Generation system for adjusting fuel injection pressure in hyperpressure for diesel engine

A fuel injection and generation system technology, applied in the direction of fuel injection pumps, fuel injection devices, charging systems, etc., can solve the problems that the quality of parts is limited by material properties and processing accuracy, etc., to achieve extended service life, flexible control and adjustment, The effect of a reasonable system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

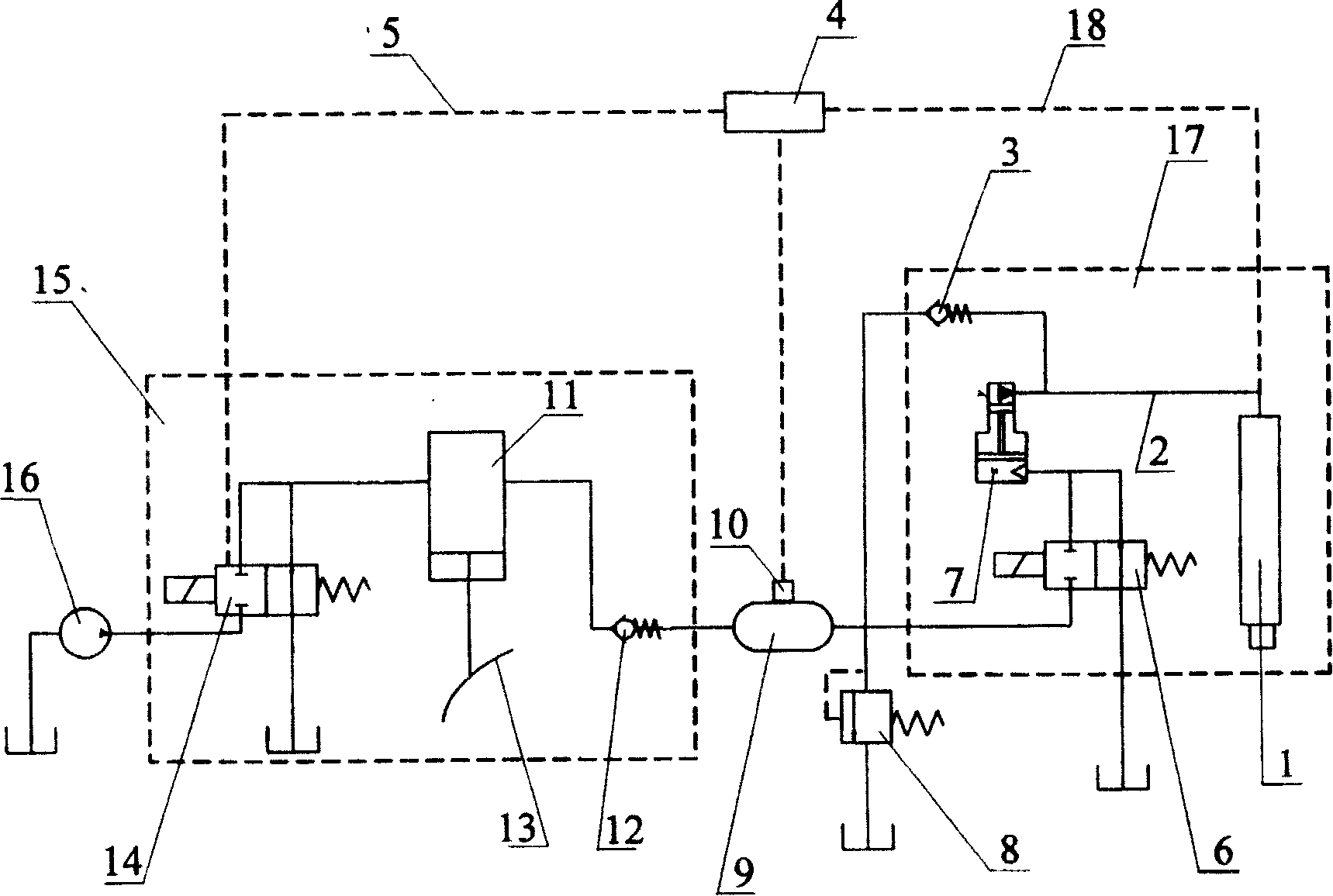

[0017] The accompanying drawing shows the principle diagram of the diesel engine adjustable ultra-high pressure fuel injection pressure generating system of the present invention. It can be seen from the figure that the system includes a pressure closed-loop feedback control circuit 5 composed of a low-pressure oil pump 16, an electronically controlled medium-pressure plunger pump 15, an electronic control unit 4, a pressure accumulator 9, a relief valve 8 and a pressure sensor 10, and a pressure closed-loop feedback control circuit 5 composed of a first An ultra-high pressure fuel injection circuit 17 composed of a check valve 3, the first two-position two-way solenoid valve 6, a supercharger 7, an ultra-high pressure oil pipe 2 and a fuel injector 1; The medium-pressure control plunger pump 15 is composed of a plunger coupling 11 and a second two-po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com