Humidifying bottle with separated outlet

A technology for humidifying bottles and bottle caps, applied in respirator and other directions, can solve the problems of low process accuracy requirements, multiple users, difficult installation, disassembly or separation, etc., to achieve the effect of reducing water noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

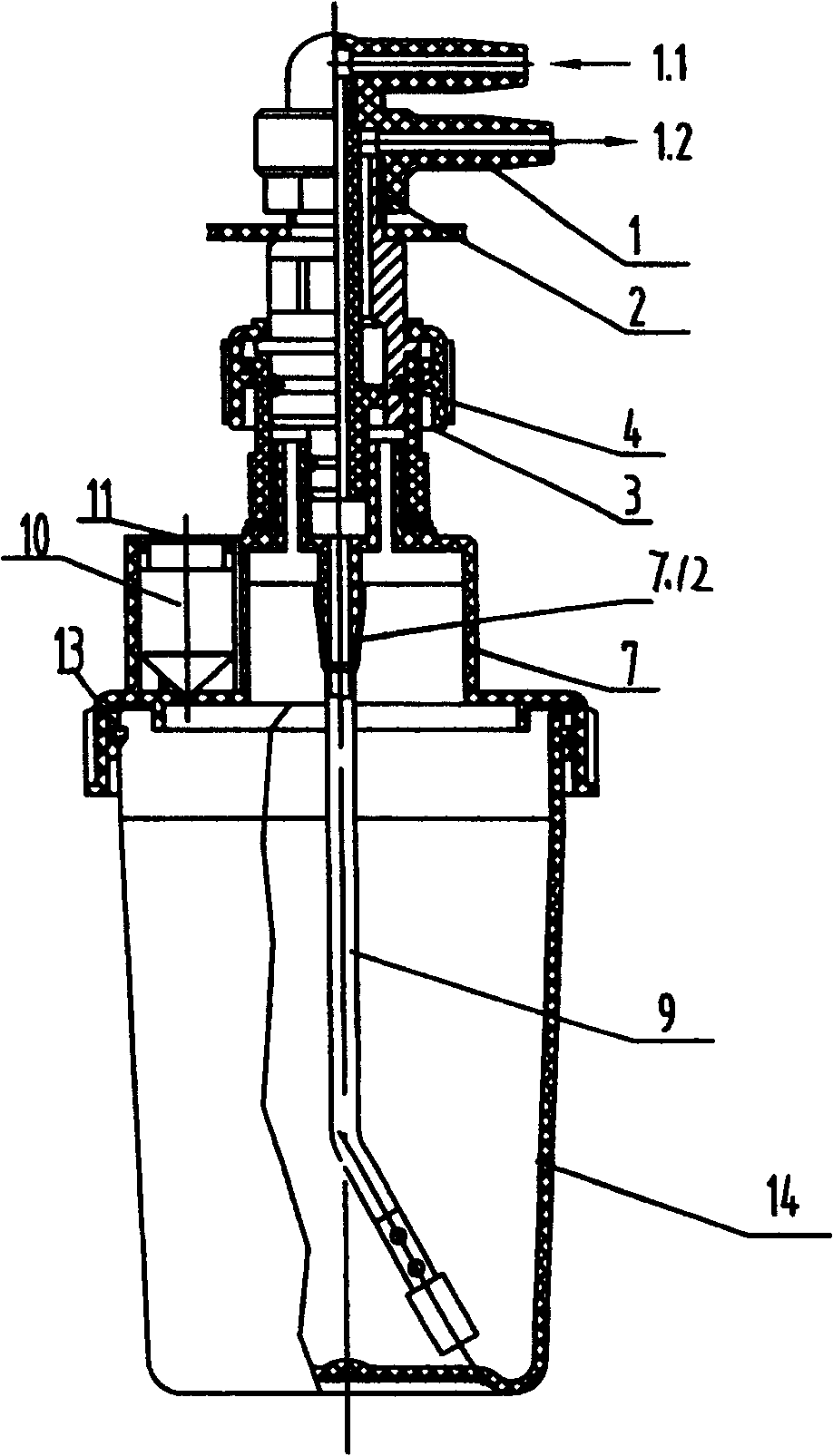

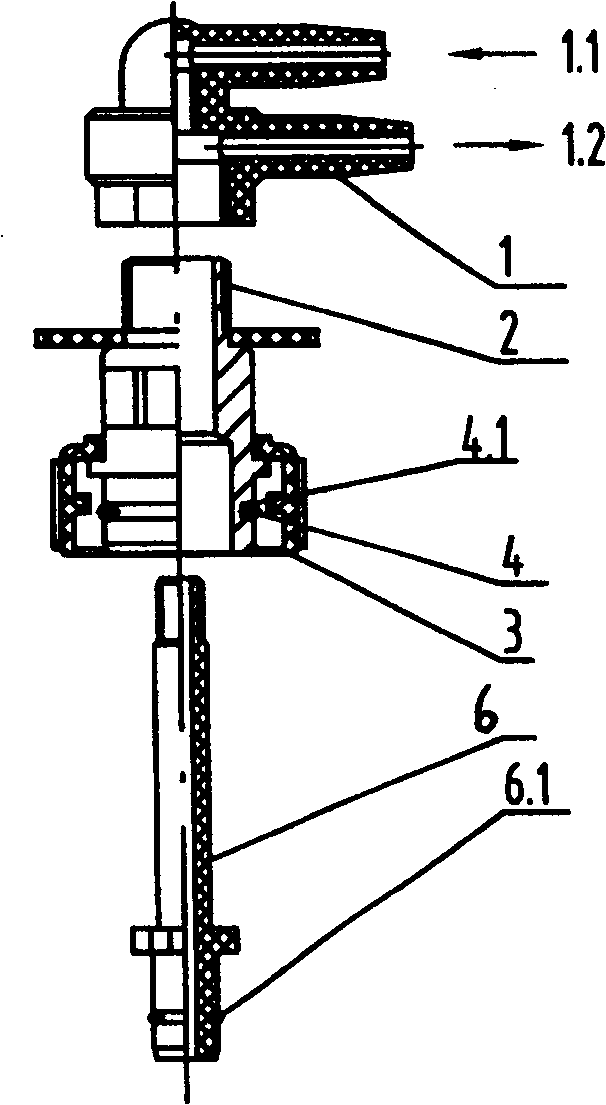

Embodiment 1

[0036]The air intake and exhaust joint 1 is composed of an oxygen inlet 1.1 and an oxygen outlet 1.2, the air intake and exhaust joint and the outer wire plug 2 are threadedly connected, and the outer wire plug 2 is provided with an O-ring groove 4.1, an O-ring groove 4.1 An O-shaped sealing ring 4 is installed inside to ensure that the oxygen will not leak; the connecting cover 3 is set on the outer wire plug 2, and the connecting cover 3 is provided with a double-headed locking spiral slope 13 corresponding to the connecting socket 5 for Connect and fix the outer wire plug 2 and the connection socket 5; the oxygen inlet connector 6 is inserted into the outer wire plug 2, the oxygen inlet pipe of the oxygen inlet port is connected, and is sealed with the oxygen inlet connector 6, and an O-shaped seal is set on the oxygen inlet connector 6 Circle 6.1 to ensure no leakage and mixing between the oxygen in and out; the upper edge of the connecting socket 5 is provided with a doubl...

Embodiment 2

[0039] A baffle is added on the humidification bottle from the bottle cap to the bottom of the bottle body to separate the humidification bottle into two sealed parts, each part has its own humidification bottle core, and each humidification bottle core is connected with its own Oxygen inlet connection.

[0040] The inlet and exhaust joint 1 is composed of an oxygen inlet 1.1 and an oxygen outlet 1.2, and an end cover 16 and a retaining ring 17 are arranged on the top; O-ring groove 4.1, O-ring groove 4.1 is equipped with O-ring 4 to ensure that oxygen will not leak; the connecting cover 3 is set on the outer wire plug 2, and the connecting cover 3 is provided with a corresponding connection socket 5 The double-headed locking spiral slope 13 is used to connect and fix the outer wire plug 2 and the connection socket 5; the oxygen inlet connector 6 and the oxygen outlet connector 15 are inserted in the outer wire plug 2, and the oxygen inlet pipe of the oxygen inlet port communi...

