Processing method for engineering machinery wheel assembly

A processing method and technology of construction machinery, applied in the field of mechanical processing and processing of construction machinery wheel parts, can solve the problems of reduced product strength and reliability, low production efficiency, complicated process, etc., and achieve convenient production and processing, increased production efficiency, and improved process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

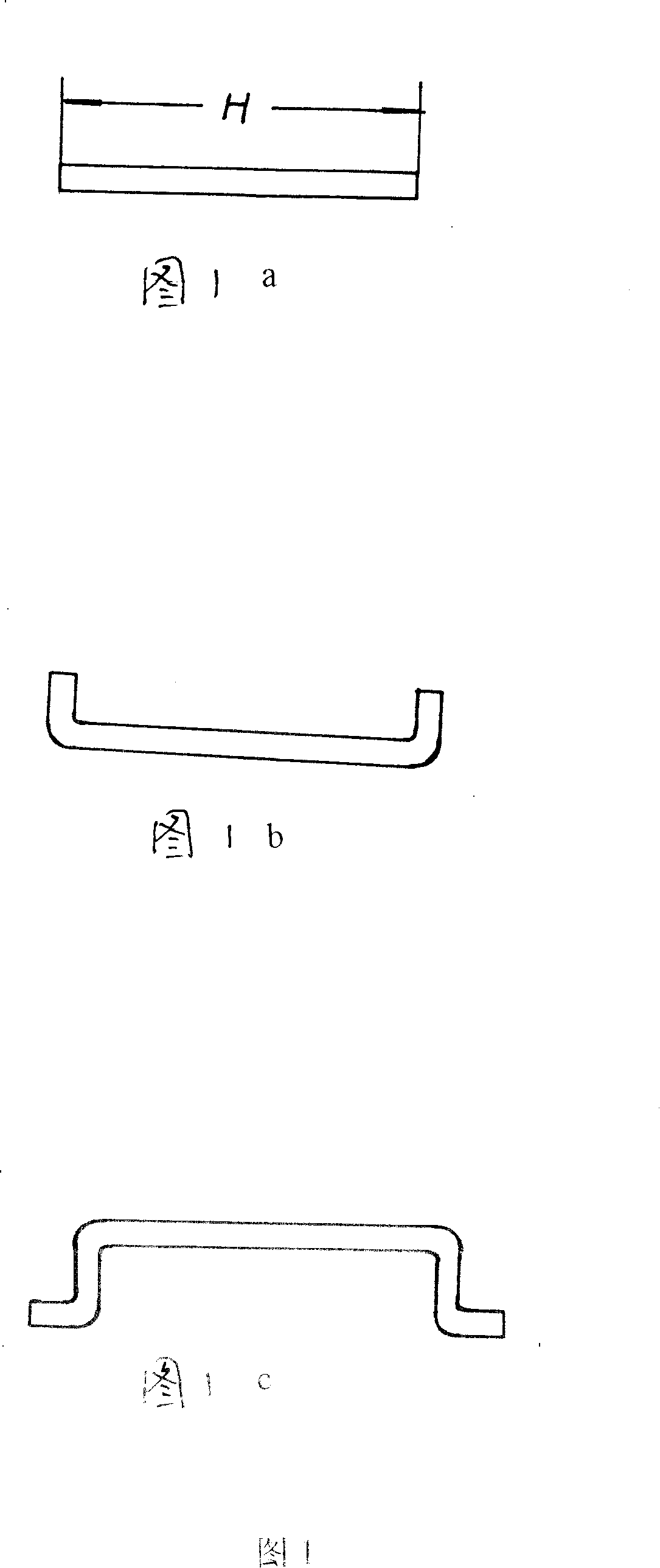

[0011] 1. Cutting: Figure 1a shows the end view of the width direction of the blanking strip, and its width H should be equal to the required width of the two rim parts.

