Hermetic compressor

A closed compressor and compression mechanism technology, applied in compressors, liquid variable capacity machinery, refrigerators, etc., can solve problems such as increased power consumption, weakened refrigeration capacity of refrigerators, and reduced actual volume, and achieves sealing performance. The effect of improving, improving energy efficiency, and stabilizing the amount of inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

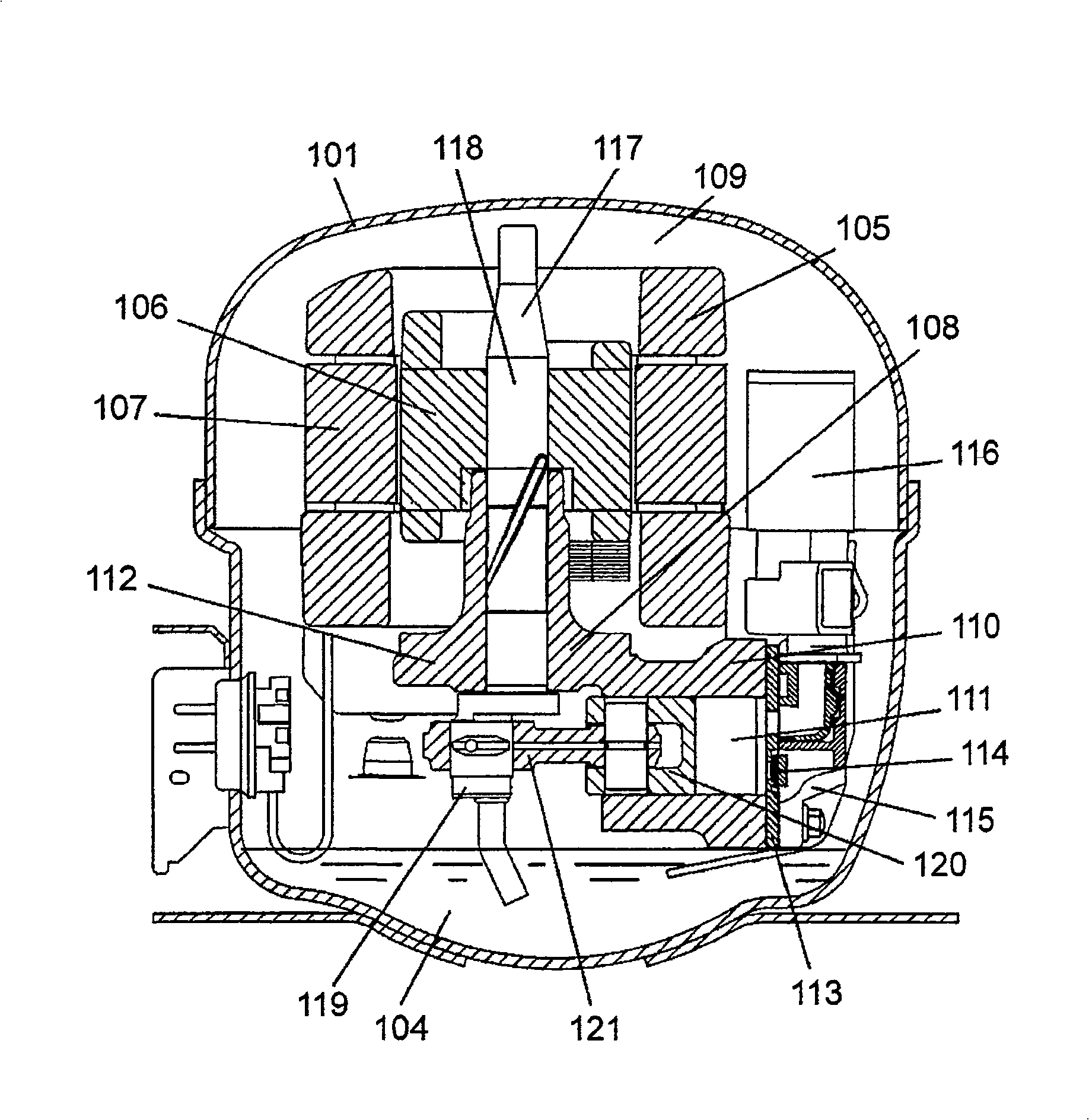

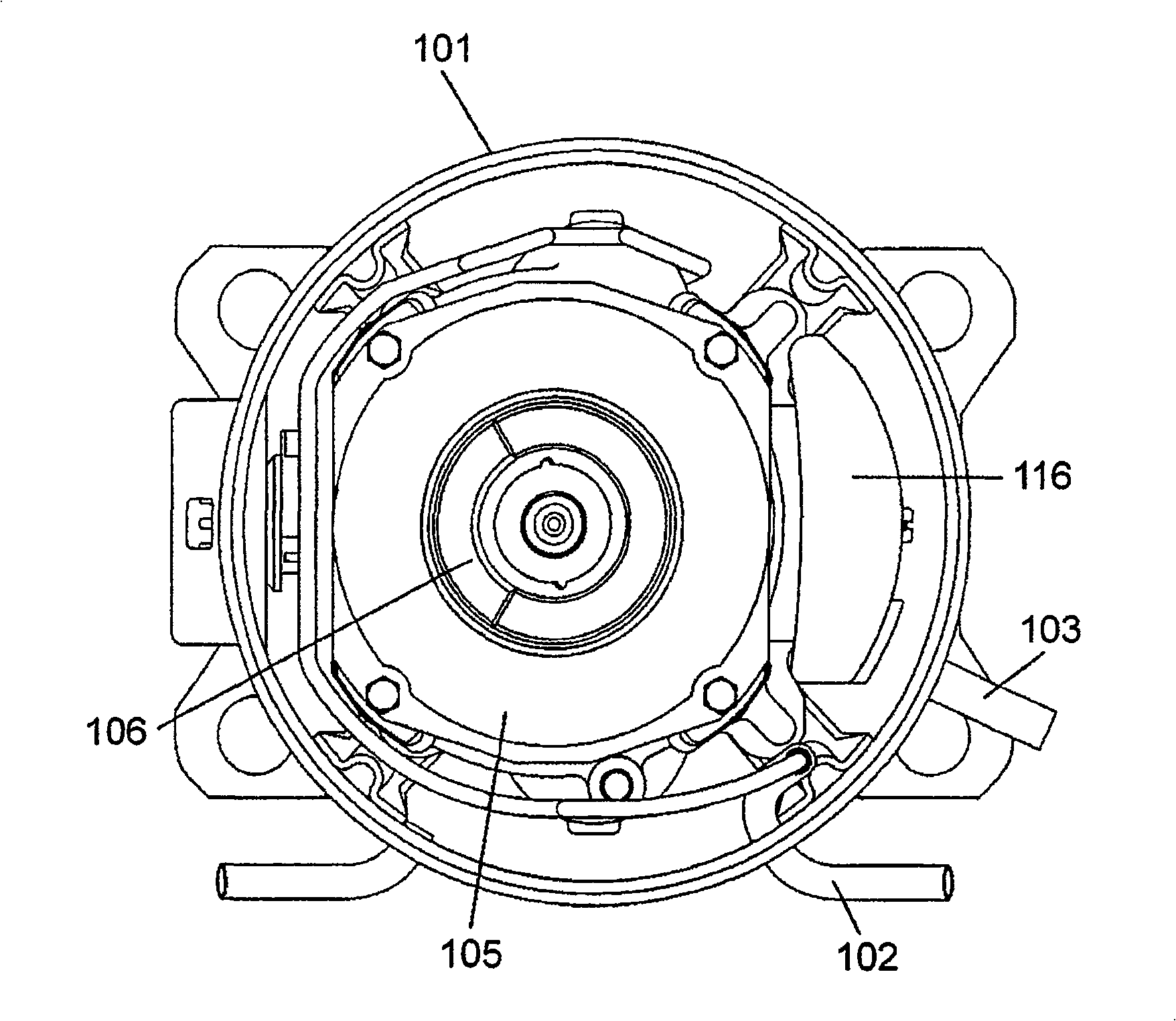

[0040] The container 101 is equipped with an exhaust pipe 102 and an air suction pipe 103, both of which are connected to a cooling system (not shown); at the bottom thereof, organic oil 104 is stored; inside it is housed an electric component 107, which comprises a stator 105 and a rotor 106, and a compression mechanism 108 rotationally driven by an electric component 107. The container 101 is filled with refrigerant 109 .

[0041] Due to environmental problems in recent years, it is preferable that the refrigerant 109 has nothing to do with chlorofluorocarbons (CFCs), but refrigerants such as R134a and R600a are used.

