Conductor coupler for high-voltage switch cabinet

A high-voltage switchgear and connector technology, applied in the electrical field, can solve the problems of inconvenient connection between main busbar and branch busbar, inability to use large-capacity switchgear, and difficulty in connecting circular busbars, etc., to achieve convenient connection and save space , the effect of reasonable electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

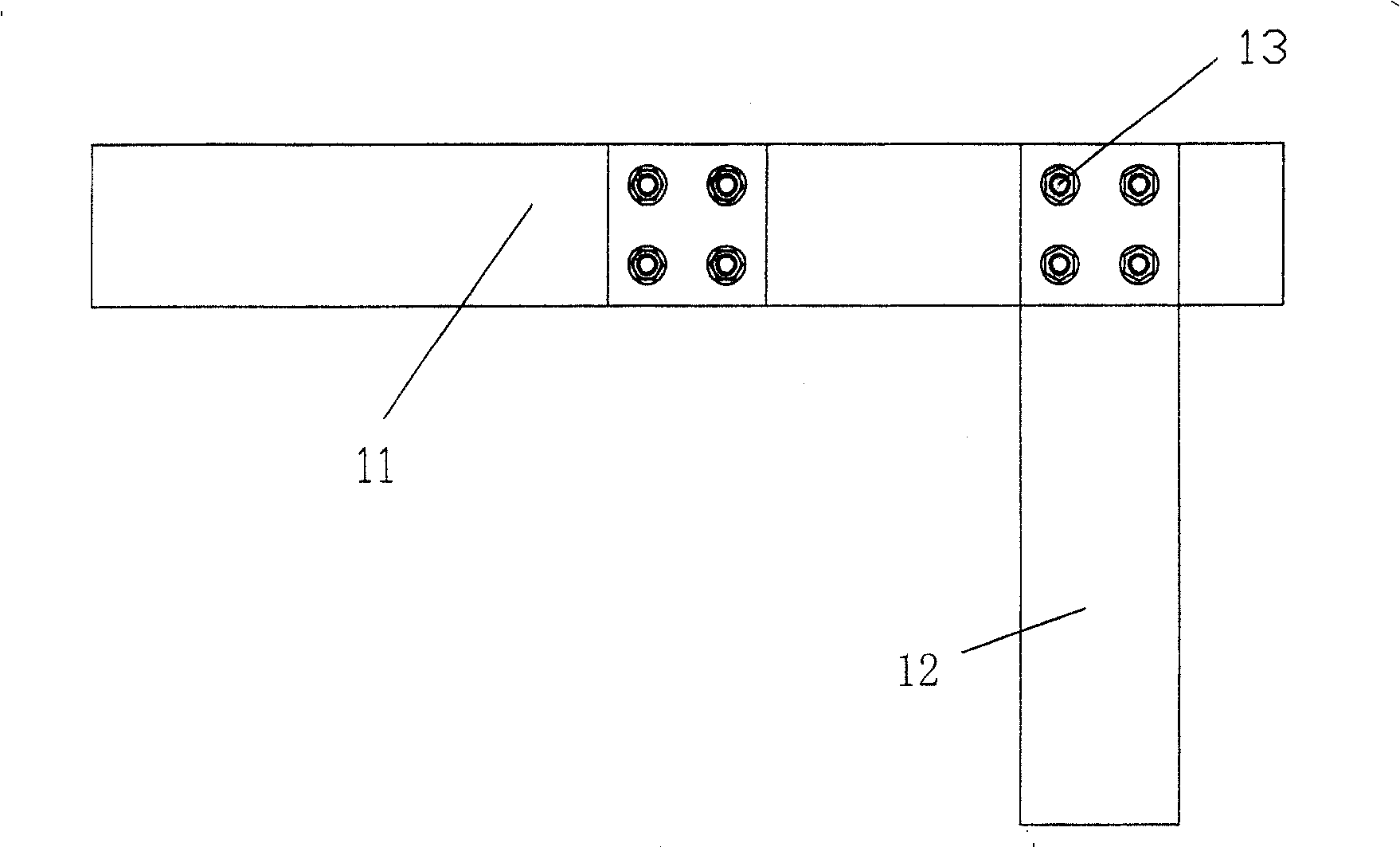

[0016] see figure 1 . The switchgear of the prior art adopts the rectangular busbar as shown in the figure, wherein 11 is a horizontal busbar, 12 is a branch busbar, both of which are rectangular, connected together with screws 13, which can ensure the connection strength and contact area of the busbar.

