Tobacco Harm Reduction Treatment Solvent and Method for Reducing Ammonia in Cigarette Mainstream Smoke

A cigarette mainstream smoke and tobacco technology, applied in the fields of tobacco, tobacco preparation, tobacco treatment, etc., can solve problems such as tobacco harm reduction treatment technology that has not been seen yet, achieve good promotion and application value, wide types of tobacco, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) After wrapping 100g of shredded tobacco with a fine gauze net, soak it in 1500ml of tobacco harm reduction treatment solvent (mass about 1500g) for 30min at a temperature of 30°C;

[0028] The tobacco damage reduction treatment solvent consists of water, sodium acetate and Tween-20, wherein the concentration of sodium acetate is 10 -3 mol / L, the mass fraction of Tween-20 is 1.0%, and the balance is water;

[0029] (2) Rinse the shredded tobacco after soaking in step (1) twice with deionized water for 15 minutes each time; the mass ratio of deionized water to tobacco is deionized water: shredded tobacco = 15: 1;

[0030] (3) Dry the shredded tobacco after soaking in step (2) in a rotary drum vacuum dryer at a rotation speed of 30r / min, keep the pressure of the dryer at 0.015MPa, and keep the drying temperature at 40°C for 4 hours; after drying The shredded tobacco is balanced at 22°C and relative humidity of 60% until the water content in the shredded tobacco is 11%...

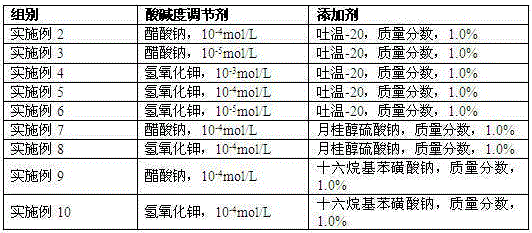

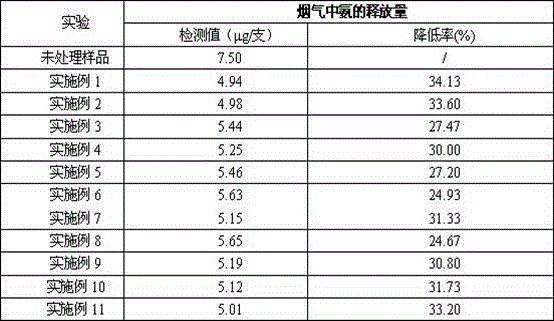

Embodiment 2~10

[0032] The harm reduction treatment process for shredded tobacco in Examples 2-10 is the same as that in Example 1, only the composition of the tobacco harm reduction treatment solvent is adjusted. See the table below for specific adjustments, and see the analysis result comparison table for specific test results.

[0033]

Embodiment 11

[0035] In order to obtain a better tobacco harm reduction treatment effect, the tobacco can also be treated with a tobacco harm reduction treatment solvent, and then continue to be treated with another tobacco harm reduction treatment solvent, for example:

[0036] After wrapping 100g of shredded tobacco with a fine gauze net, soak it in 1500ml of tobacco harm reduction treatment solvent 11-1 (mass about 1500g) for 15 minutes for the first time, and the soaking temperature is 30°C;

[0037] The tobacco damage reduction treatment solvent 11-1 consists of water, potassium hydroxide and Tween-20, wherein the concentration of potassium hydroxide is 10 -4 mol / L, the mass fraction of Tween-20 is 1.0%, and the balance is water;

[0038] The shredded tobacco after soaking is placed again in 1500ml of tobacco harm reduction treatment solvent 11-2 (mass about 1500g) for 15min for the second time, and the soaking temperature is 30°C;

[0039] The tobacco damage reduction treatment solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com