Method for producing zip fastener

A manufacturing method and technology of zippers, applied in the field of zipper manufacturing, capable of solving problems such as shedding, deflection, and impact of pins and pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

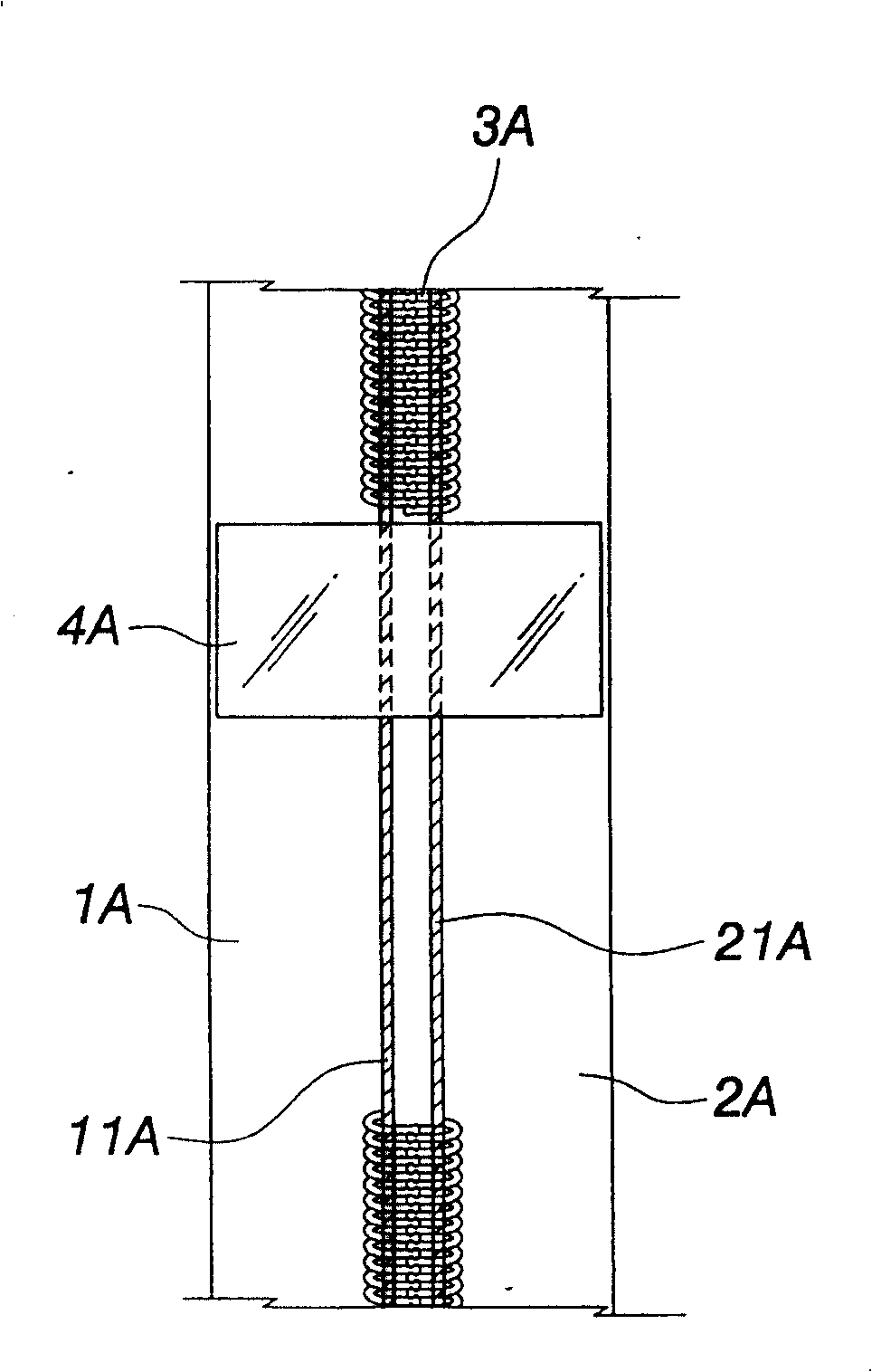

[0029] The detailed description and technical content of the present invention are as follows in conjunction with the accompanying drawings:

[0030] The present invention is a "manufacturing method of zipper", please refer to Figure 4 Shown is the flow chart of the slide fastener forming steps of the present invention, and the forming steps are as follows:

[0031] (A) sprocket forming or timing forming, the cloth tapes 1 and 2 are first input into the injection molding machine, so that the cloth tapes 1 and 2 are injection-molded with sprocket 3;

[0032] (B) patch and elongated slit: a patch 4 is respectively fixed at the upper and lower positions of the insert pin 63 and the solid tip 64 on the cloth tapes 1 and 2, and a long patch 4 is punched on the patch 4. Shaped slit 41, the elongated slit 41 does not cover the yarn core 11, 21 (cord) on both sides of the cloth tape 1, 2, and an auxiliary flow channel for ultrasonic trimming is provided at the appropriate position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com