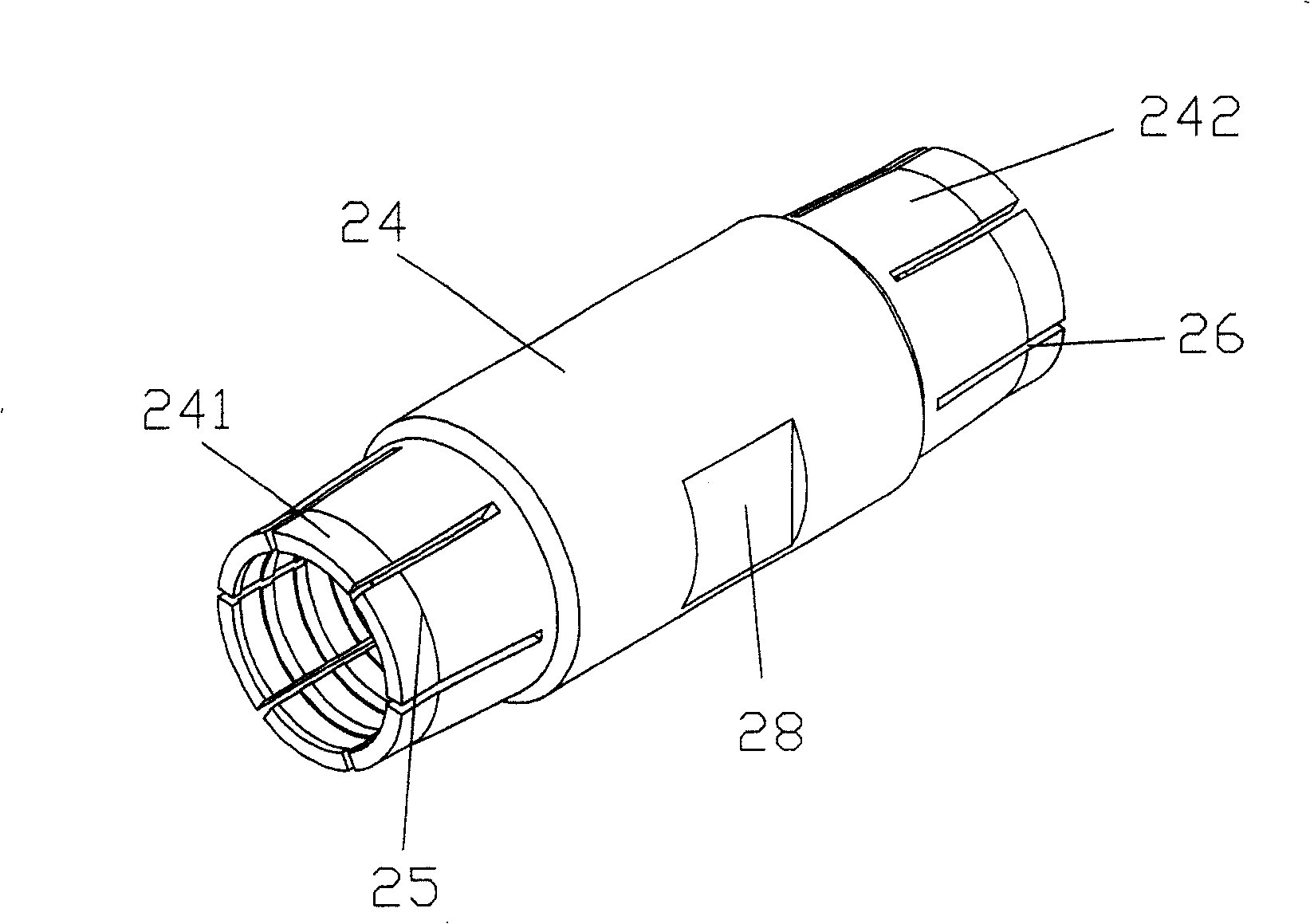

[0017] see figure 2 . The cross-section of the busbar 21 used in the present invention is circular, and the two sections of busbars are connected by a conductive coupler 24, and the two sections of busbars are respectively inserted into the two coupling ends of the coupler and are in close contact with the coupler; There is a compression nut 23 on the outside of each end to compress the connecting end and the busbar; there is also a locking nut 22 at the outer end of the compression nut to prevent the compression nut from coming out.

[0018] see image 3 , Figure 4 . The connector 24 of this embodiment is a straight-through type, with two connecting ends 241, 242, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com