Method for focus plasma beam mending with precisivelly positioning

A focused ion beam and precise positioning technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of easy damage to other circuits around and difficult alignment of integrated circuit target positions, etc. Easy to remove, easy to take out the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the process of the present invention, the present invention will be further described below in conjunction with examples, but these examples do not limit the present invention.

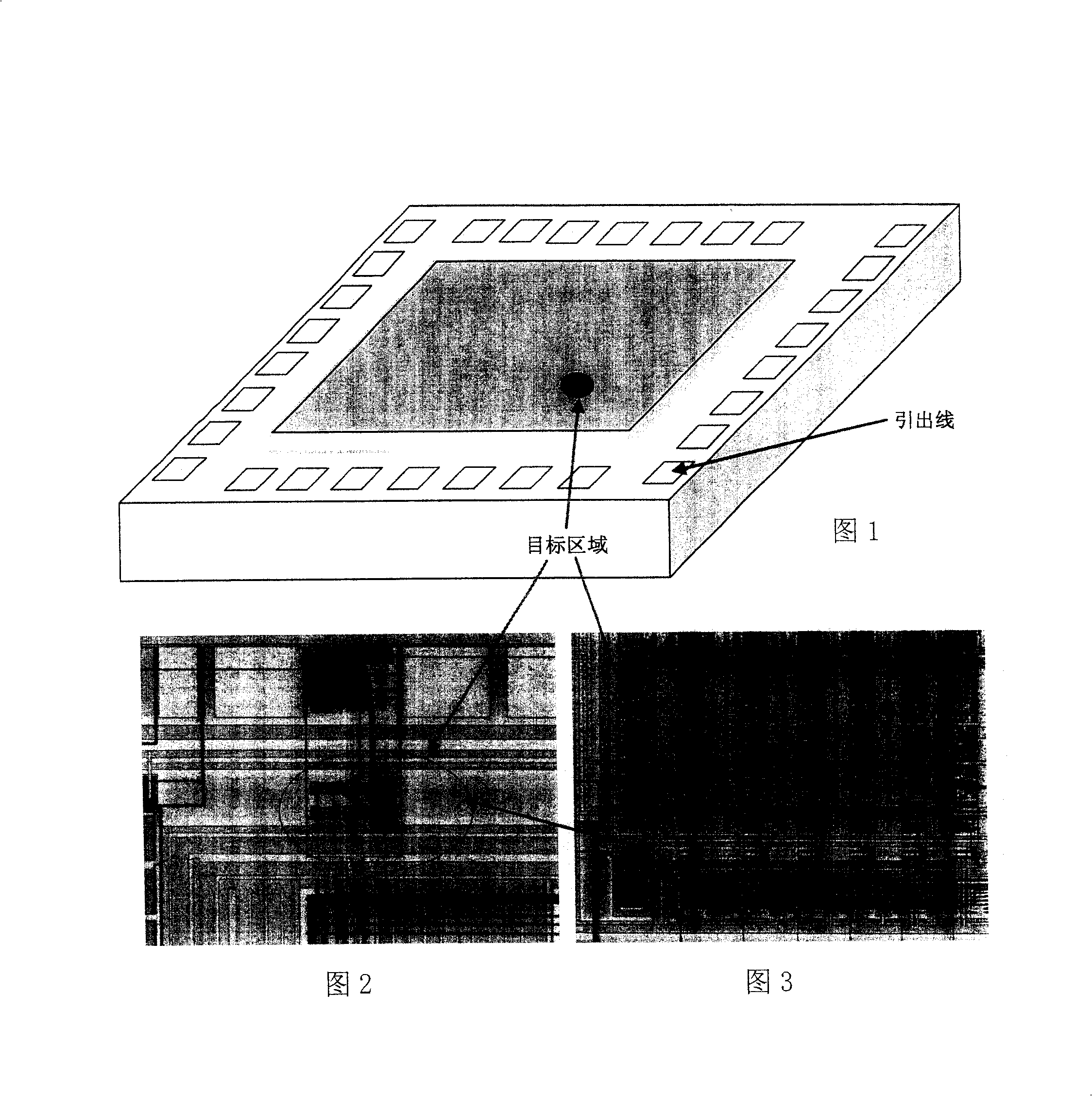

[0023] The sample to be processed has a 6-layer metal structure, and the target metal layer is the third layer of metal. The appearance and structure of the sample are shown in Figures 1 to 3.

