Method for producing a motor vehicle lock by targeted oblique punching of the locking faces of a locking part

A technology for motor vehicles and locking surfaces, which is applied in the application of locks, building locks, vehicle locks, etc., can solve problems such as troubles, and achieve the effect of reducing noise load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

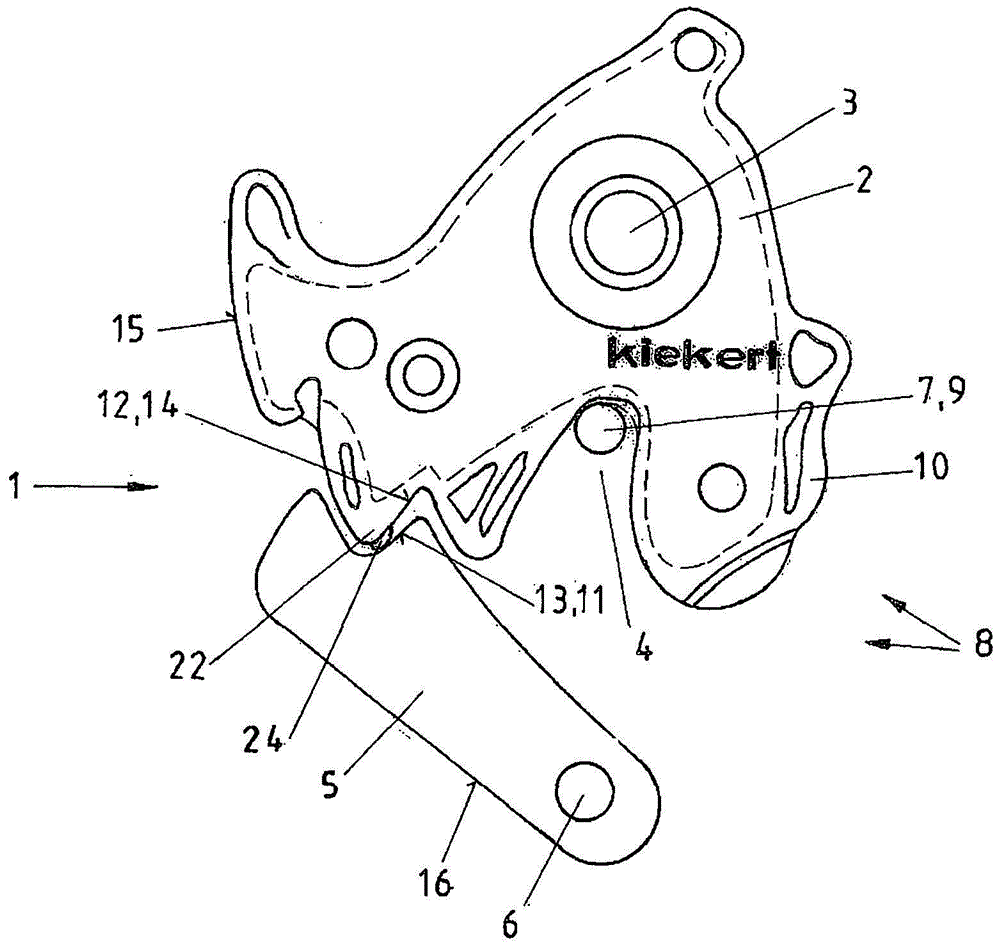

[0023] figure 1 A plan view of a motor vehicle lock 1 with two locking parts 30 , 31 is shown, wherein a rotary locking fork 2 pivotable on an axis 3 is secured by a pawl 5 . A locking bow 7 with a locking bow leg 9 is located in the receptacle 4 of the rotary locking fork 2 .

[0024] The rotary locking fork 2 is secured by the pawl 5 which is pivotable about the pawl axis 6 , that is to say, the motor vehicle lock 1 can only be reactivated if the pawl 5 has been swung away beforehand (this is achieved by a door handle not shown here). Open.

[0025] In order to be able to securely surround the locking bow leg 9 of the locking bow 7 , the rotary locking fork 2 has a correspondingly designed receptacle 4 . It is considered here that the locking bow 7 with the locking bow leg 9 is assigned to the chassis of the motor vehicle, while the locking device 8 with the rotary locking fork 2 and the pawl 5 is assigned to the motor vehicle door.

[0026] It is not emphasized in partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com