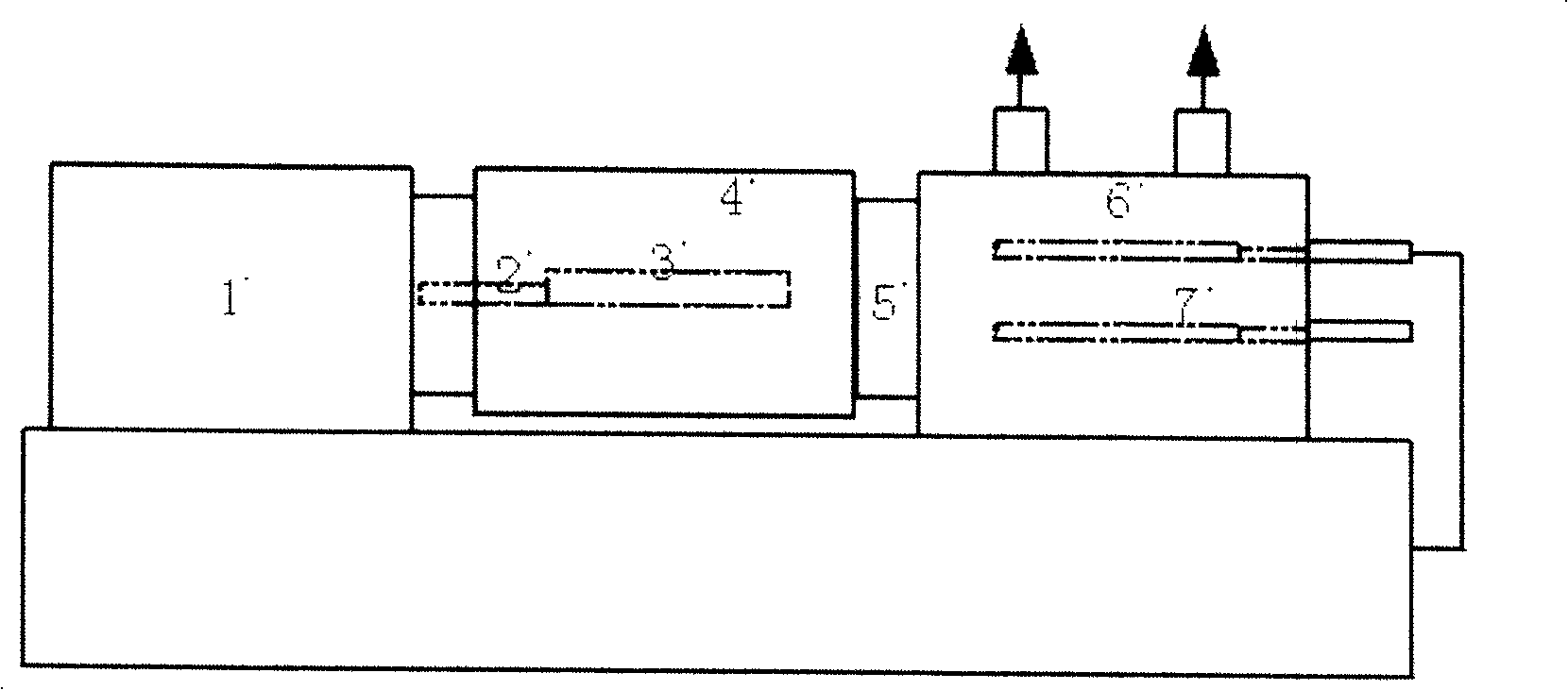

Quick cooling test plant for disk type band steel, and method of use

A technology of rapid cooling and test equipment, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of cooling speed influence, large mutual influence, poor sealing, etc., achieve high cooling speed, large sample size, and eliminate poor sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

