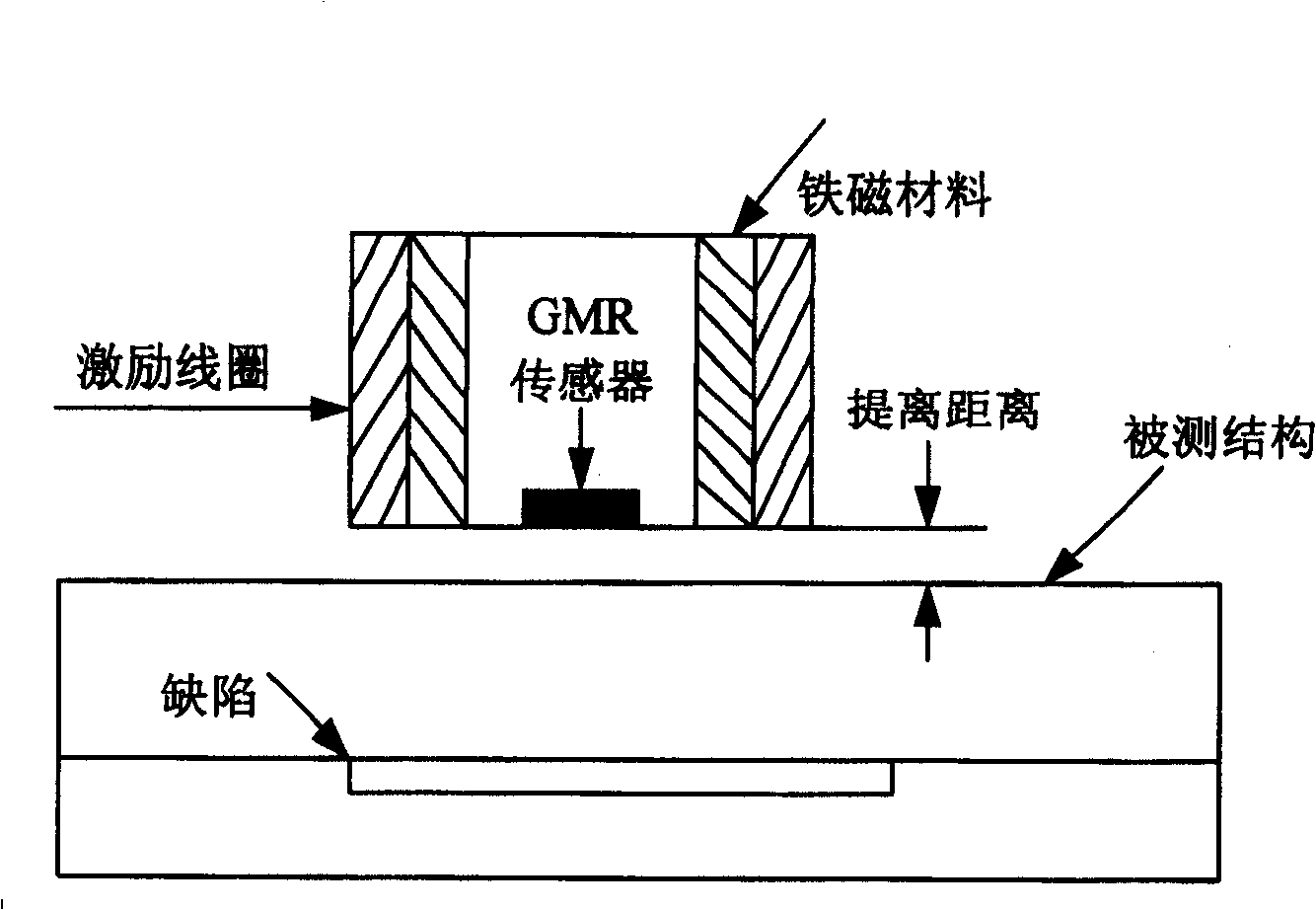

Eddy current inspection device based on resistance transducer of gigantic magnetism

A giant magnetoresistance and eddy current detection technology, which is applied in the direction of material magnetic variables, can solve the problems of multi-layer structure sensitivity and insufficient spatial resolution, increased detection signal distortion, and low detection coil sensitivity, so as to suppress zero point drift , The detection signal distortion is small, the effect of convenient adjustment of the working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The device of the invention adopts a high-sensitivity and high-resolution detection probe based on a giant magnetoresistance sensor, and its operating frequency can be continuously adjusted in the range of 0-10KHz, and can be used for the detection of deep defects in multi-layer conductive structures in important fields such as aerospace .

[0024] First, fix probe 1 and probe 2 on the top of the standard part and the DUT respectively as required; press the trigger zero button to make the output of the instrument zero; determine the control parameters such as excitation frequency and gain, and download them to the MCU controller; set the scanning speed of the scanner, and start the scanner controller. The scanner controller controls the movement of the scanner, so that the probe 2 scans the object under test as required.

[0025] After that, the signal generating circuits I and II generate two quadrature sine waves, wherein the output signal of the excitation signal ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com