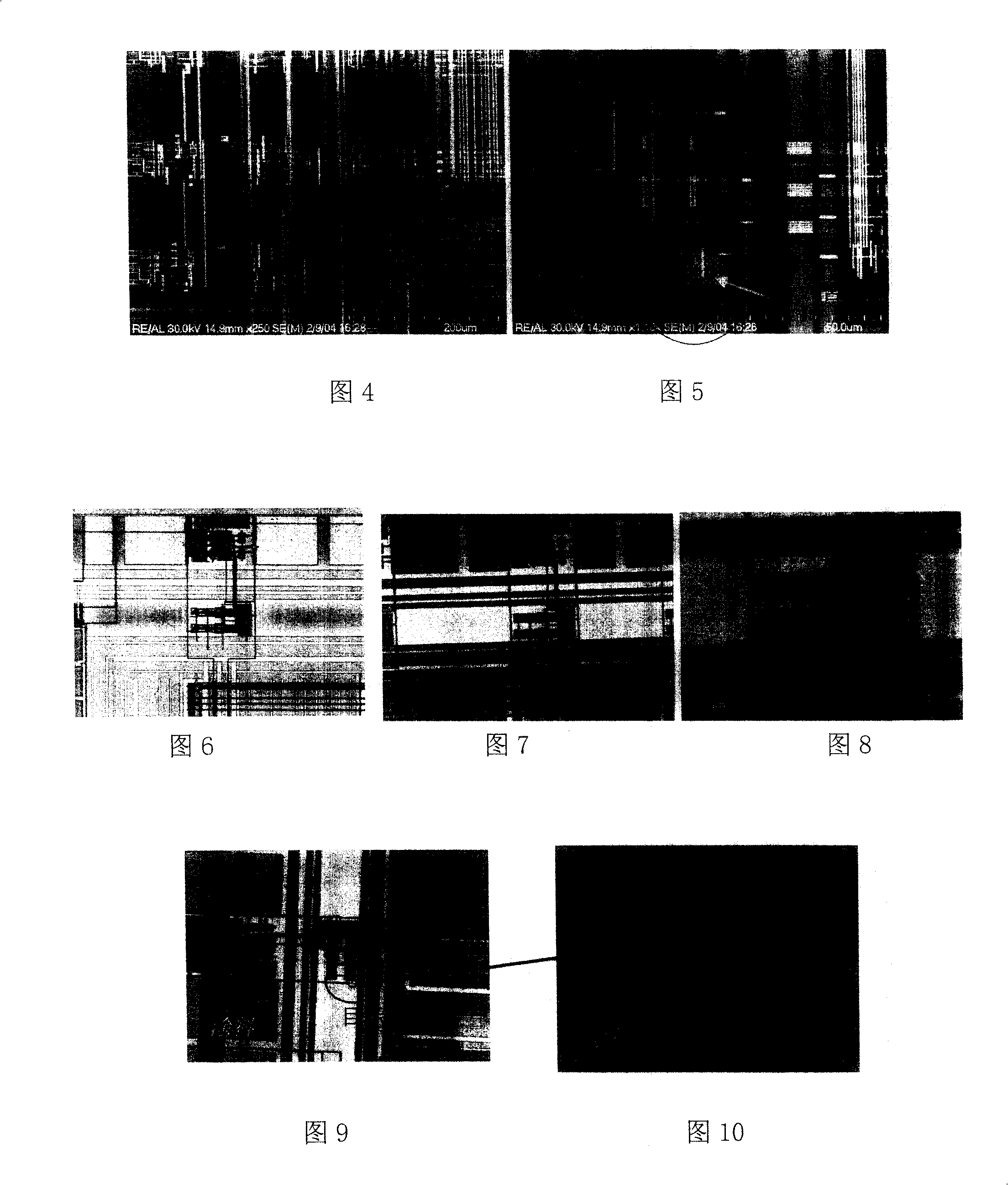

[0024] First use reactive ion etching (RIE) to etch the passivation layer deposited on the target metal layer to about 0.5 μm, and the pictures obtained by observing with an electron microscope are shown in Figure 4 and Figure 5, where the oval area is the target area, The block indicated by the arrow is the target point;

[0025] Apply a layer of transparent insulating paint on the surface of the test sample. The paint used is a mixture of paraffin wax and rosin at a ratio of 2:1, and the proportion of paraffin wax can be 40% to 90% [w / w] to make the paint uniform. Coat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com