[0012] 2. Bending: Firstly, mechanically stretch the small bend of the rim. As shown in Figure 1b, the two long sides of the material strip shown in Figure 1a are bent upwards according to the required size, so that the material strip is grooved. Secondly, stretch the wheel rim with a large bend. As shown in Figure 1c, the two long sides of the groove-shaped material strip in Figure 1b are bent again, and the material strip is Ω-shaped.

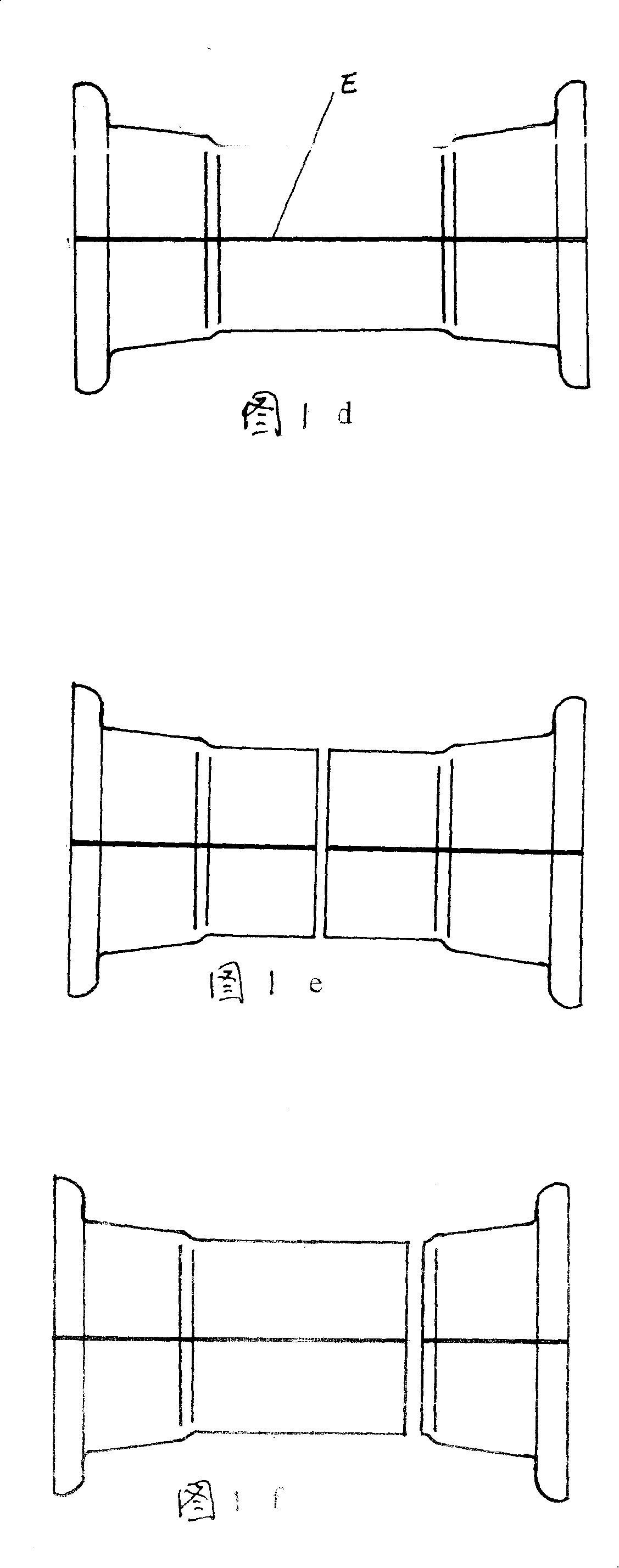

[0013] 3. Then perform rounding, and roll the strip after twice stretching into a cylindrical shape as shown in Figure 1d.

[0014] 4. Butt weld the interface E of the rolled cylinder (as shown in Figure 1d).

[0015] 5. Cutting. The cylinder is cut into two sections at the central position shown in Fig. 1e, which becomes two rim parts, and then respectively welded with th...

