Top comb and top comb holder for a textile combing machine, and the combing machine

A combing machine and top combing technology, which is applied in the direction of combing machines, textiles, papermaking, fiber processing, etc., can solve problems such as wear and tear, and achieve the effect of reducing wear and reducing surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

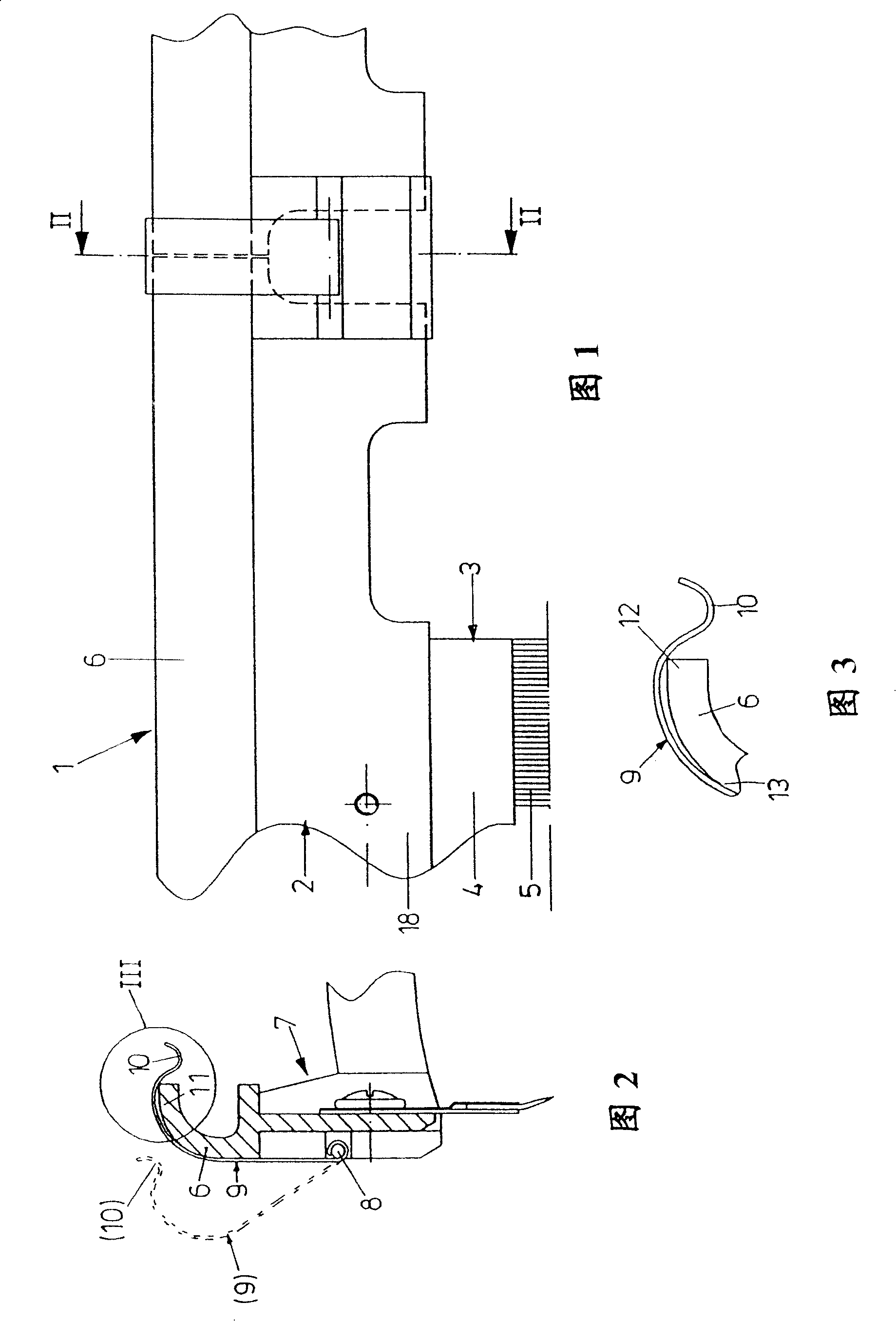

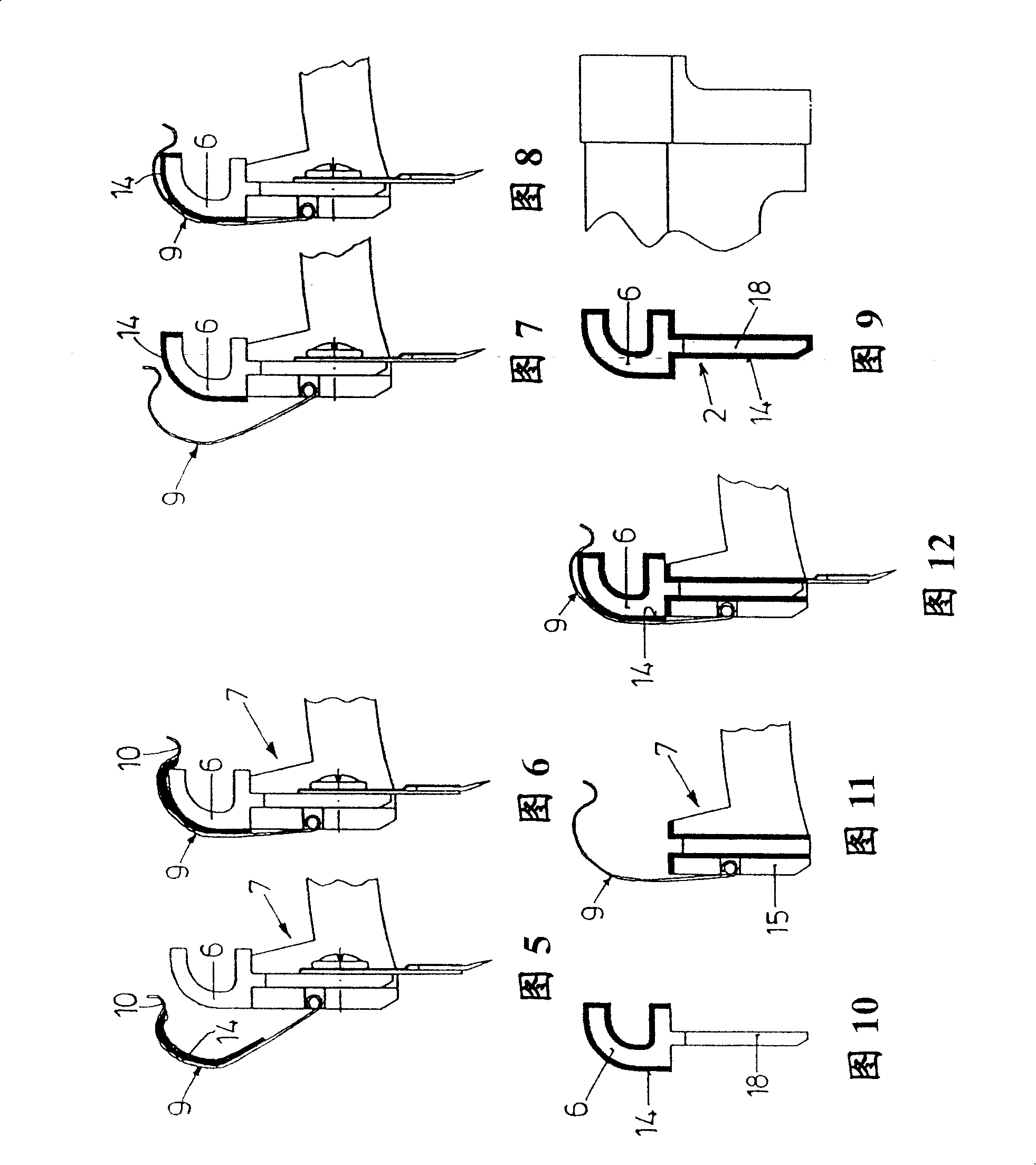

[0030] FIG. 1 shows a top comb 1 according to the prior art, which comprises a top comb plate 2 on which a needle bar 3 with a row of needles 5 clamped between two cover plates 4 is located.

