Simulated test platform system for mechanical structure vibration resistant performance

A test platform and mechanics technology, applied in the field of simulation test platform system, can solve the problems of taking a long time, the convenience of performance and adjustment are not satisfactory, and the linear performance is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

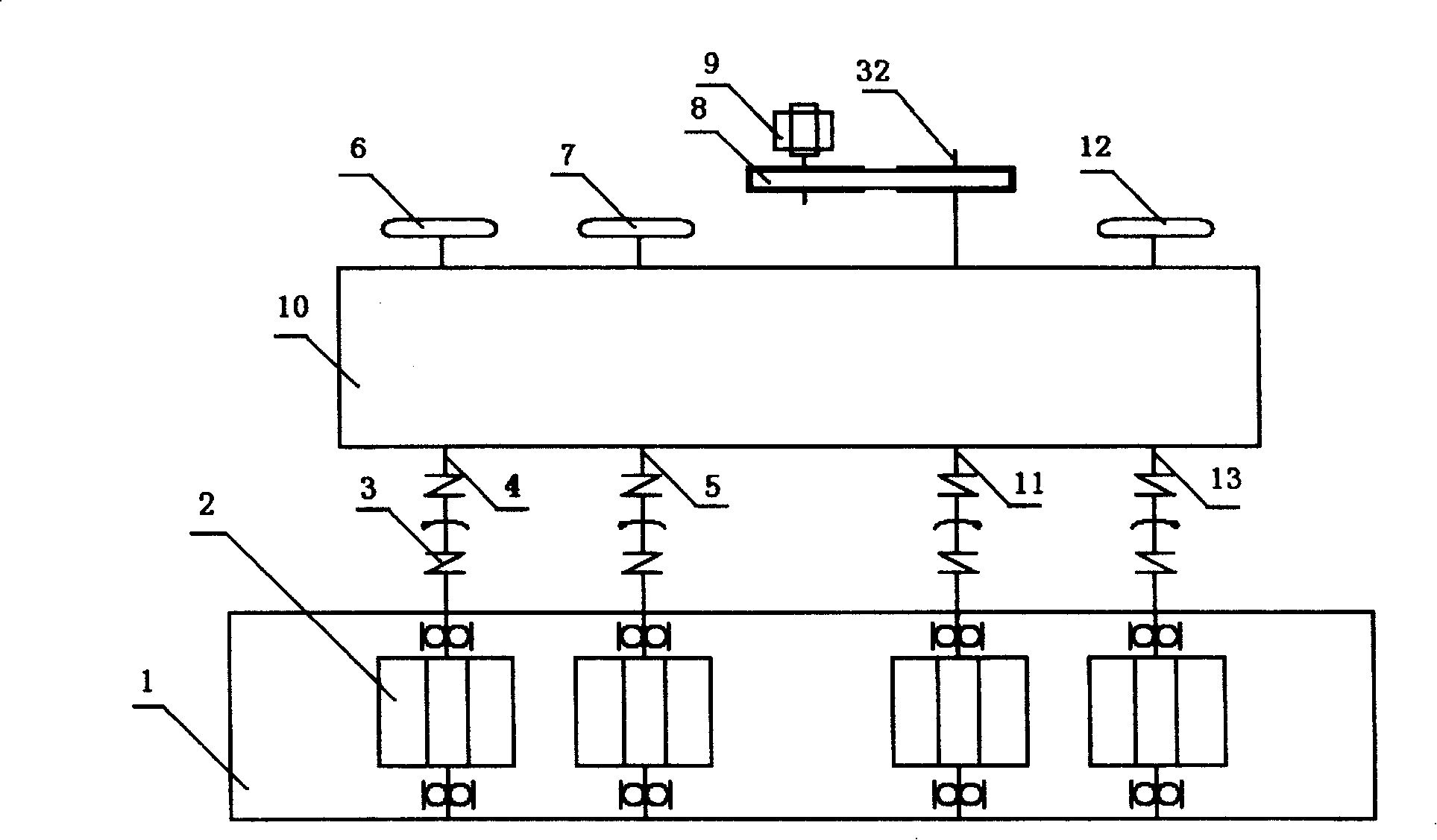

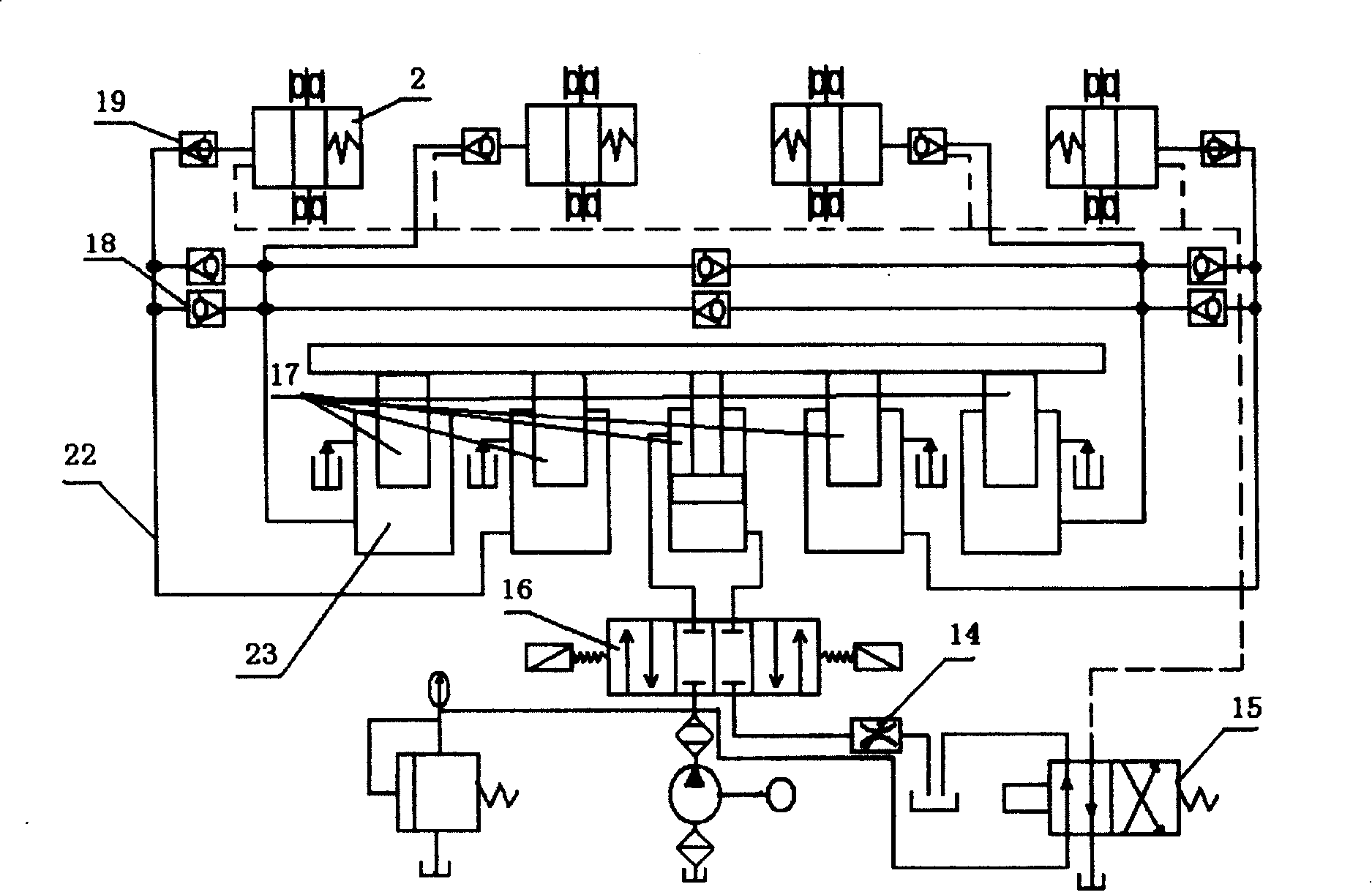

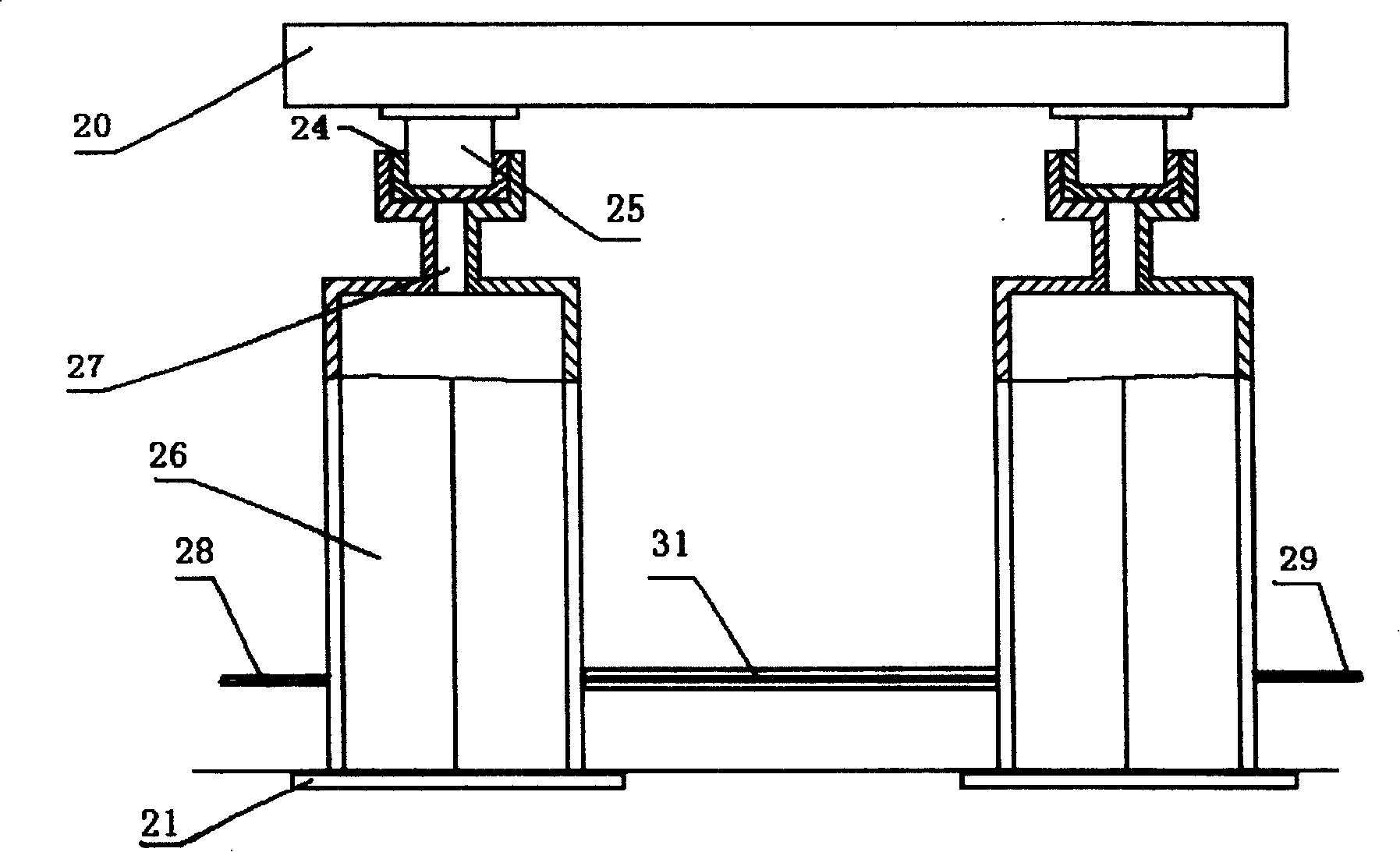

[0013] Such as figure 1 As shown, the four rotary cylinders 2 are connected to the transmission device through four flexible couplings 3; the shaft one 4 and the hand wheel one 6, the shaft two 5 and the hand wheel two 7, the shaft two connected on the flexible coupling 3 Four 13 and hand wheel three, shaft four 13 and drive shaft 32 are connected through gearbox 10; adjusting hand wheel one, hand wheel two, and hand wheel three can set the initial phases of four rotary cylinders 2, when the motor 9 passes through the V-belt 8. When the driving shaft 32 is driven, the eccentric mass of the rotary cylinder 2 rotates to generate a centrifugal force. At this time, the vibration direction is synthesized according to the set phase to form a sinusoidally changing exciting force, so that the table 20 and the test product installed on the table 20 press Vibration is generated in a certain direction. Setting the phase can make the vibrating direction of the table top 20 vibrate in ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com