Block polymer and antistatic agent comprising the same

A technology of block polymers and polymers, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problems of resin mechanical strength and moldability decline, insufficient compatibility, mold pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0338] As for the preparation method of the block polymer (A2), there can be mentioned a method comprising reacting (a4)-(a6) with (b2), and a method comprising, for example, the presence of (a4) during the preparation of (b2). The following method reacts the precursor (reactant) of (b2) to simultaneously form the polymer (b2) block and the block polymer (A2).

[0339] In the case where (b2) is polyetherester amide (b2-1), its production method is not particularly limited, but includes the following methods.

[0340] Those block polymers (A2) in which (b2) is a polymer segment other than polyetheresteramide (b2-1) can be prepared in the same manner.

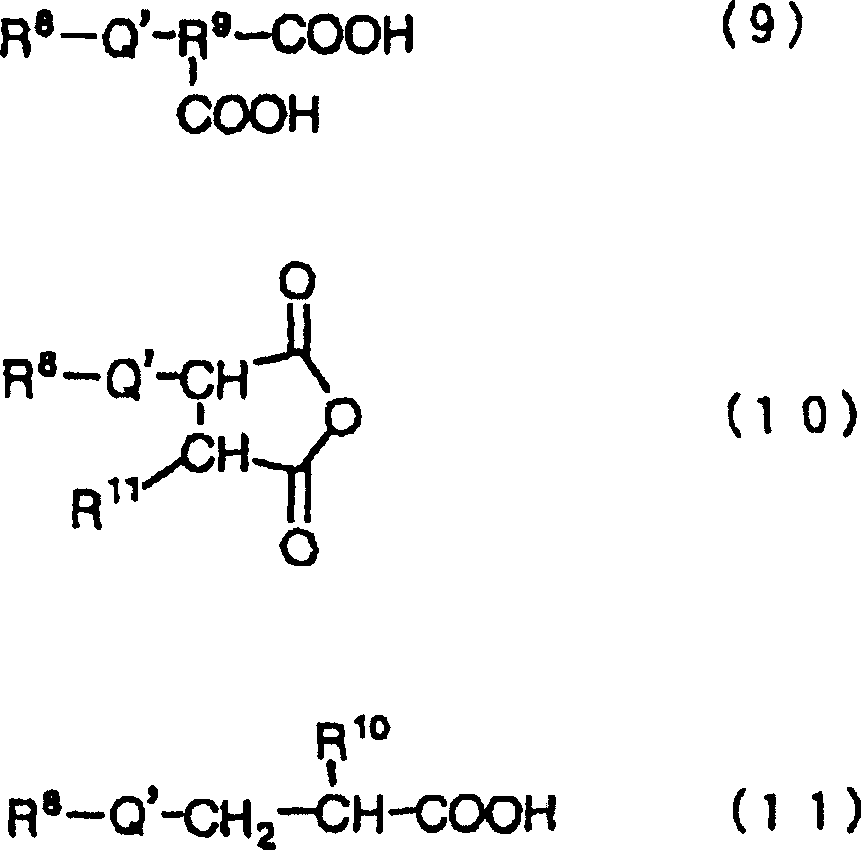

[0341] Method 1: A method comprising polymerizing (a4-1) represented by general formula (9) and polyether ester amide (b2-1) at 200-250°C under reduced pressure.

[0342] Method 2: A method comprising polymerizing (a4-1), (Q1) and (b1-1) at 200-250°C under reduced pressure.

[0343] Method 3: Comprising one or more of (a4-1), (...

preparation Embodiment 1

[0470] Under nitrogen, 85 parts of low molecular weight polypropylene having a Mn value of 2,500 obtained by thermal degradation and a density of 0.89 was melted together with 15 parts of maleic anhydride at 200° C. for 20 hours.

[0471] Then, excess maleic anhydride was distilled off under reduced pressure to obtain acid-modified polypropylene (a1-1①).

[0472] (a1-1①) has an acid value of 39.8 and a Mn value of 2,800.

preparation Embodiment 2

[0474] Low molecular weight polypropylene (80 parts) with a Mn value of 2,500 obtained by thermal degradation and a density of 0.89 (80 parts) was melted together at 160°C, followed by the addition of 7 parts of maleic anhydride and 14 parts of 12-aminododecanoic acid. The reaction was carried out at 160°C for 1 hour under nitrogen.

[0475] The reaction was continued for another 20 hours at 200°C to obtain acid-modified polypropylene (a1-1②).

[0476](a1-1②) has an acid value of 32.1 and a Mn value of 2,800.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com