Press button module and its producing method

A component and button technology, which is applied in the field of button components and its manufacturing, can solve the problems of reduced productivity, high failure rate, and increased failure rate, and achieve the effects of improving productivity, reducing production costs, and simplifying production engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the button assembly and its manufacturing method of the present invention will be described in detail below with reference to the accompanying drawings.

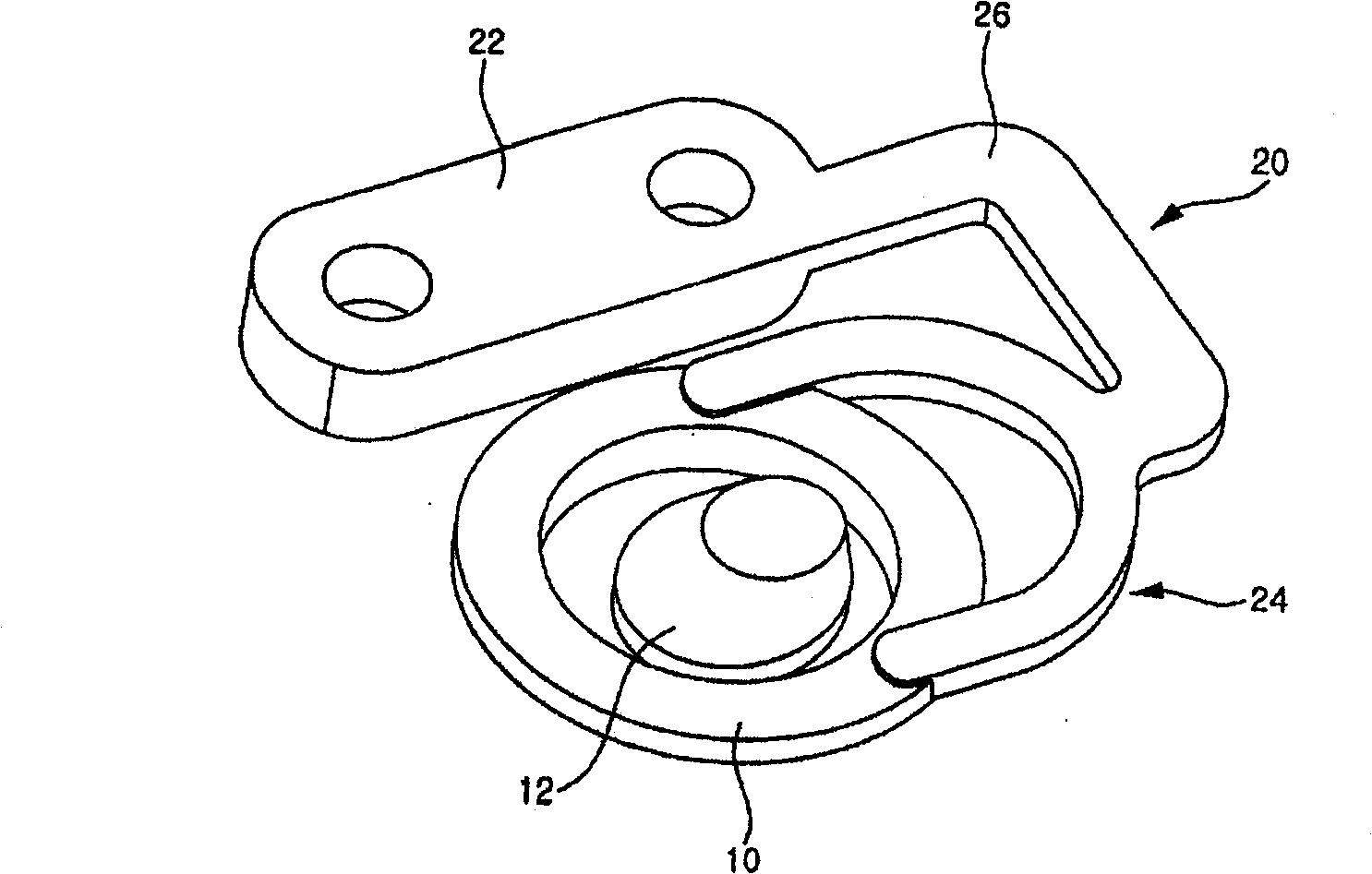

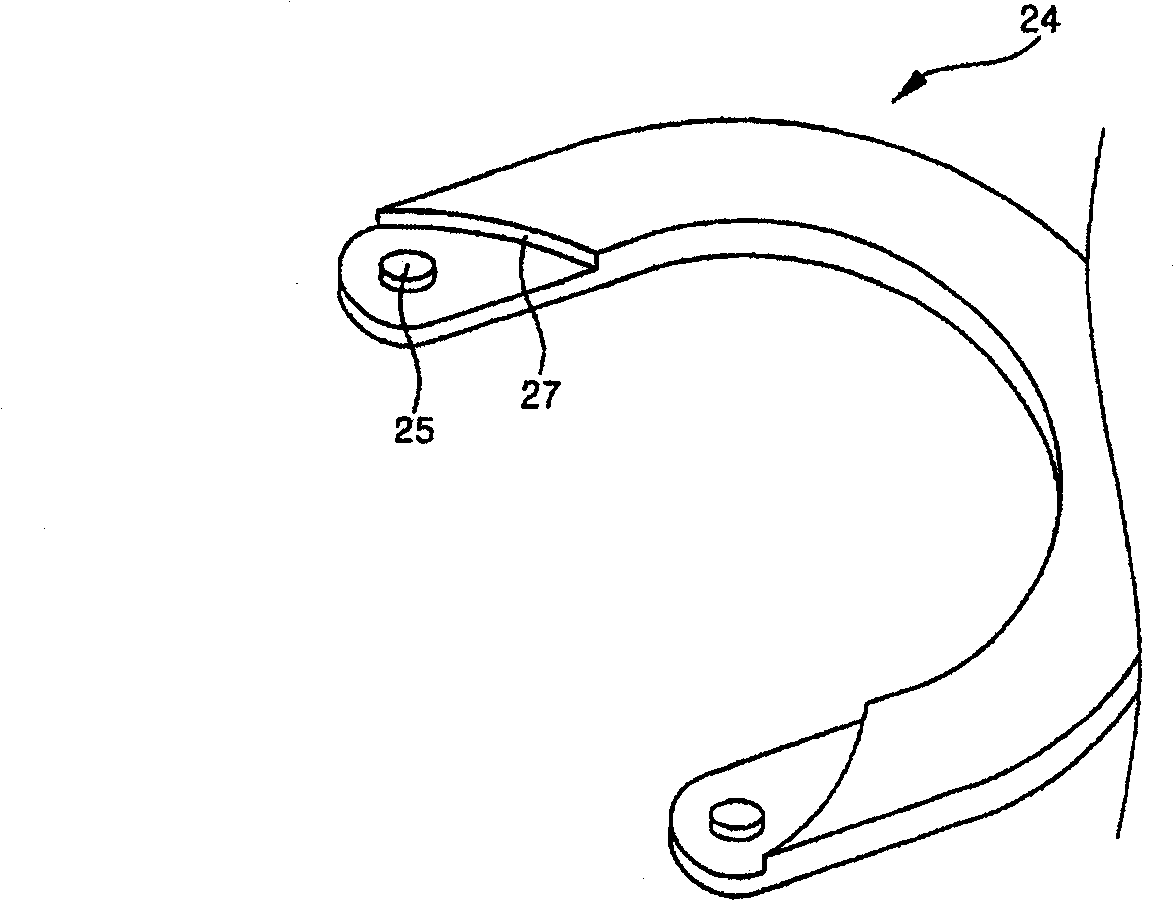

[0022] figure 1 It is a schematic perspective view of the button assembly of the present invention. Such as figure 1 As shown, the button assembly of the present invention is composed of the following parts: a pressing part 10 that is exposed at the front and can be pressed by the user; a tension part 20 that is connected to the pressing part and can elastically restore the pressing part and act.

[0023] The above-mentioned pressing part 10 is a part that the user presses through the part exposed on the front of the electronic product. Therefore, it is preferable to perform gold plating on the surface of the above-mentioned pressing part 10 in consideration of the beauty of its appearance. In order to perform such a gold-plating treatment, the above-mentioned pressing portion 10 is made of ABS resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com