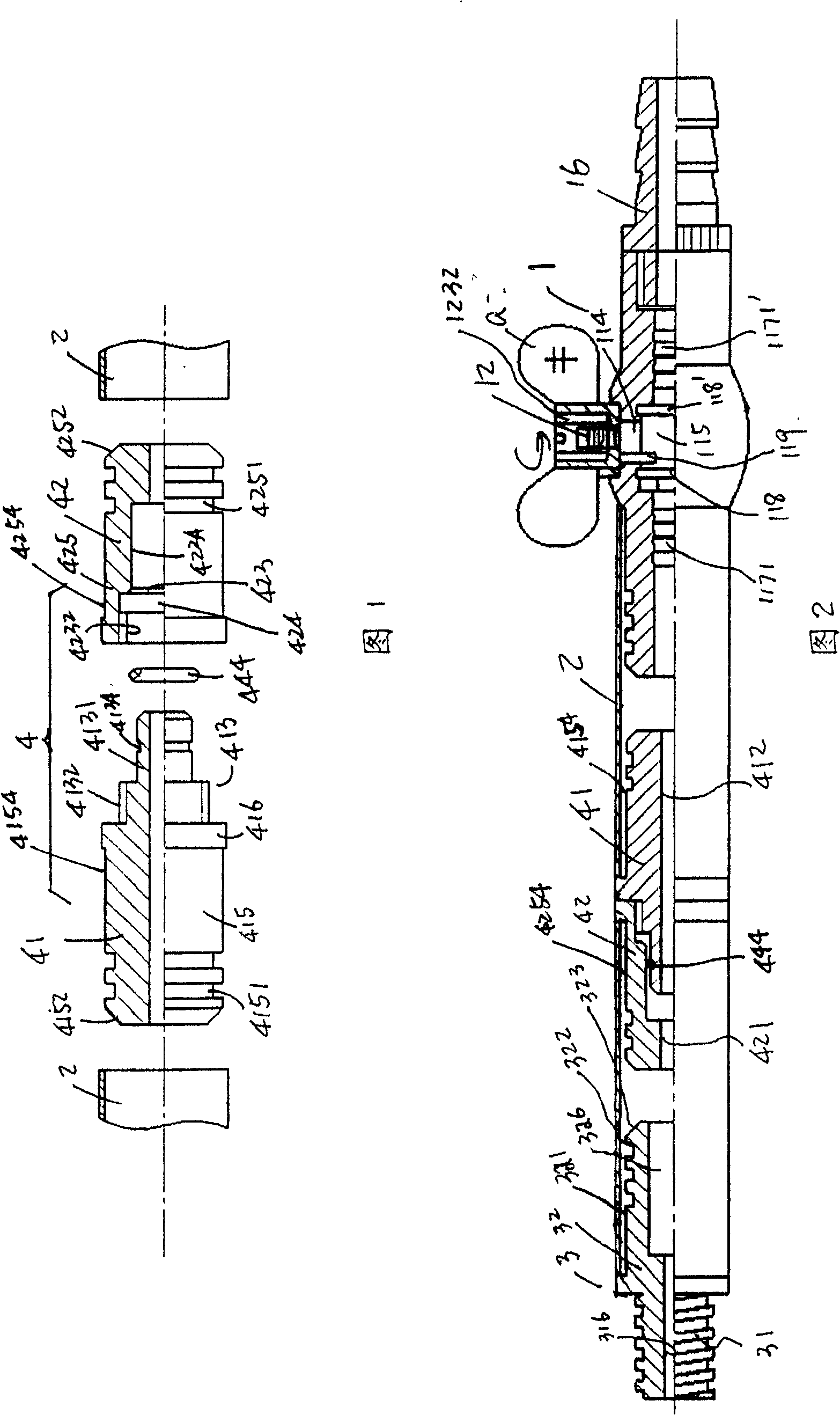

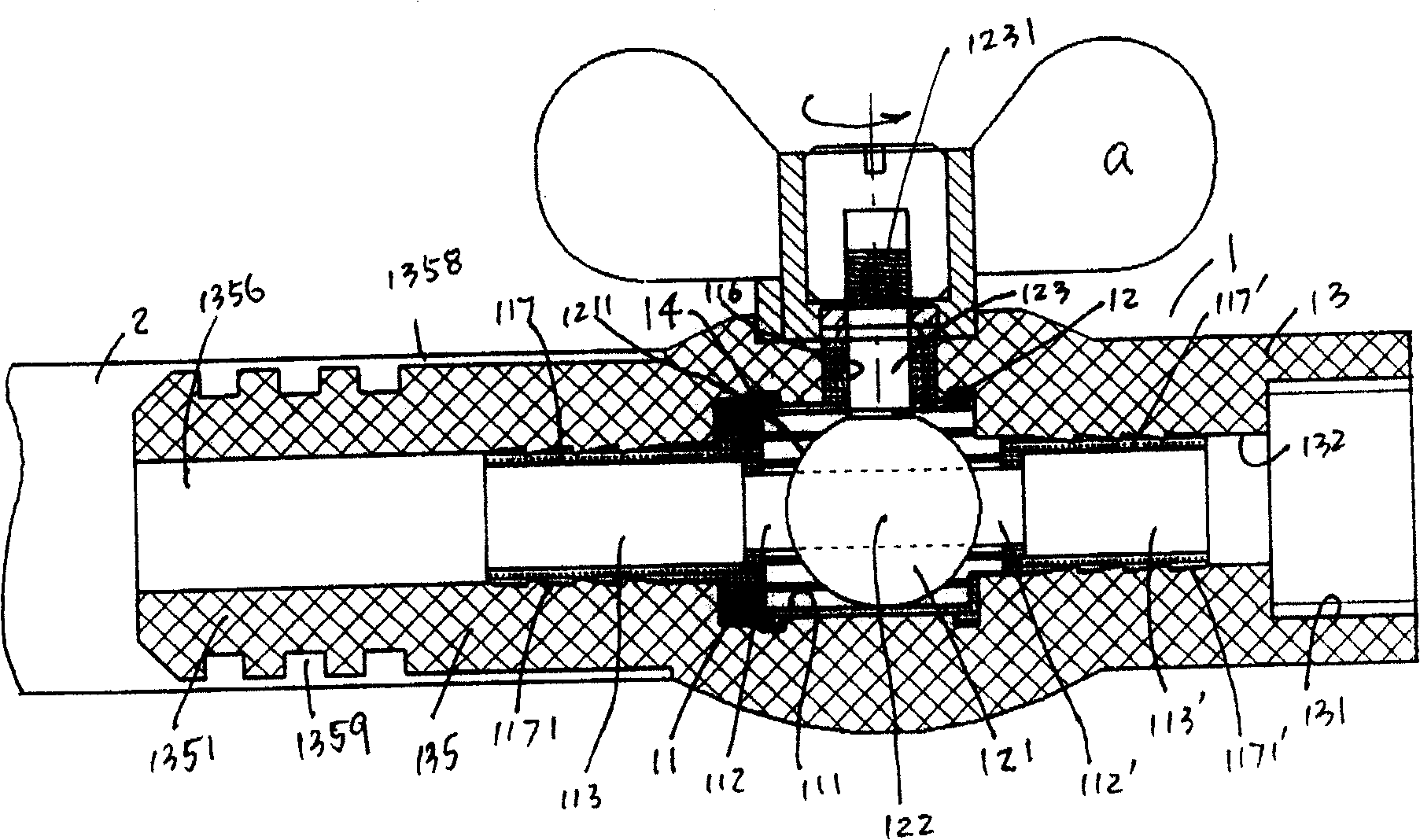

[0030] Please refer to Figs. 1-3, a tool bar connection assembly 4 includes a connecting sub-piece 41 fixed to a tool bar, and a connecting female part 42 fixed to another tool bar. The master part is combined with the sub-master part screw structure to realize the connection between the tool bars. One end of the connecting sub-piece 41 is provided with a sub-piece connecting rod section 415 connected with the tool bar 2. The outer part of the sub-piece connecting rod section is The diameter is slightly smaller than the outer diameter of the tool rod to form the colloid for bonding the tool rod to evenly surround ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com