Manufacturing method of chromo coextructing safety equipment and mould

A safety equipment and co-extrusion technology, applied in the field of utility poles, can solve the problem of no longer warning and safety of light poles or guardrails, and achieve the effect of obvious installation location, easy implementation and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

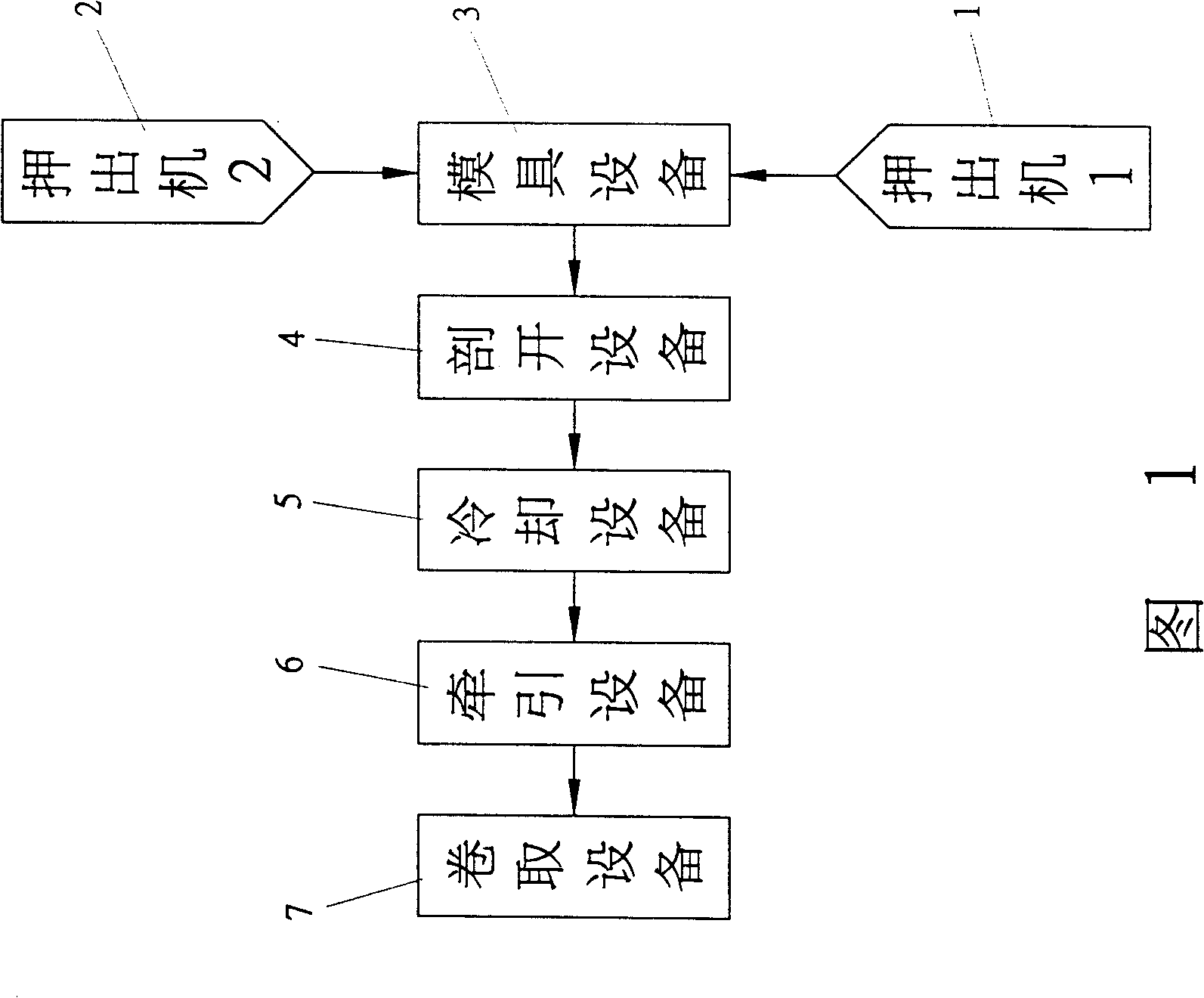

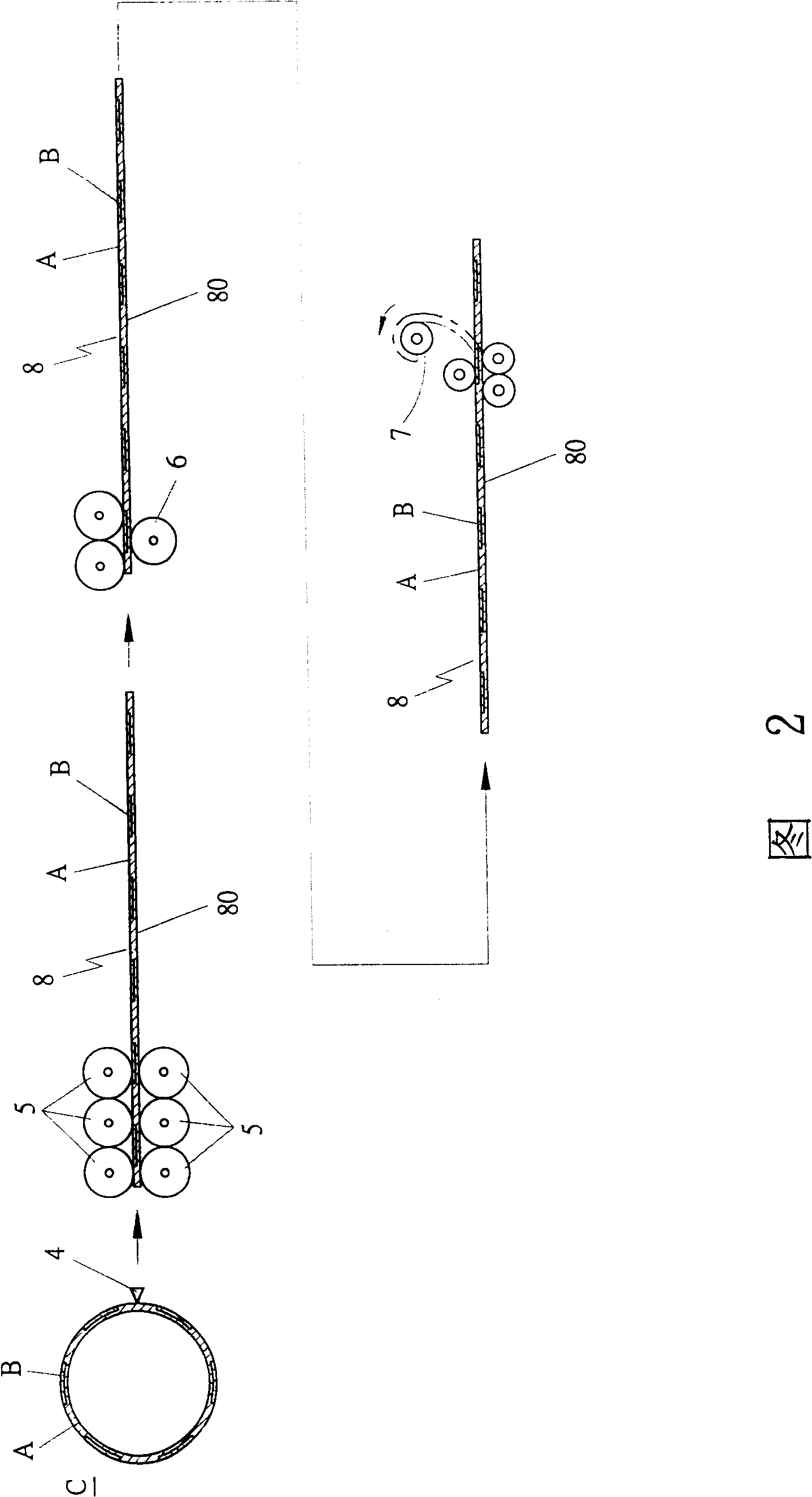

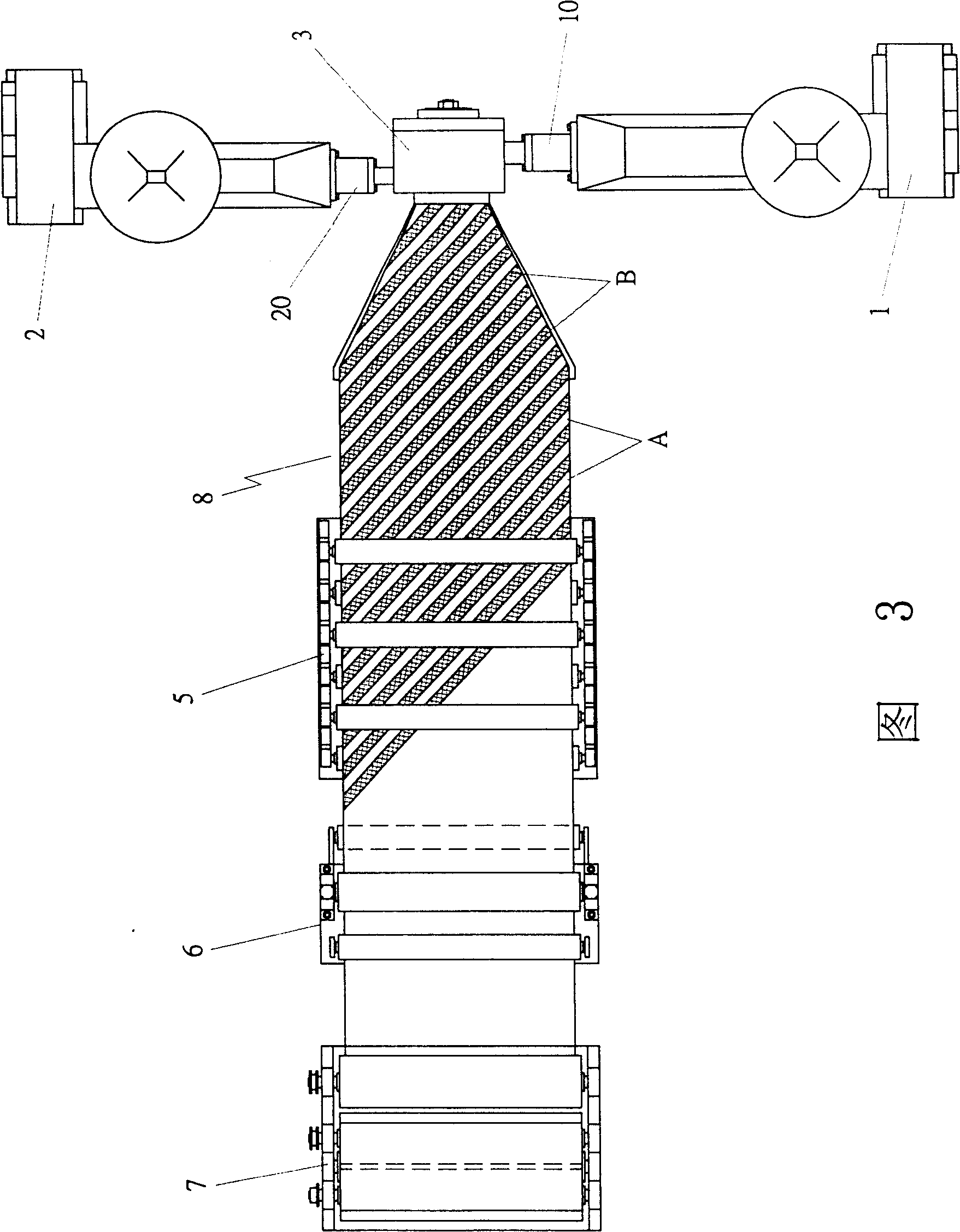

[0067] Relevant technical means that the present invention adopts for reaching above-mentioned purpose and effect is described in detail as follows with embodiment now in conjunction with accompanying drawing:

[0068] As shown in Figure 1-3, wherein the first embodiment of the present invention's preparation method is made of polyvinyl chloride (PVC); Or polyethylene (PE); Or cross-linked flame-resistant polyethylene (PE) compound; Or polypropylene (PP) and other monomers; or compound plastic raw materials A and B that are available and of different colors, are extruded into the mold 3 through the extruder 1 and the extruder 2, and the mold 3 has the function of co-extrusion of different colors (such as Figure 15 shown), wherein raw material A (black or other darker colors) is extruded through the extruder 1 to the annular channel 320 of the inner mold base 32, and then the raw material A reaches the outlet 303 of the outer mold base 30 through the feed channel 321. Raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com