Method and device for removal of thin-film

A thin-film and radiation-oriented technology, which is applied in lasers, laser welding equipment, electrical components, etc., can solve the problem of expensive energy conversion efficiency of femtosecond laser oscillators and achieve the best results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

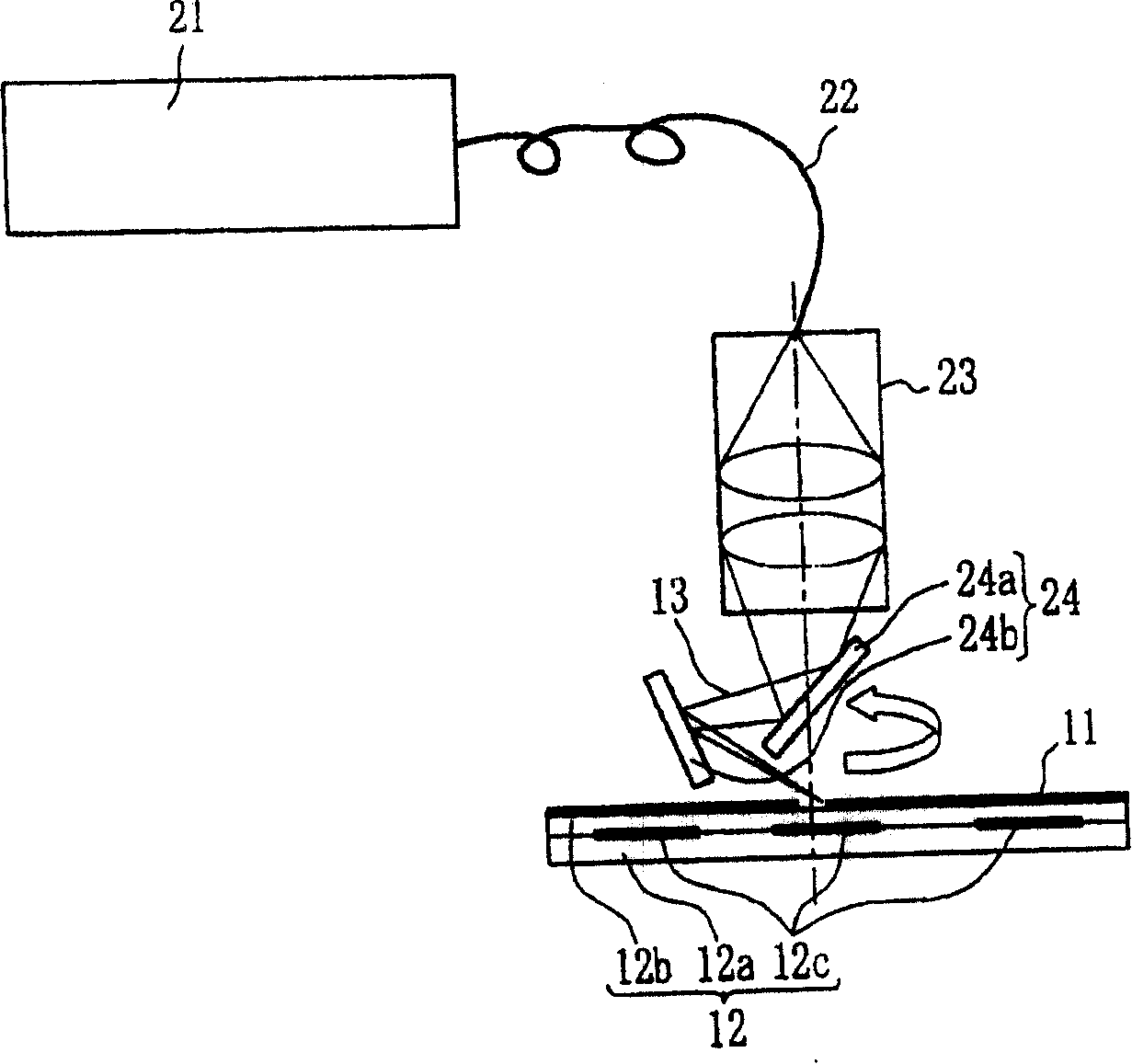

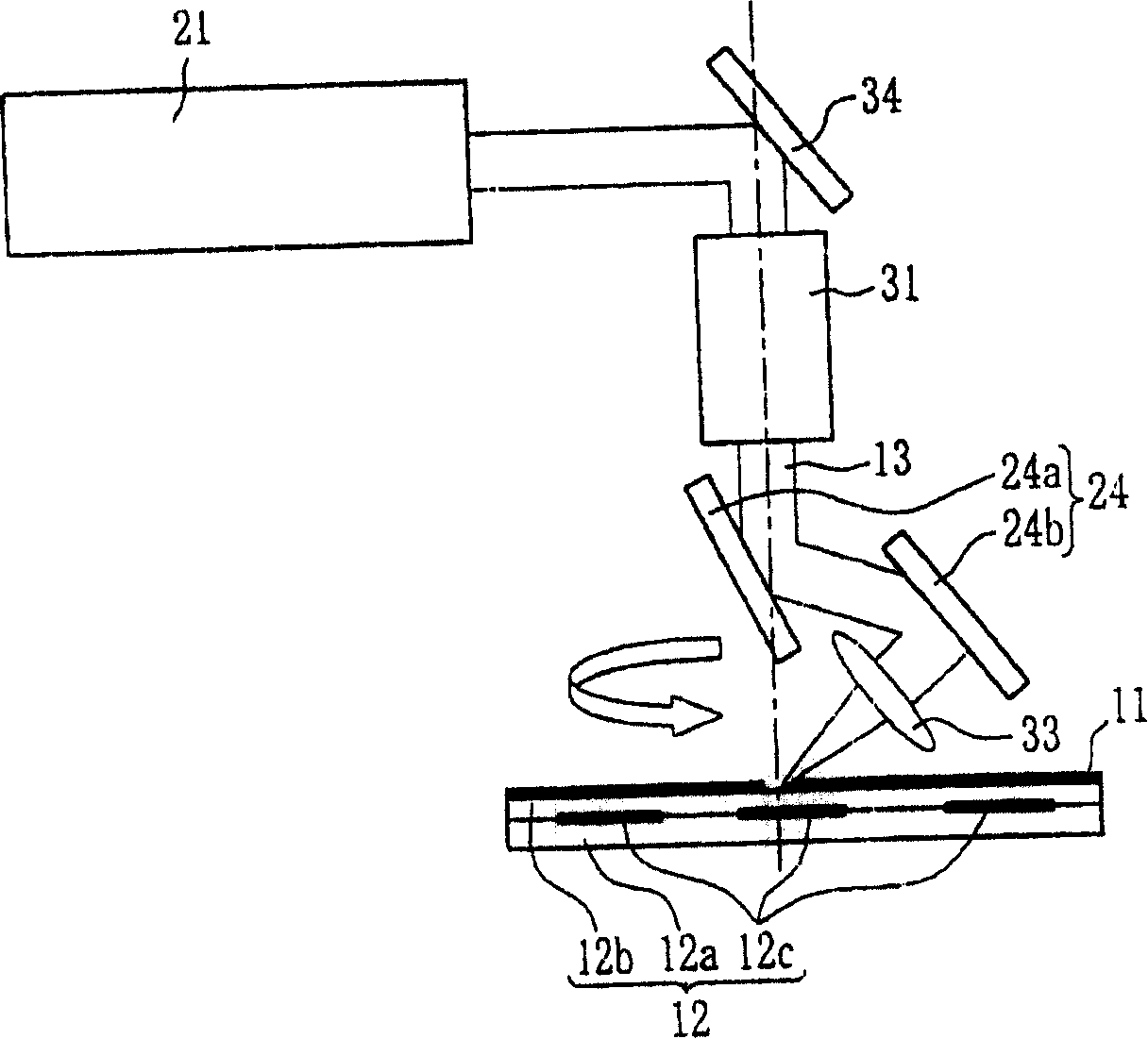

[0049] In order to illustrate the present invention in more detail, the accompanying figure 1 to 5.