Embodiment 2

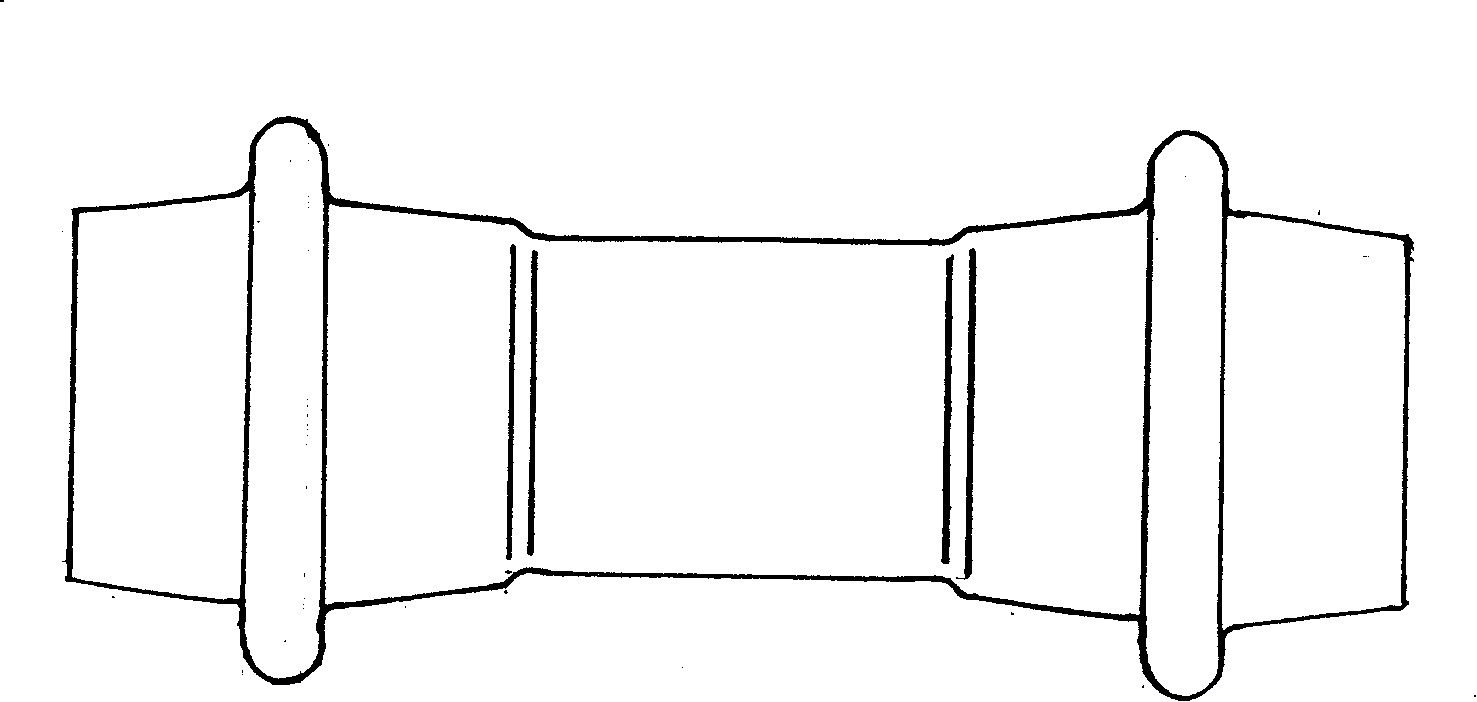

[0016] Embodiment two: if Figure 2a As shown in -b, two rims and two retaining rings are processed at one time, and its processing method is: 1. Cutting, its blanking width should be equal to the width of the two rims and two retaining rings. 2. Rounding. After cutting the material, the strip material is first rolled into a cylinder on the plate rolling machine. 3. Butt weld the interface. 4. Roll the cylinder into the required shape on the corresponding rolling die. Five, in Figure 2b The profile is cut in the position shown into four wheel components, two rims and two retaining rings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com