Semi-submergence type sewagte biological contacting oxidation prool and sewage treatment method

A sewage treatment method and a technology of contact oxidation ponds, which are applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problem of ineffective removal of volatile odor-causing organic pollutants, air pollution issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

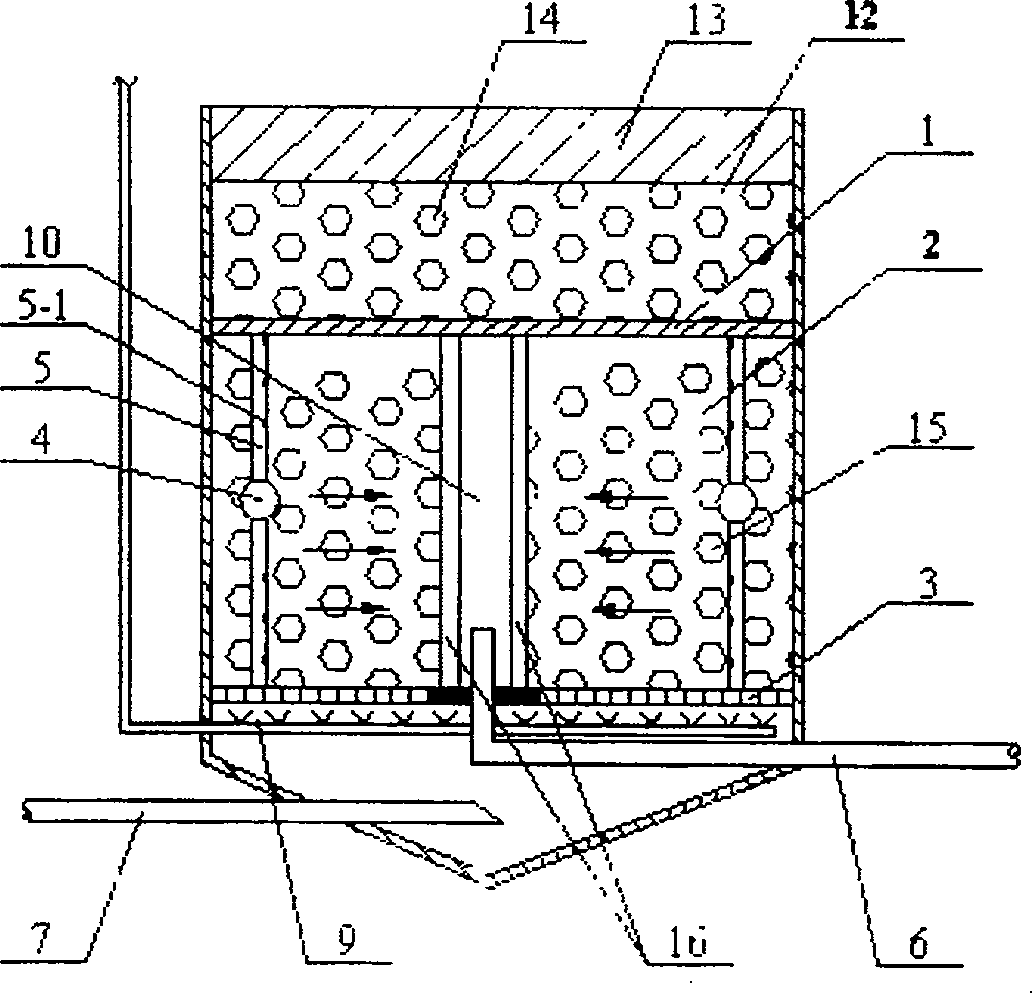

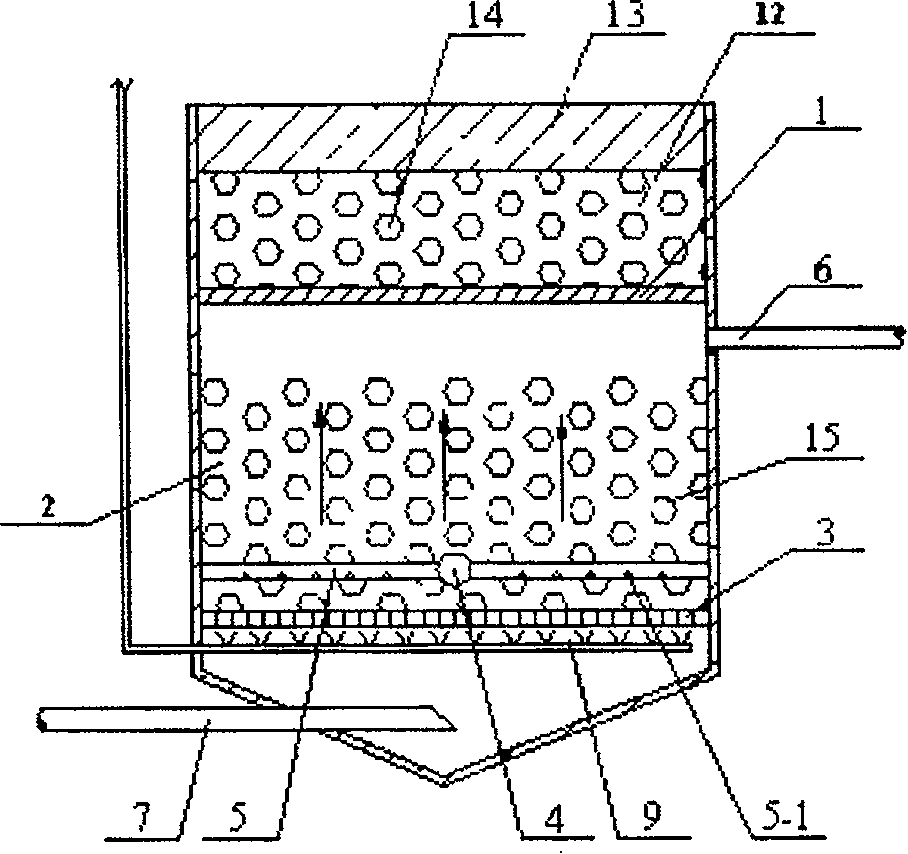

[0005] Specific implementation mode one: combine figure 1 Describe this embodiment, the semi-submerged sewage biological contact oxidation tank of this embodiment is divided into upper and lower parts by the non-submerged filler support layer 1, the upper part is the non-submerged filler layer 12, and the surface of the non-submerged filler 14 is attached with the volatile matter emitted by the sewage. Microorganisms cultivated and domesticated by odor-causing organic pollutants. The lower part includes submerged packing layer 2, aeration device 9, sewage water inlet device and treated water outlet device. Microbes cultivated and domesticated by sewage are attached to the surface of submerged packing 15; biological contact oxidation tank sewage The height of the water inlet and outlet devices is lower than the non-submerged packing support layer 1.

[0006] In this embodiment, the non-submerged filler supporting layer 1 and the upper non-submerged filler 14 completely cover th...

specific Embodiment approach 2

[0007] Specific embodiment two: The difference between this embodiment and specific embodiment one is: the non-submerged filler 14 is made of coke, activated carbon, ceramsite, anthracite, crushed stone, gravel, zeolite, perlite, peat, wood chips, shavings, bamboo chips , sand, slag, ceramic rings, plastic balls, crushed shells, textile fibers, and sponges; the thickness of the non-submerged filler is 0.5-1.2m. Others are the same as the first embodiment.

specific Embodiment approach 3

[0008] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the non-submerged filler 14 is composed of coke, activated carbon, ceramsite, anthracite, plastic balls, broken shells, cotton, sponge and textile fibers; the non-submerged filler The thickness is 0.6-1.1m. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com