[0042] Next, the main components of the compression mechanism 108 will be described.

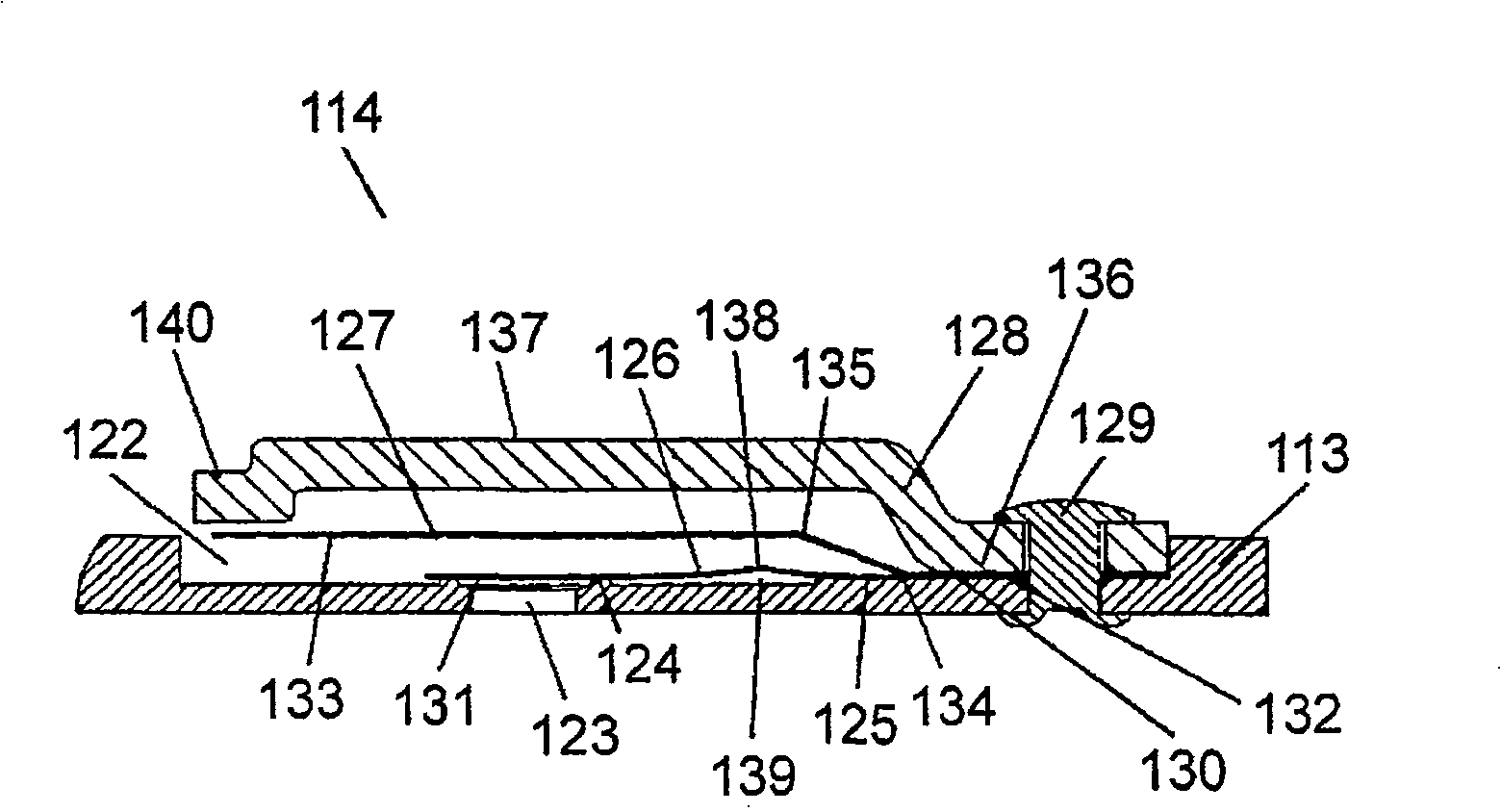

[0043] The cylinder 110 is equipped with a substantially cylindrical compression chamber 111 and a bearing portion 112 . Of the two sides of the valve plate 113 , the side opposite to the contact with the cylinder 110 is equipped with an exhaust valve device 114 to close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com