Solid organometallic compound-filled container and filling method thereof

An organometallic and compound technology, applied in chemical instruments and methods, solid materials, metal material coating processes, etc., can solve the problem of increased residual volume, difficulty in maintaining the contact state of carrier gas and solid organometallic compounds uniformly, and ineffective use Solid organometallic compounds etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

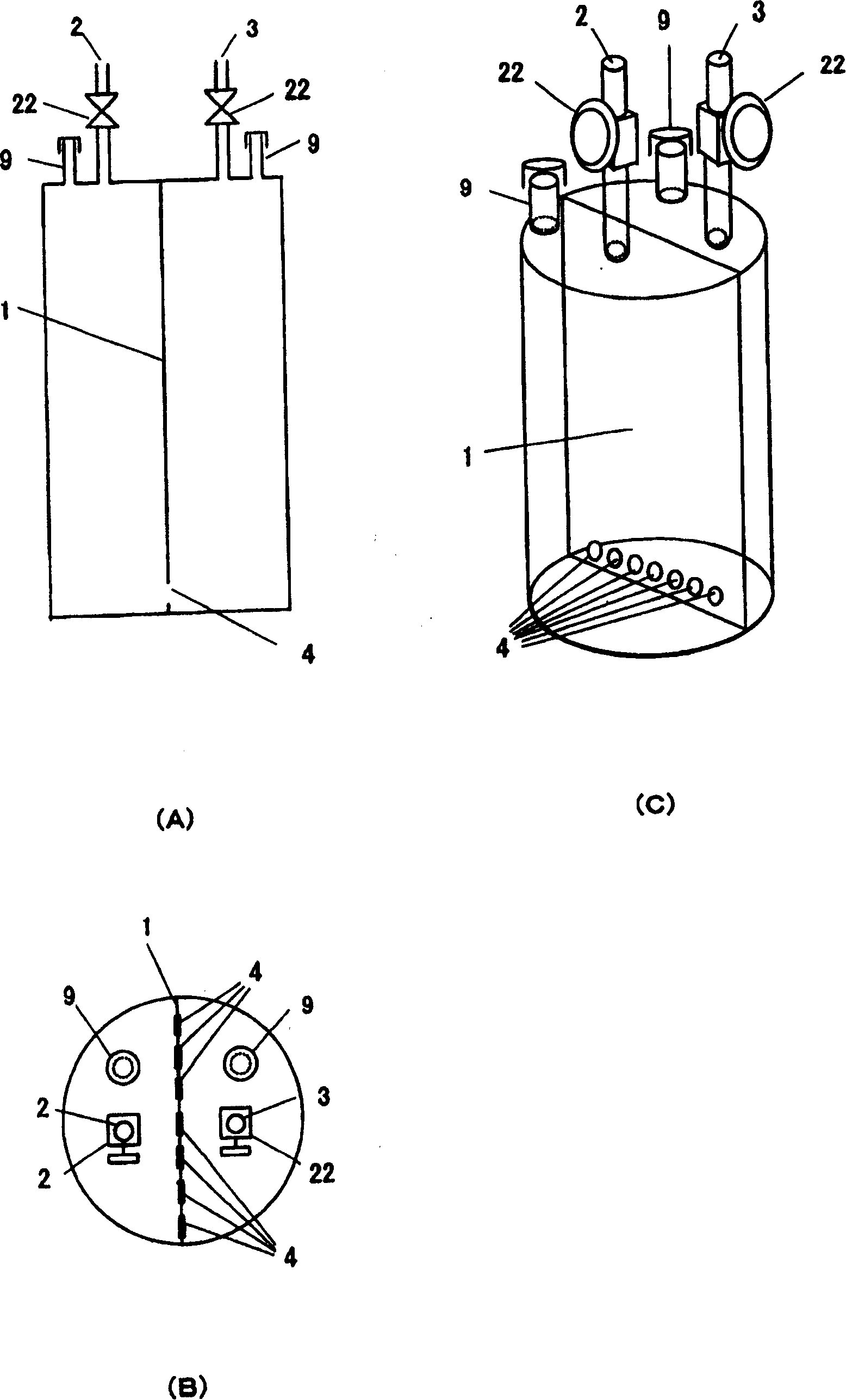

[0079] exist Figure 7 The shown filling container used trimethylindium as the solid organometallic compound, and the supply stability of the solid organometallic compound was tested.

[0080] The test of supply stability was carried out by the following method.

[0081] Fill 400g of trimethylindium and 647g of stainless steel filling material from filling port 9 to Figure 7 This is shown in a filling container made of SUS with an outer diameter φ of 76 mm.

[0082] Subsequently, the carrier gas outlet 3 was connected to a collector cooled with dry ice methanol for the collection of trimethylindium. The piping connecting the carrier gas discharge port 3 and the collector cooled with dry ice methanol was heated so that trimethylindium did not precipitate in the piping. Put the filling container filled with trimethylindium and filling material in a constant temperature bath at 25°C, and make nitrogen gas flow from the carrier gas inlet of the filling container under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com