Drawing work supplement method and drawing mould

A technology for drawing dies and process supplements, applied in the field of drawing dies, can solve problems such as cracked parts rigidity, parts wrinkle, lack, etc., to achieve the effects of increasing deformation, eliminating wrinkles, and suppressing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principle of the present invention will be described below based on some examples.

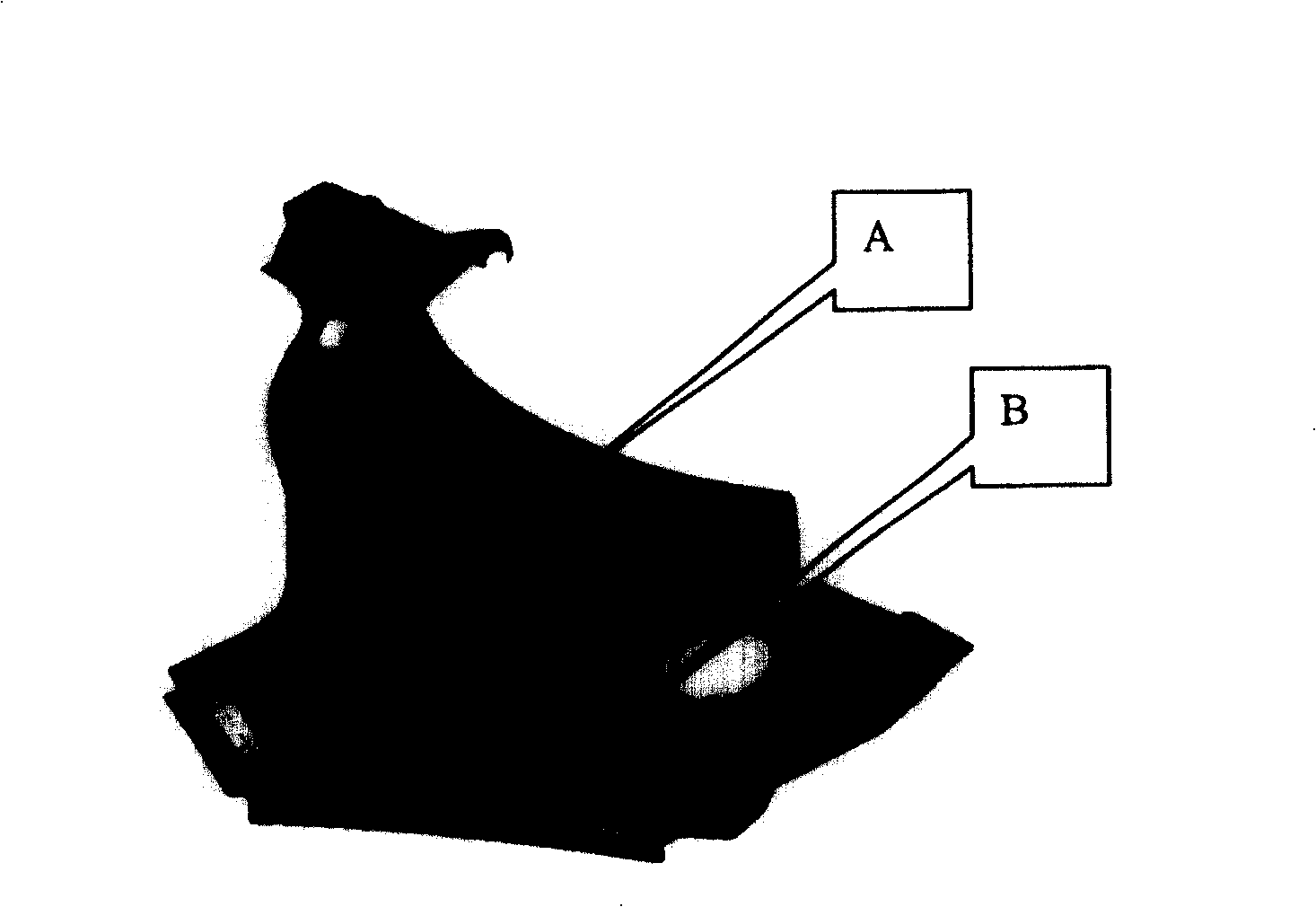

