Anti-blowing out device for reusable anti-blowing plug

An early warning device and anti-blowout technology, which is applied in the direction of transmission device, fluid transmission device, heating/cooling contact switch, etc., can solve the problems that the anti-blowout plug affects the operation of the equipment, has no early warning function, and cannot be reused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

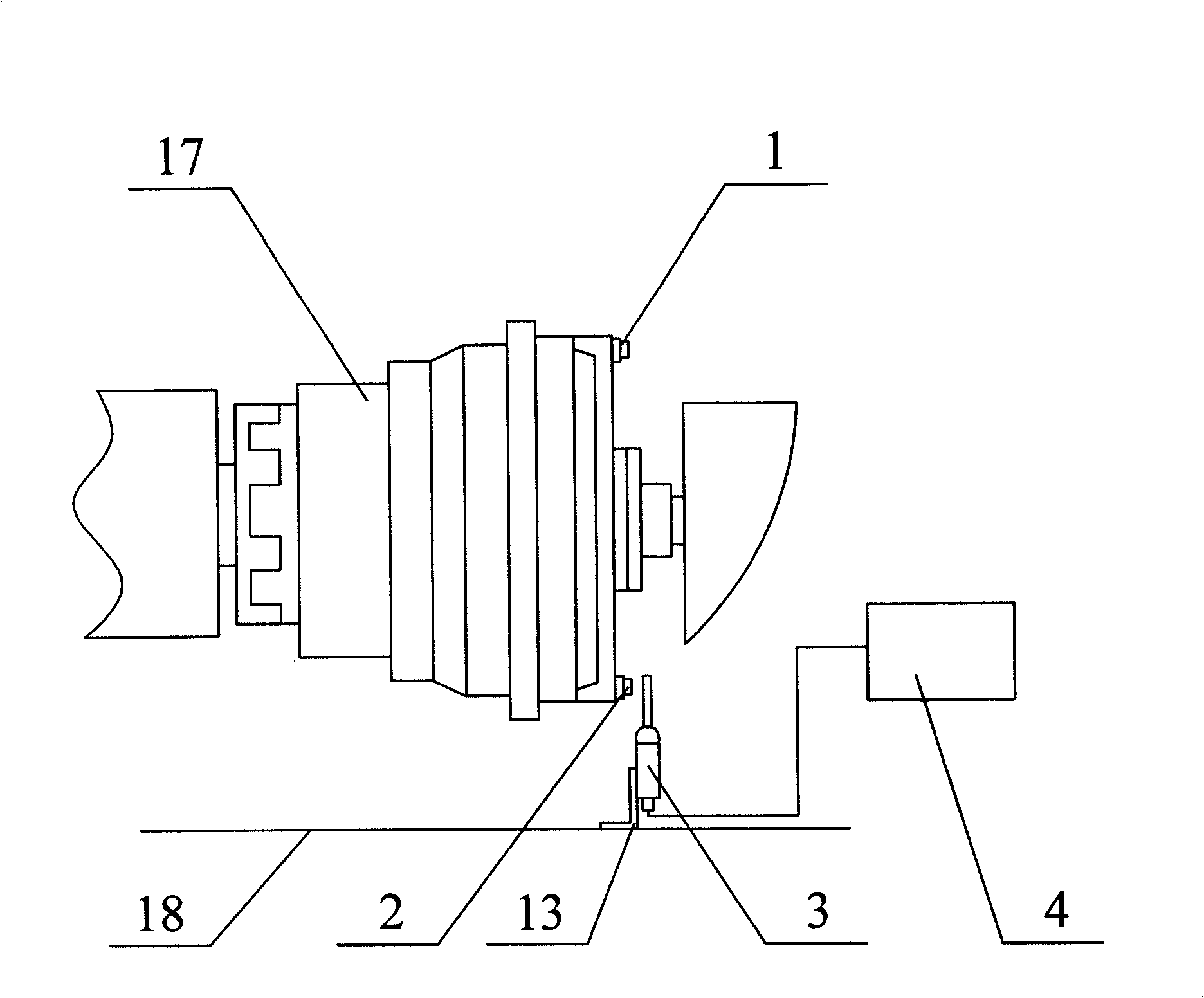

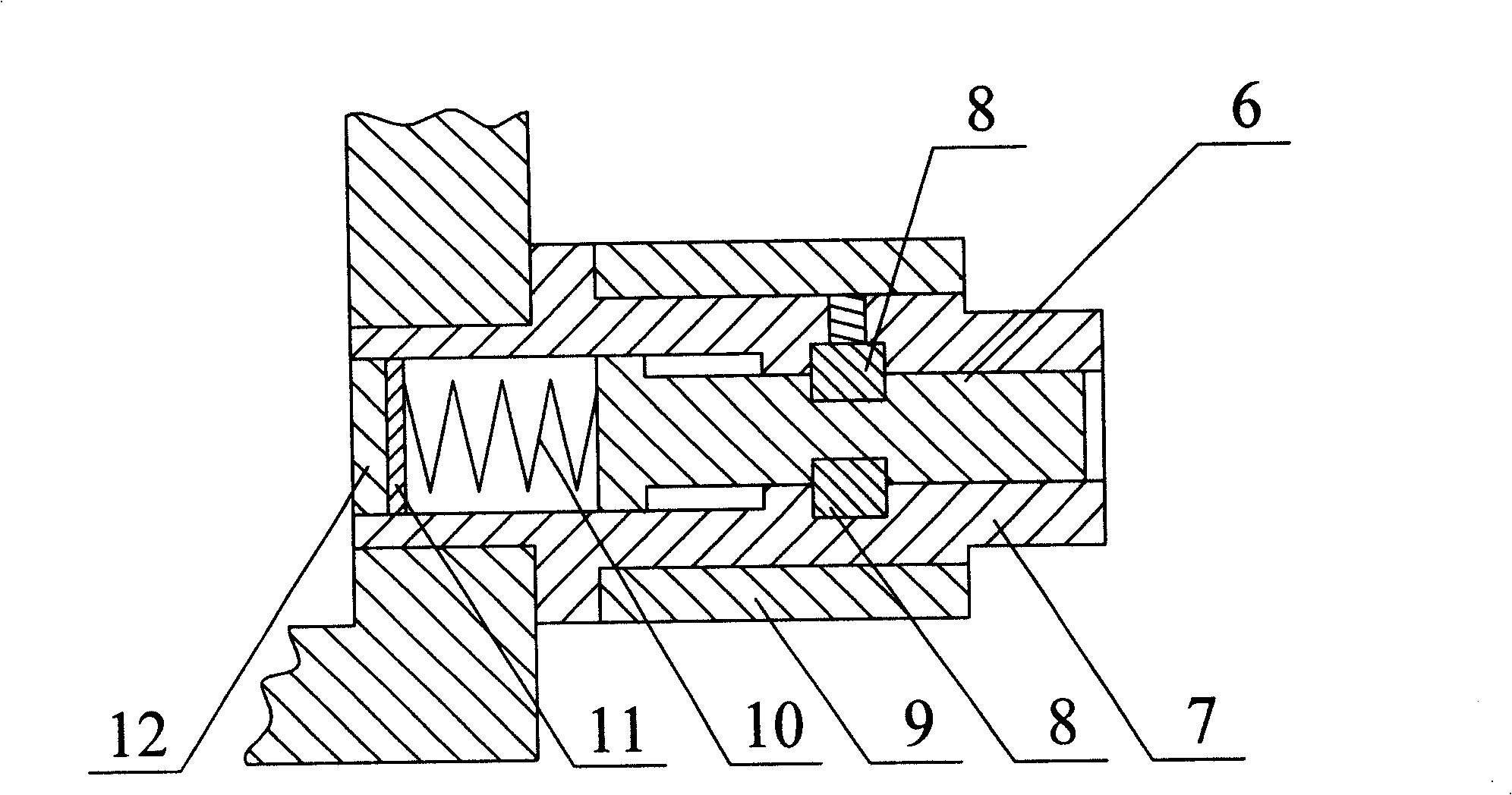

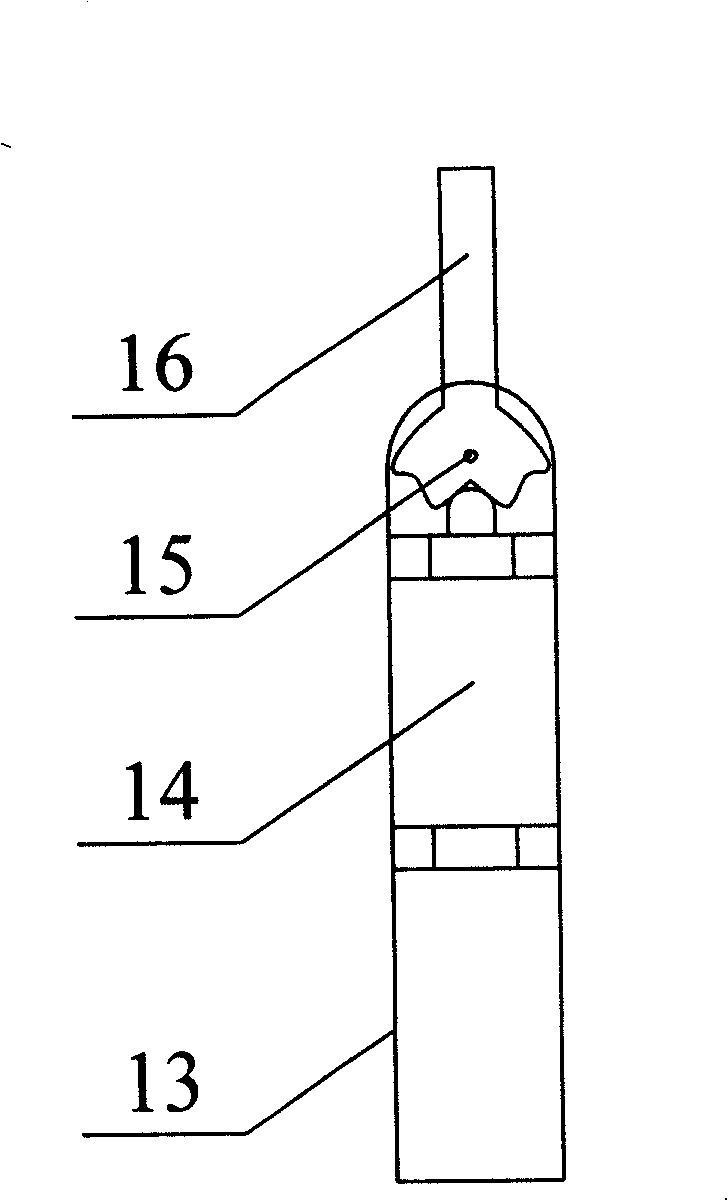

[0007] In conjunction with the embodiment, it is specifically described as follows: as shown in the accompanying drawings figure 1 As shown, the blowout prevention warning device for repeated use of the blowout prevention plug is composed of a secondary protection fusible plug 1, a blowout prevention plug 2, a special swing switch 3, and an electric controller 4. The fusible alloy melting point of the secondary protection fusible plug 1 is 130°C ± 5°C, and the early warning protection control temperature of the blowout preventer 2 is 110°C ± 5°C, which are respectively installed in the torque-limiting hydraulic coupling 17 driven by the pump wheel There are two places on the same circumference of the pump wheel or the end face of the casing. When the blowout plug 2 fails due to an accident, the pump wheel drives the torque-limiting hydraulic coupling 17 to continue to heat up until it reaches the rated temperature of the secondary protection fusible plug 1. The fusible alloy m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com