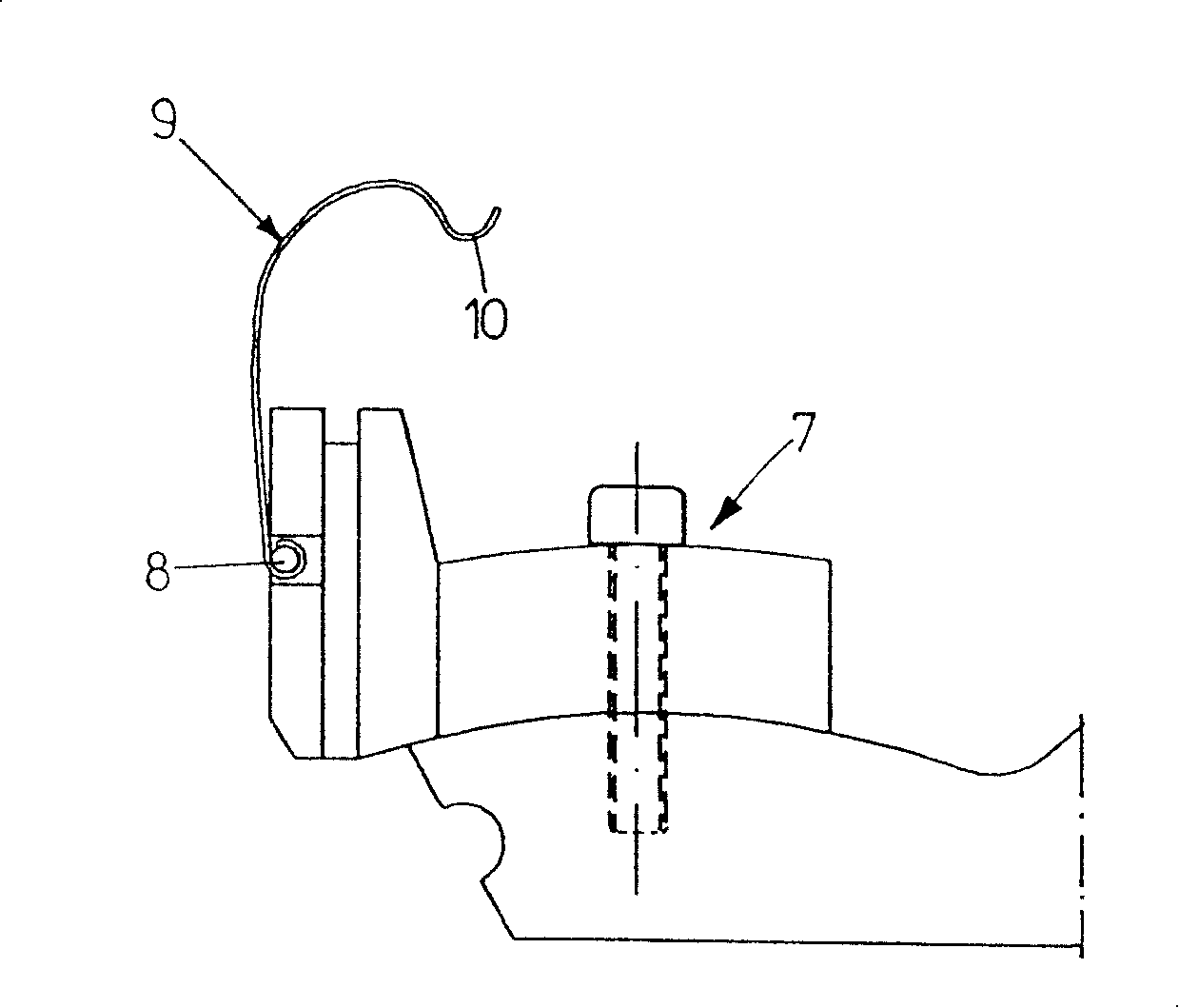

[0031] On the upper side of the top comb plate 2 is formed a fixing section 6 with a surface curved into approximately 1 / 4 of a circle. When the top comb 1 is loaded into the top comb bracket 7 on one side of the comber, the fixed section 6 is pressed by a fixed clamp 9 that can be rotatably supported around the shaft 8, wherein an elbow 10 on the end of the fixed clamp 9 is engaged. Tightly on the inner edge 11 of the fixed section 6. This is shown in more detail in section III in FIGS. 2 and 3 .

[0032] It can also be seen from this that although the shape of the fastening section 6 is precisely given in relation to production, it differs from the shape of the fastening clip 9, so that the fastening clip fits point-like or linearly on the fastening section at points 12 and 13. 6, la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com