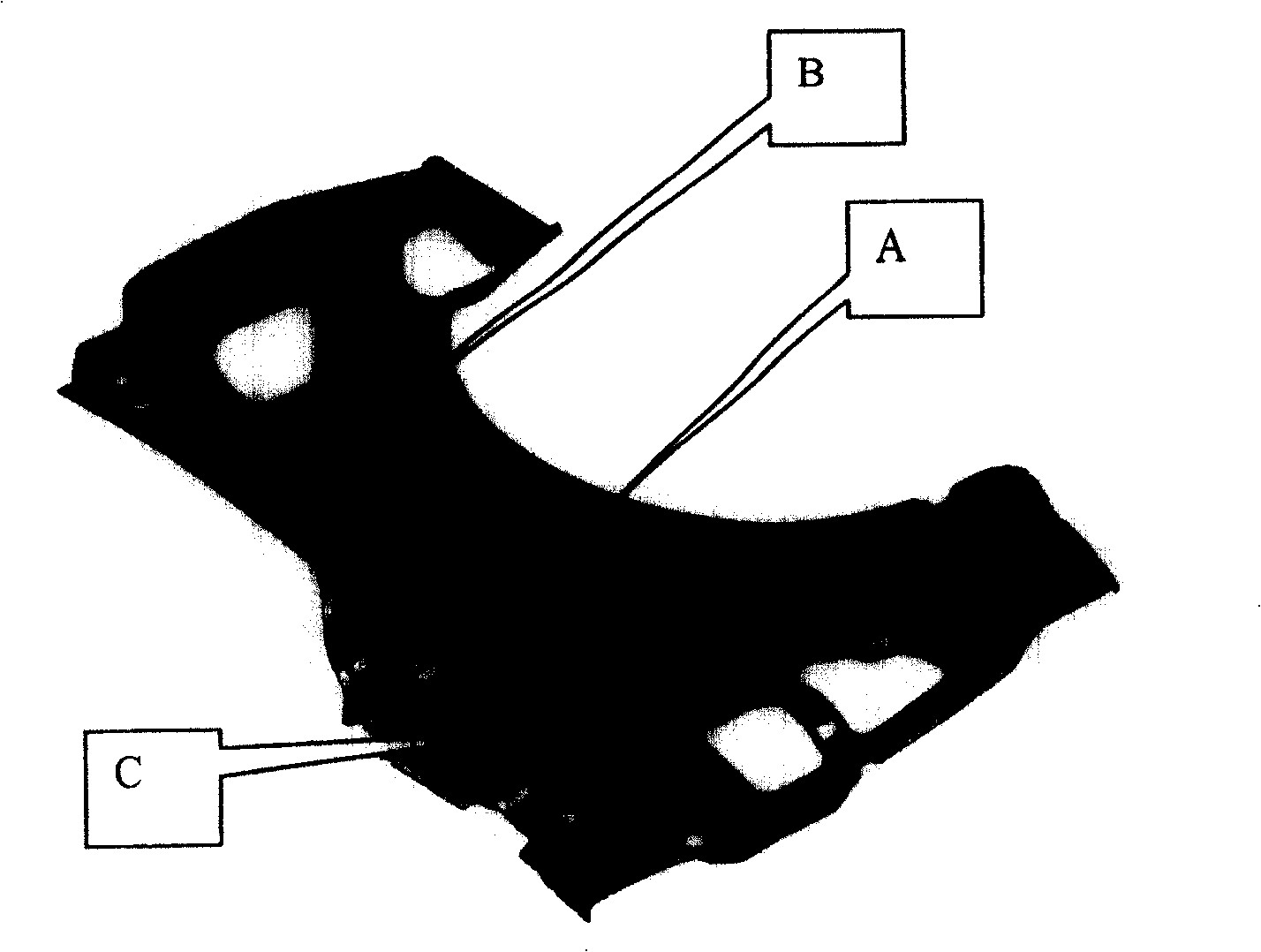

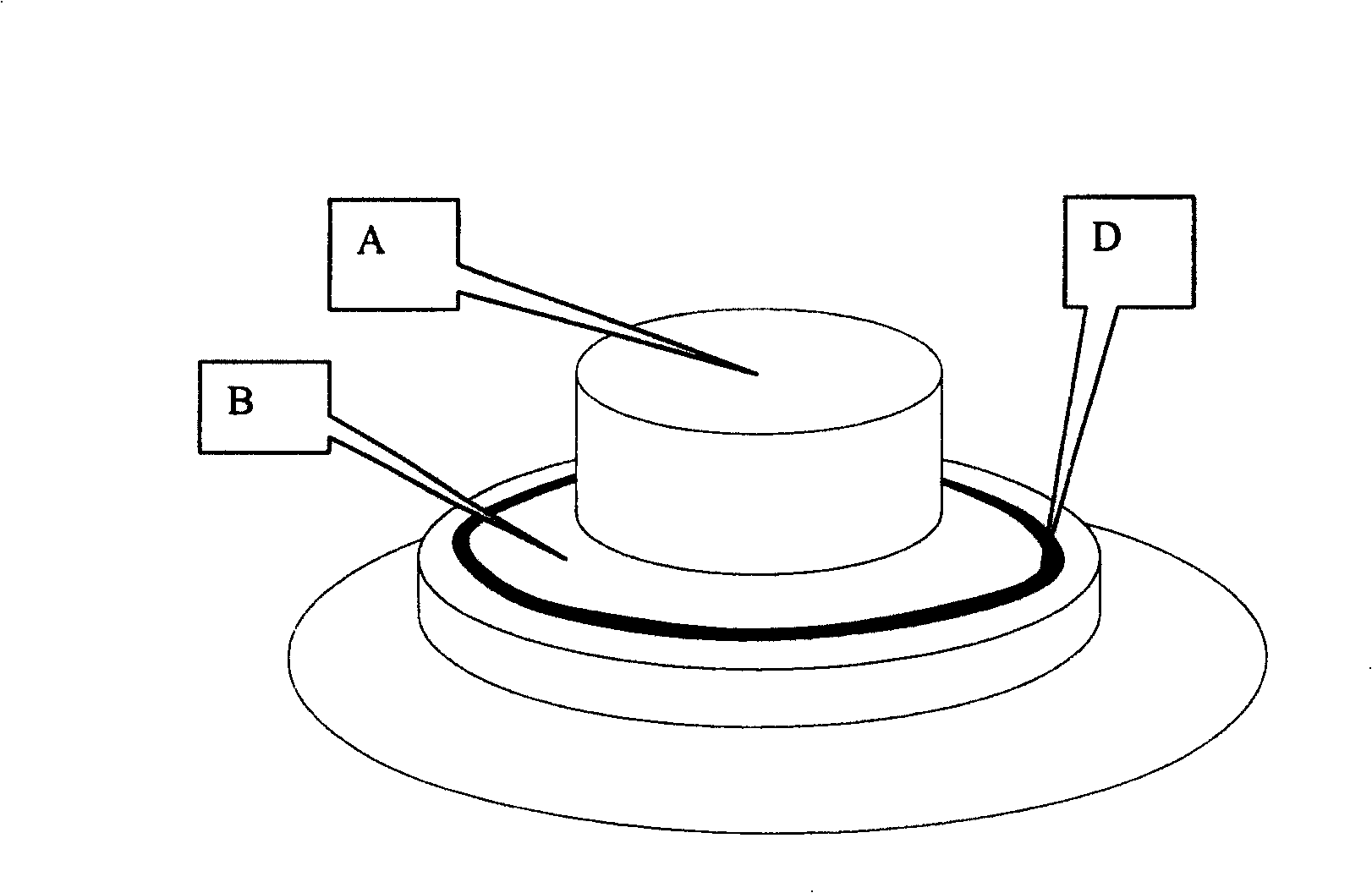

[0019] Such as figure 1 and figure 2 As shown, for drawn parts with complex shapes such as automobile rear side panels, not only the drawing shape is irregular, but the drawing height is generally not equal. Some parts are drawn to a high height, as shown in Part A (for convenience, this article is called "high-end material"); some parts are drawn to a relatively low height, as shown in Parts B and C (this referred to as "low-end material"). and, if figure 2 As shown, the height between the high-end material and the low-end material is sometimes not equal, for example, the height between the A part and the B part and the height between the A part and the C part are not equal. In addition, the heights of the high-end materials themselves may be unequal, or the slopes or inclinations of the edges of the high-end materials may also be unequal, such as 90 degrees or 60 degrees, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com