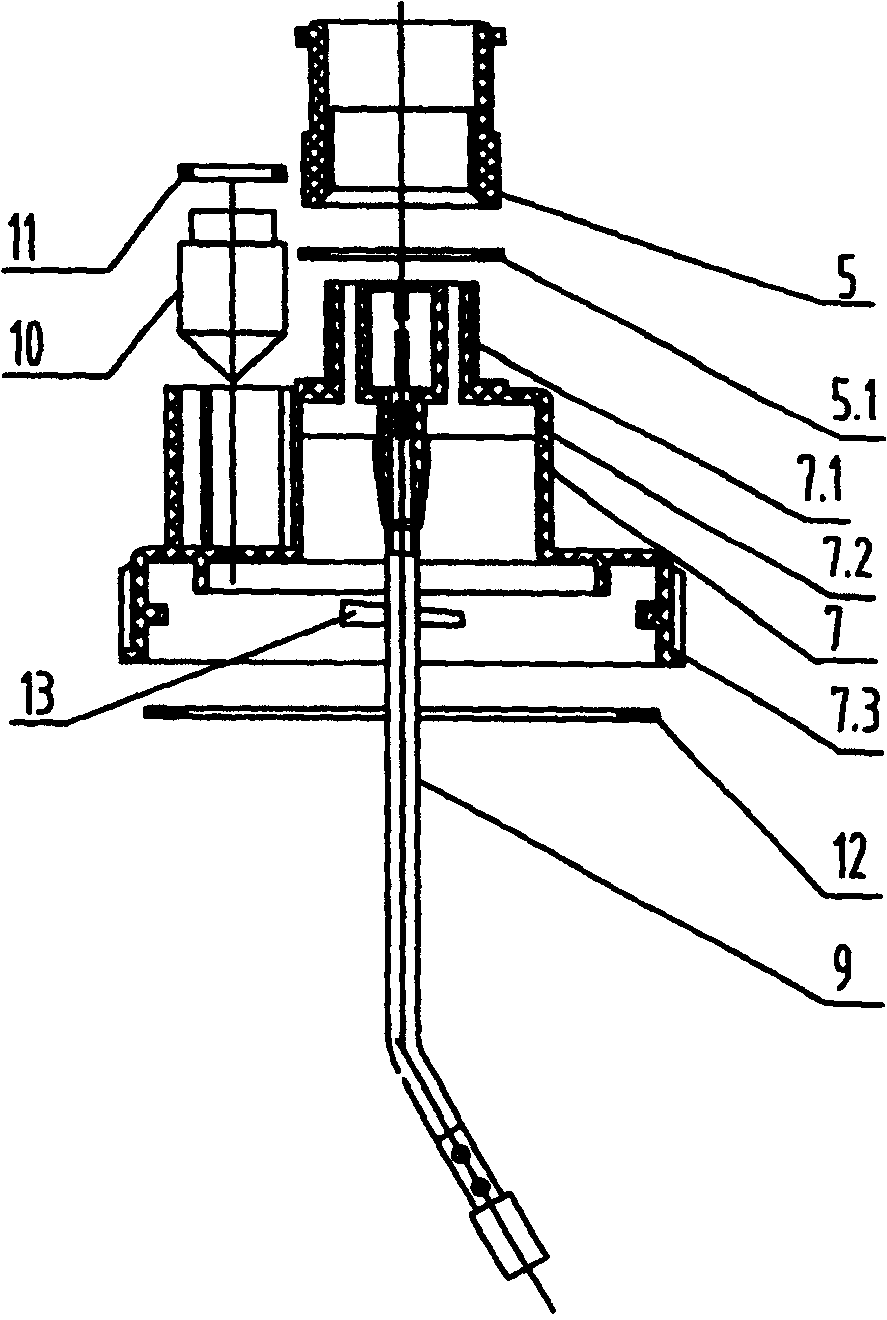

Embodiment 3

[0044] A baffle 20 is added inside the humidification bottle. The baffle 20 is from the inlet and outlet joints to the bottom of the humidification bottle, and separates the humidification bottle into two sealed parts. Each part has its own set of parts. Its own humidification bottle core, each humidification bottle core is connected with its own oxygen inlet pipe.

[0045] The air intake and exhaust joint 1 is composed of an oxygen inlet 1.1 and an oxygen outlet 1.2, the air intake and exhaust joint and the outer wire plug 2 are threadedly connected, and the outer wire plug 2 is provided with an O-ring groove 4.1, an O-ring groove 4.1 An O-shaped sealing ring 4 is installed inside to ensure that the oxygen will not leak; the connecting cover 3 is set on the outer wire plug 2, and the connecting cover 3 is provided with a double-headed locking spiral slope 13 corresponding to the connecting socket 5 for Connect and fix the outer wire plug 2 and the connection socket 5; the oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com