Ribbed plate type heat exchanger with medium equipartition device

A technology for equalizers and heat exchangers, which is applied in the types of heat exchangers, indirect heat exchangers, and heat exchange equipment. The utilization and other issues to achieve the effect of strengthening the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

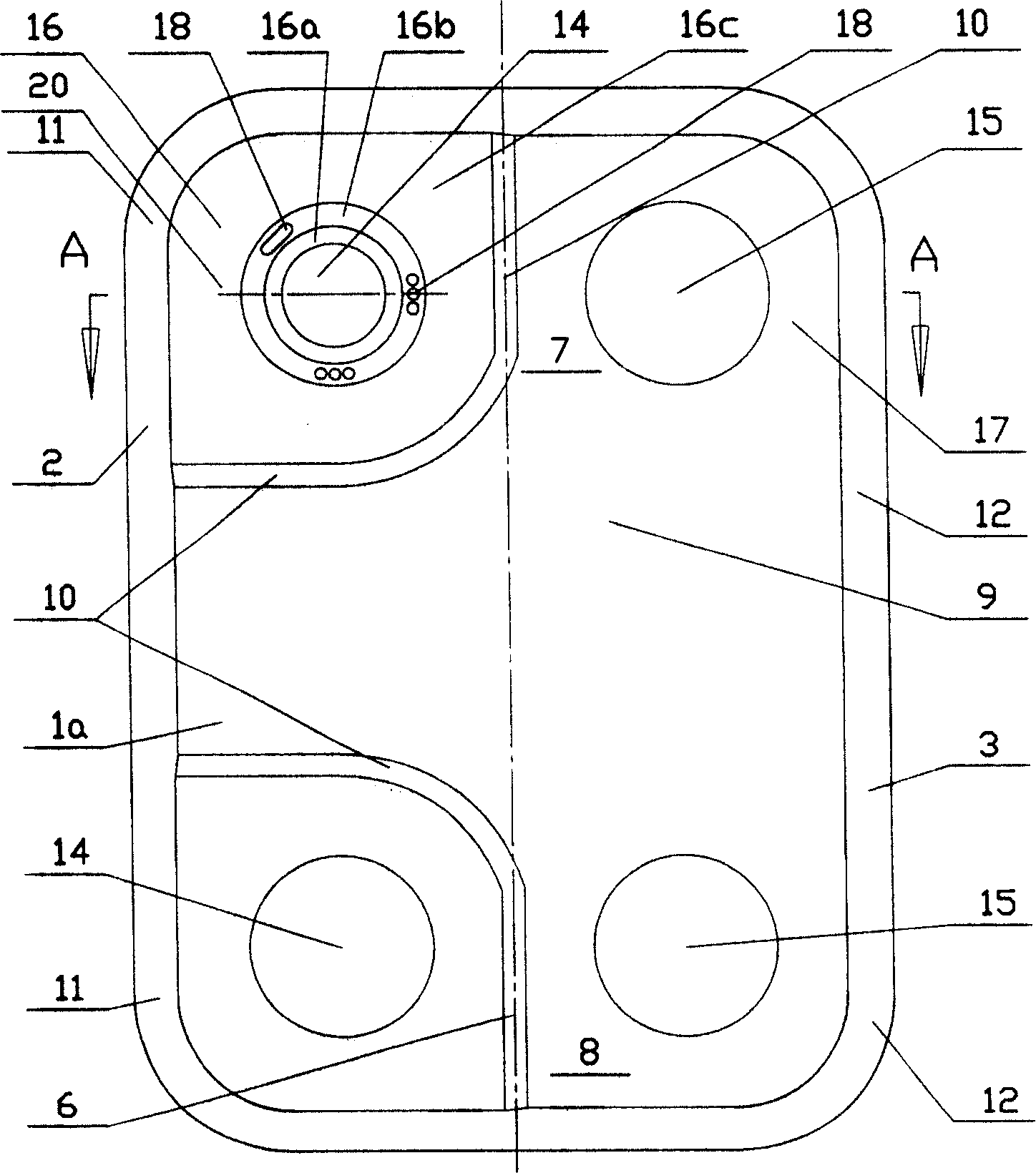

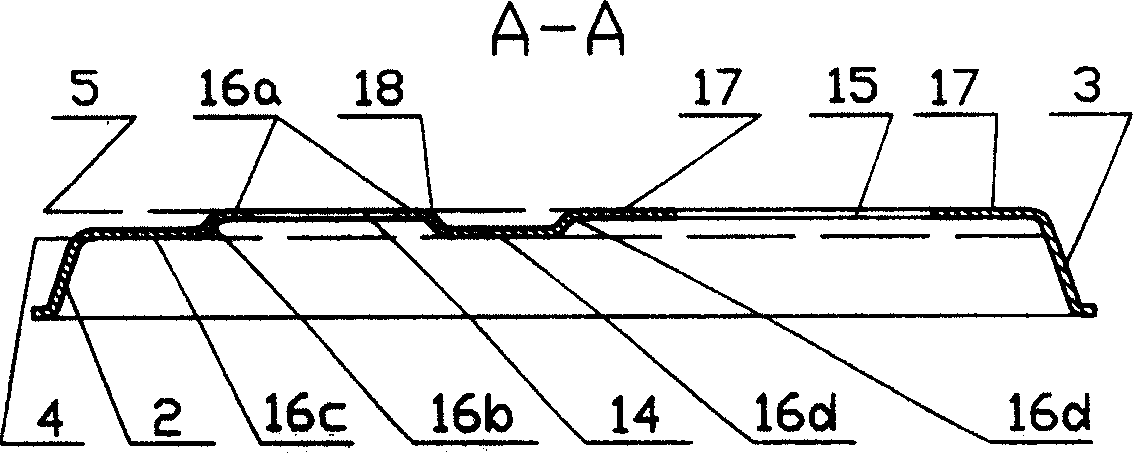

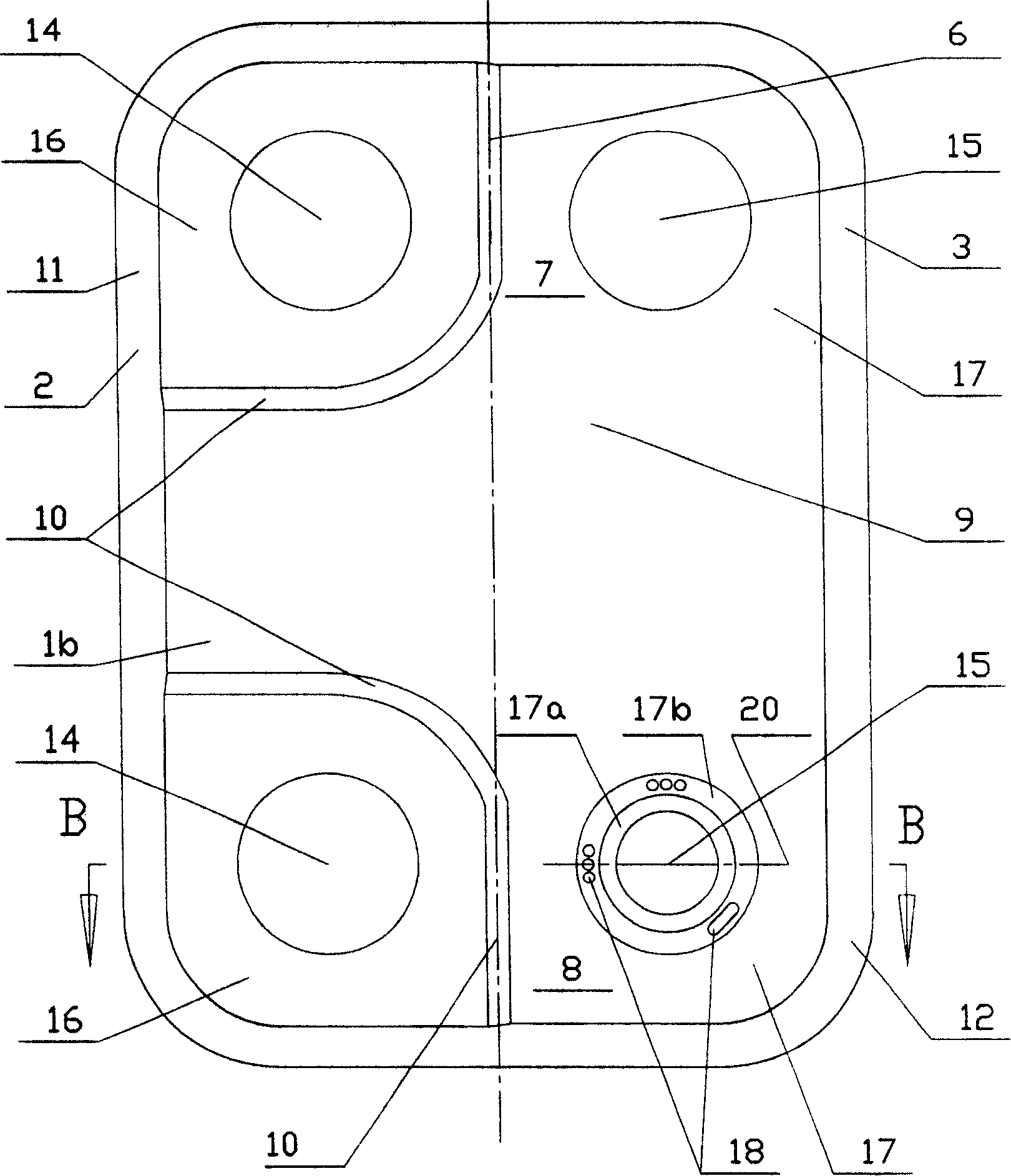

[0032] as attached figure 1 , 3 As shown, a ribbed heat exchanger with a medium divider includes at least two heat exchange plates 1a, 1b, and each heat exchange plate 1a, 1b is in the first edge area 2 and the second edge area 3 There is an extension of the upper plate plane 4 and the lower plate plane 5 parallel to each other, and the center line 6 divides the heat exchange plate 1a, 1b into a first part 11 and a second part 12, wherein each heat exchange plate 1a, 1b includes : a first end region 7; a second end region 8; a central heat transfer region 9 between the first edge region 2 and the second edge region 3 from the first end region 7 to the second end region 8 Extension; the first corner hole 14 and the second corner hole 15, which pass through the heat exchange plates 1a, 1b in the first end region 7 and the second end region 8 to form through holes and are respectively adjacent to the edge region Surrounding, wherein the first corner hole 14 is located in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com