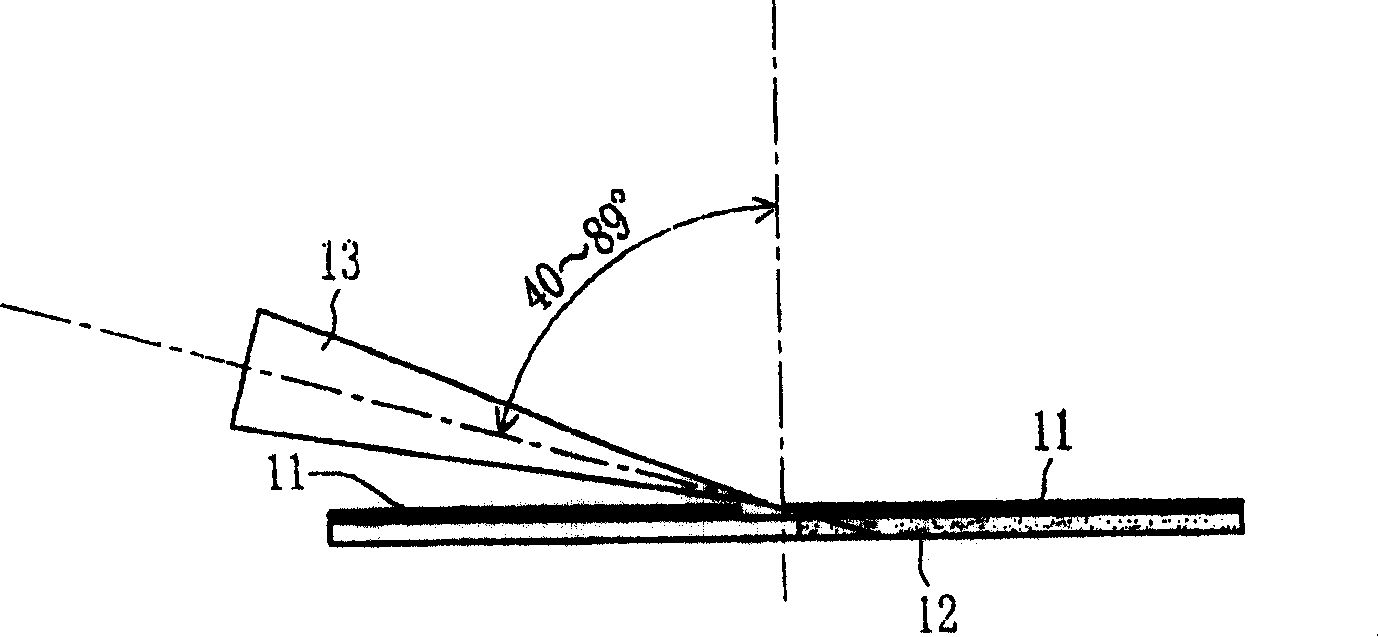

[0050] figure 1 is a schematic diagram illustrating a thin film removal method according to the present invention, such as figure 1 As shown, in the present invention, the top-hat energy distribution is generated by optical fiber transmission or an optical system with a uniform laser beam energy distribution function, so that the laser beam 13 with, for example, 1064 nanometers is irradiated on the substrate 12 made of acrylic layer, The thin film 11 that is coated with for example ITO layer or propylene layer, black matrix layer, glass layer etc. on this substrate surface is inclined 70 from the oblique direction relative to the surface of the substrate 12, such as from the vertical direction perpendicular to the surface of the substrate 12. ° direction with repeated irradiation at a frequency of 100 kHz.

[0051] In the thin film removal method according to the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com