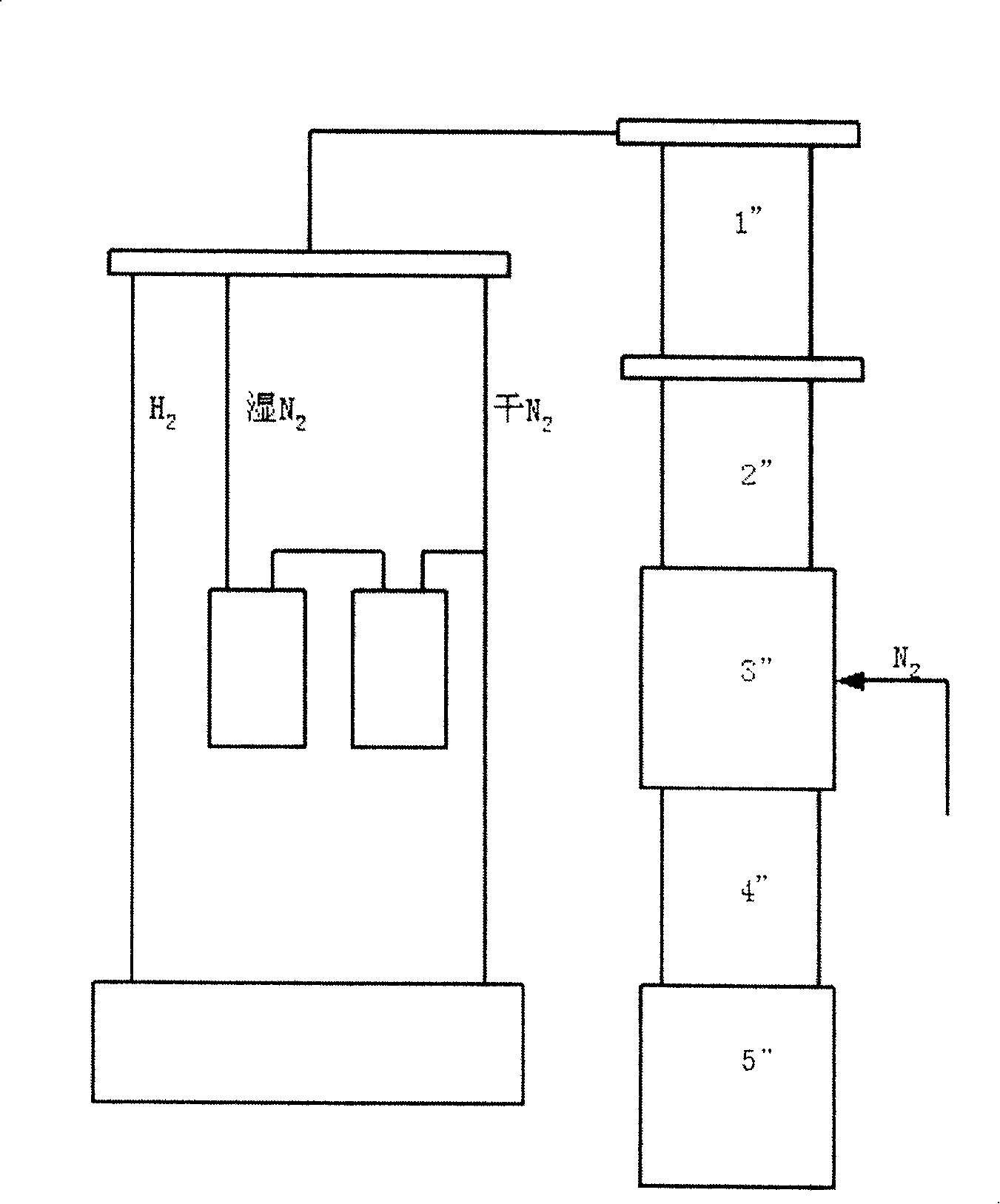

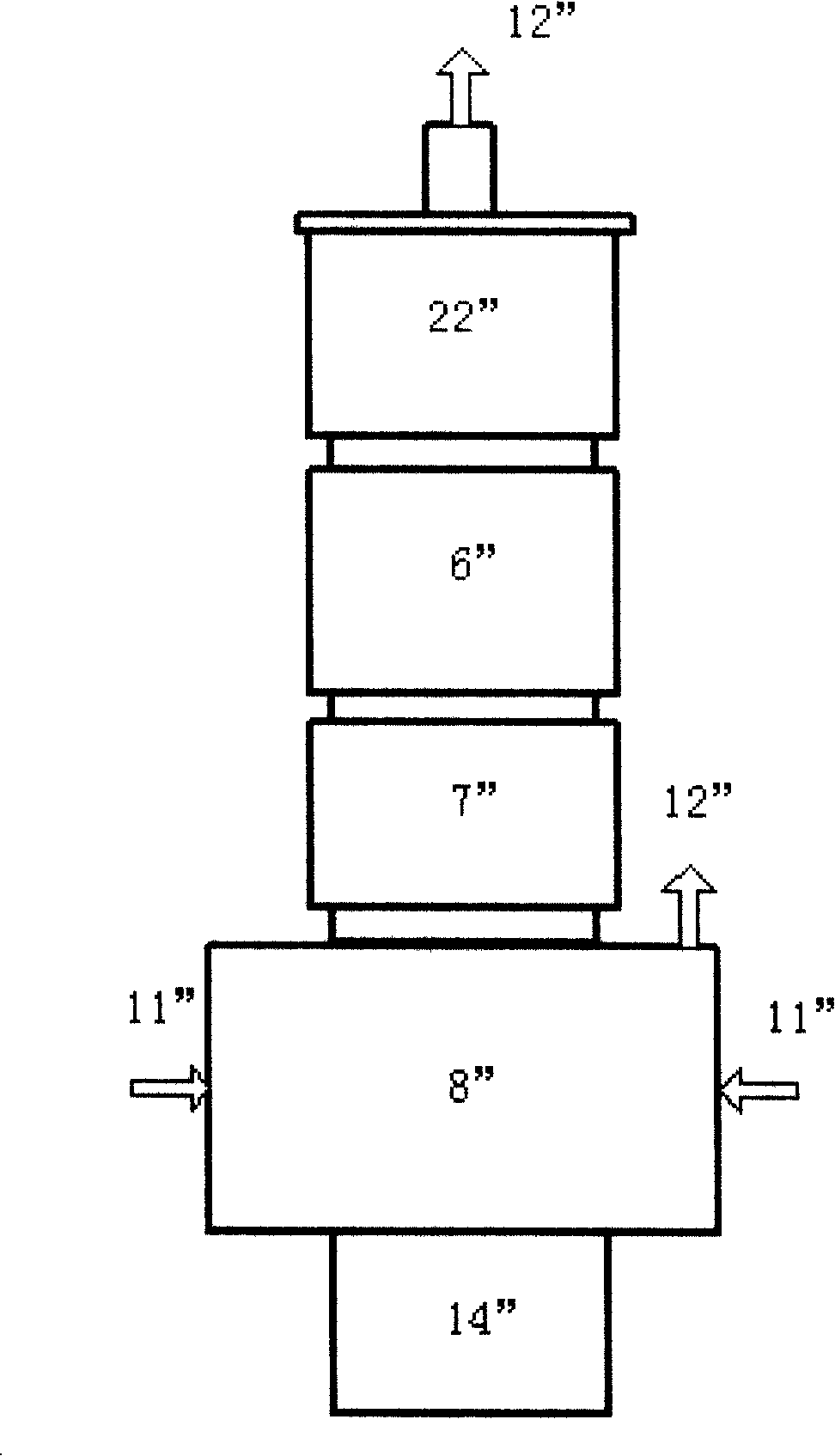

Method used

Image

Examples

Embodiment Construction

[0037] The invention adopts hydrogen, nitrogen and water as the cooling medium for rapid cooling, and is equipped with gas mist two-phase nozzles, which can realize full hydrogen cooling, nitrogen cooling, hydrogen + nitrogen cooling, hydrogen + nitrogen + water mist cooling, hydrogen + water mist cooling, Nitrogen + water mist cooling, water mist cooling, water quenching cooling and other cooling methods. The thermal conductivity of hydrogen is about 7 times higher than that of nitrogen, and it is a reducing atmosphere, which is very beneficial to the heating and cooling of strip steel, and is an ideal cooling medium. Water is a safe and cheap liquid cooling medium, and its thermal conductivity is much higher than that of gaseous cooling medium, which is very beneficial to the manufacture of high-strength steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com