Automatic rolling cutting machine for stamped spool packaging bag

A cutting machine and packaging bag technology, which is applied in the directions of transportation and packaging, coiling strips, and thin material processing, can solve the problems of inability to meet packaging requirements, increased risk, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

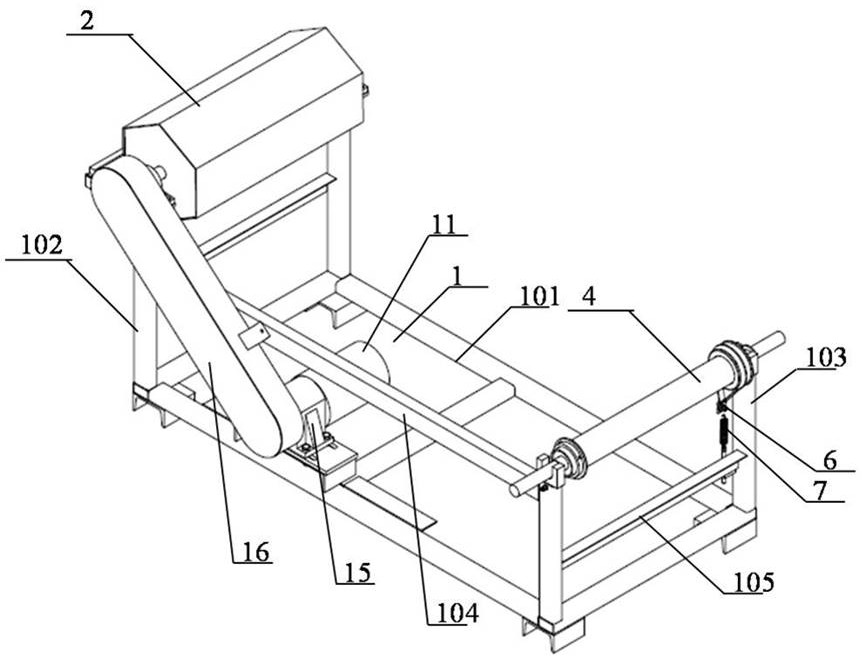

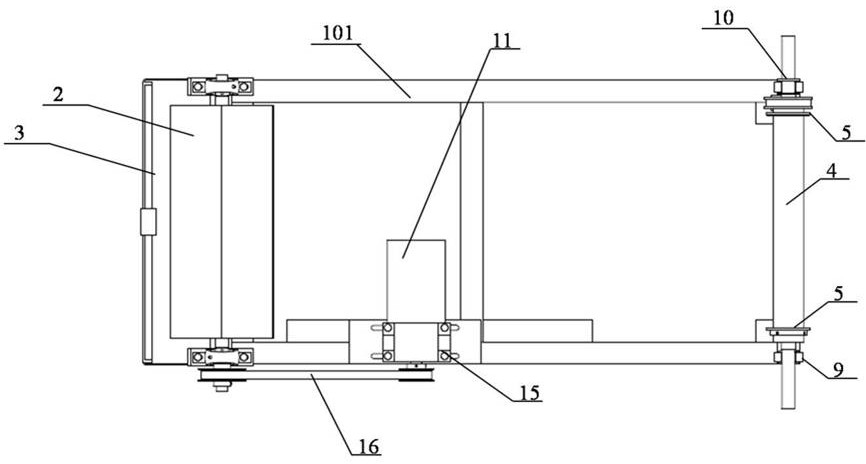

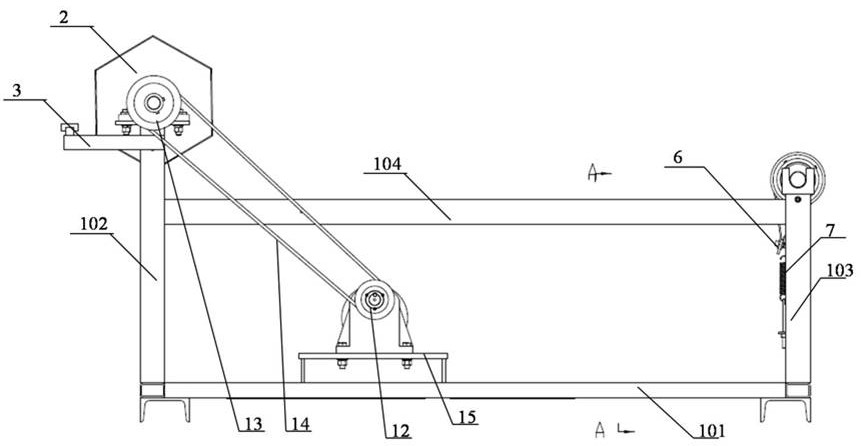

[0030] like Figure 1-Figure 4 Shown is a stamping I-shaped wheel packaging bag automatic winding and cutting machine, the cutting machine includes a bracket 1, and the bracket 1 includes a bottom frame 101, and two left and right sides are fixedly connected to the left and right ends of the bottom frame 101, respectively. Pillar 102 and two right pillars 103, a side support 104 is connected between the left pillar 102 and the right pillar 103 at the front side, and a cross bar 105 is arranged at the bottom between the two said right pillars 103, said The upper end of the left pillar 102 is fixedly connected with a winding reel 2, and the cross section of the rewinding reel 2 is a regular hexagon; It is fixed on the left pillar 102; on the upper end surfaces of the two right pillars 103, a concave support block seat 9 is fixedly connected, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com