Method of reducing ammonia and nitrogen pollution in process of zeolite modification

A zeolite and modification technology, which is applied in the field of reducing ammonia nitrogen pollution in the process of zeolite modification, and achieves the effects of reducing the usage of ammonium salt, lowering the sodium content and reducing the ammonium salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

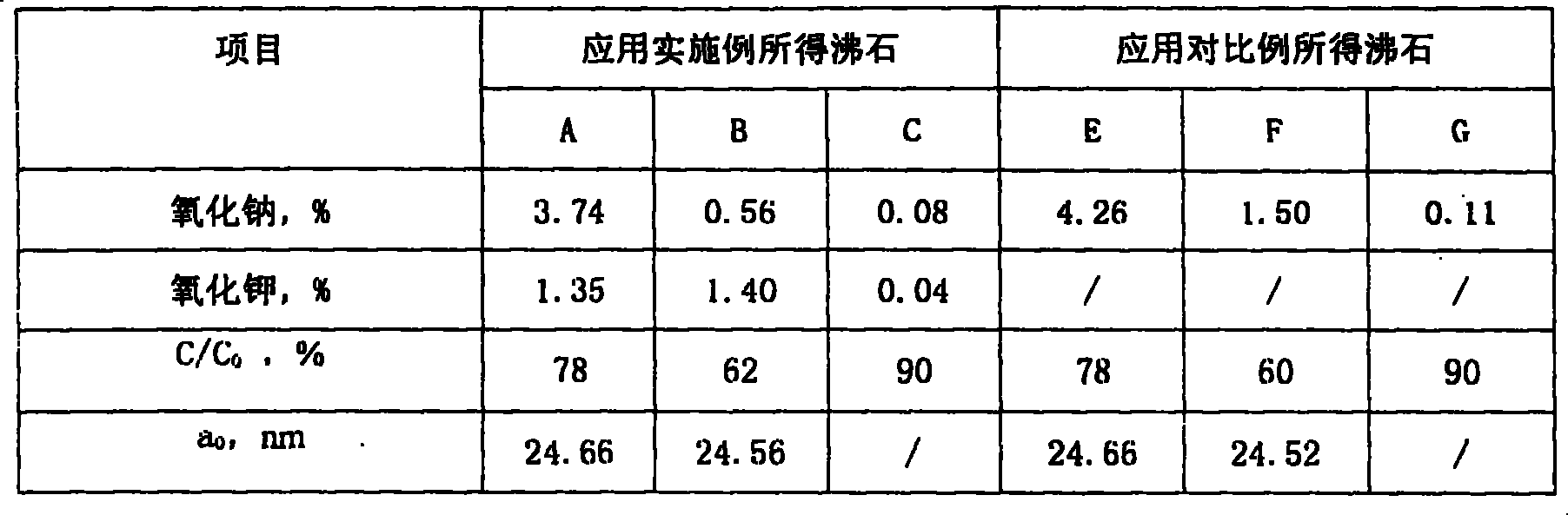

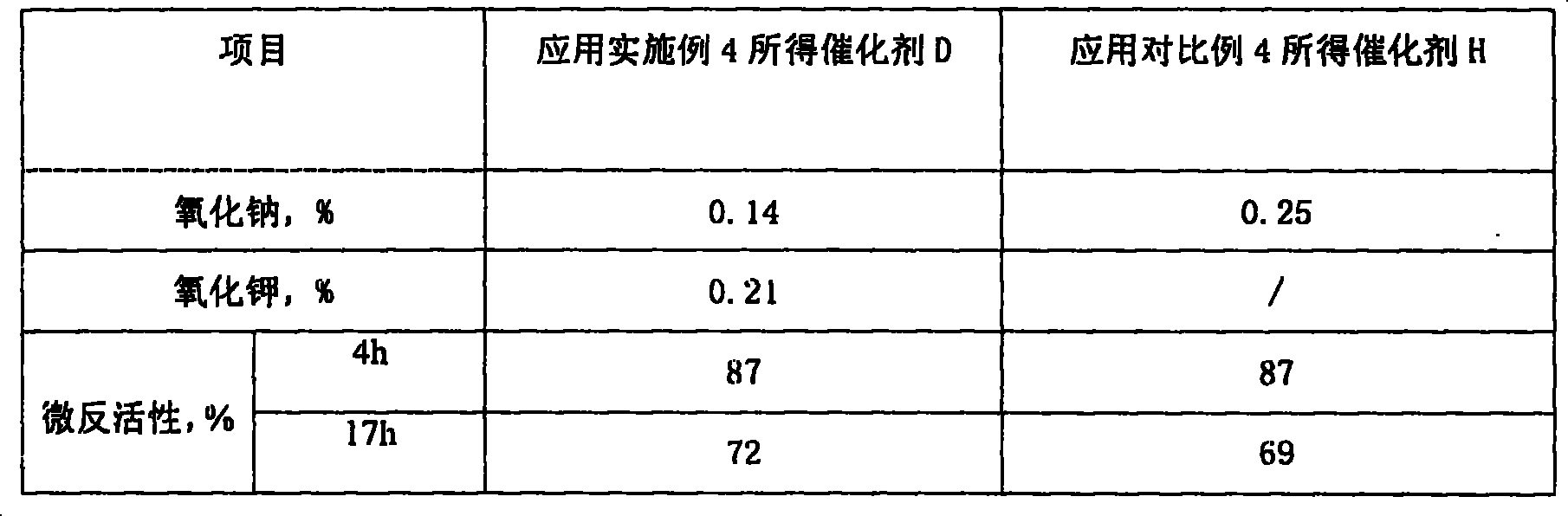

Examples

Embodiment 1

[0030] Under stirring, add 50g (dry basis) NaY to 400ml of water, add 10g of potassium chloride, 6ml of rare earth chloride, add 30ml of hydrochloric acid with a concentration of 18%, heat up to 85°C, keep warm for 1 hour, filter to form filter cake A , the thickness of the filter cake is about 5mm; add 15g of ammonium chloride to 250ml of water to form a solution, raise the temperature to 85°C, add it to the filter cake A, filter, and keep the filter vacuum at 0.06MPa to form the filter cake B. In a muffle furnace, the filter cake was calcined at a temperature of 600° C. for 1.5 h to obtain the zeolite A of the present invention.

Embodiment 2

[0032]Under stirring, add 50g (dry basis) of rare earth super stable Y to 400ml of water, add 5g of potassium carbonate, 2g of ammonium sulfate, add 10ml of 3M sulfuric acid, heat up to 85°C, keep warm for 0.5 hours, filter to form filter cake C, filter cake The thickness is about 5mm; add 10g of ammonium sulfate into 250ml of water to form a solution, raise the temperature to 60°C, add it to the filter cake C, filter, and keep the filter vacuum at 0.06MPa to form the filter cake D. In a muffle furnace, the filter cake was calcined at a temperature of 650° C. for 2 hours to obtain zeolite B of the present invention.

Embodiment 3

[0034] Under stirring, add 400ml of water to 50g (dry basis) Na / ZSM-5, add 3g of potassium nitrate, add 25ml of hydrochloric acid with a concentration of 18%, stir for 4 hours at a temperature of 15°C, filter to form filter cake E, filter The thickness of the cake is about 5mm; add 8g of ammonium nitrate to 250ml of water to form a solution, add it to the filter cake E, filter, and keep the filter vacuum at 0.04MPa to form the filter cake F. In a muffle furnace, the filter cake was calcined at a temperature of 700° C. for 1.5 h to obtain zeolite C of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com