Stepping omnibearing nano moving platform and control system control

A mobile platform and control system technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of wire interference and the inability of the nano mobile platform to achieve plane omnidirectional motion at the same time, and achieve high precision, simple structure, load big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

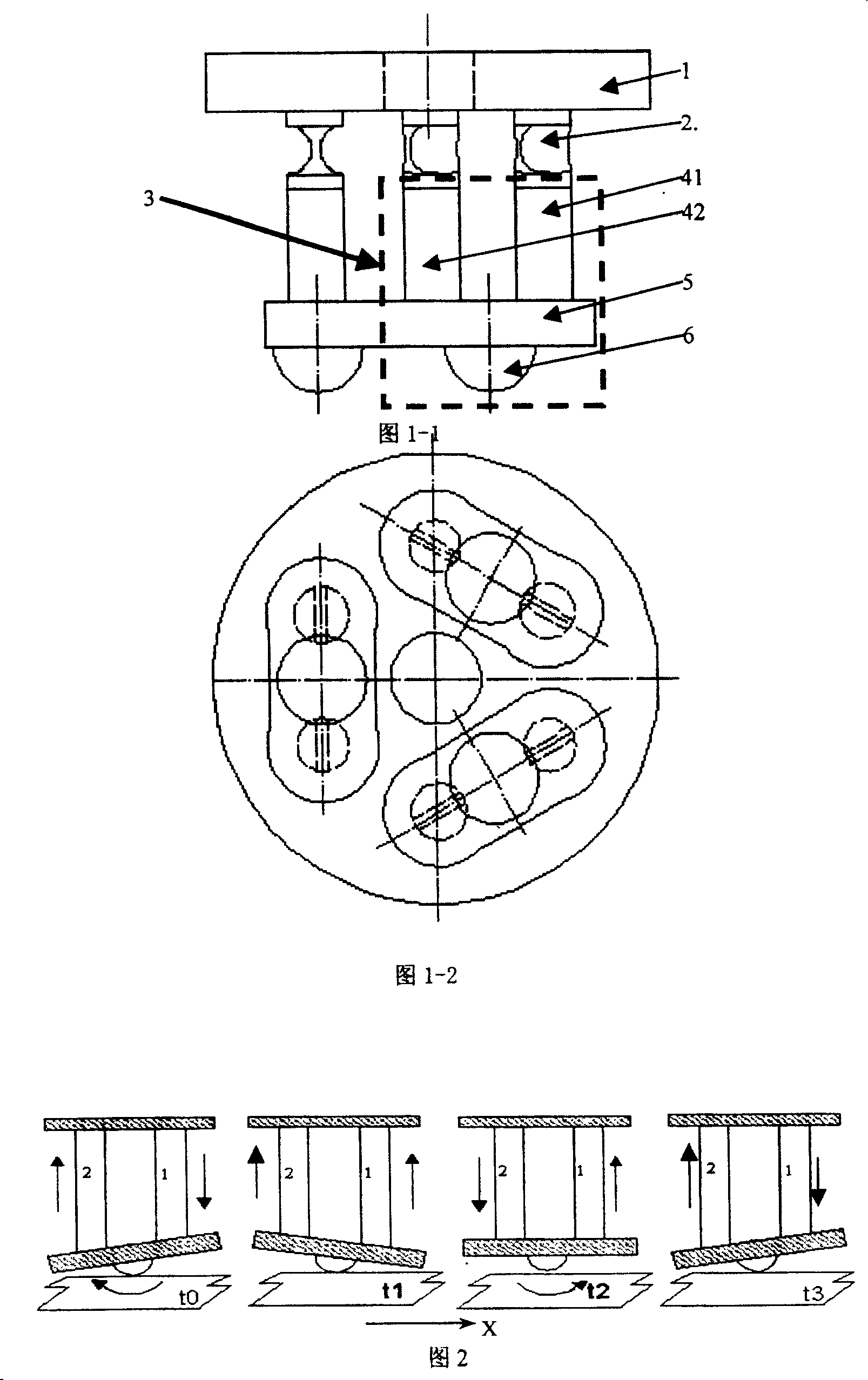

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

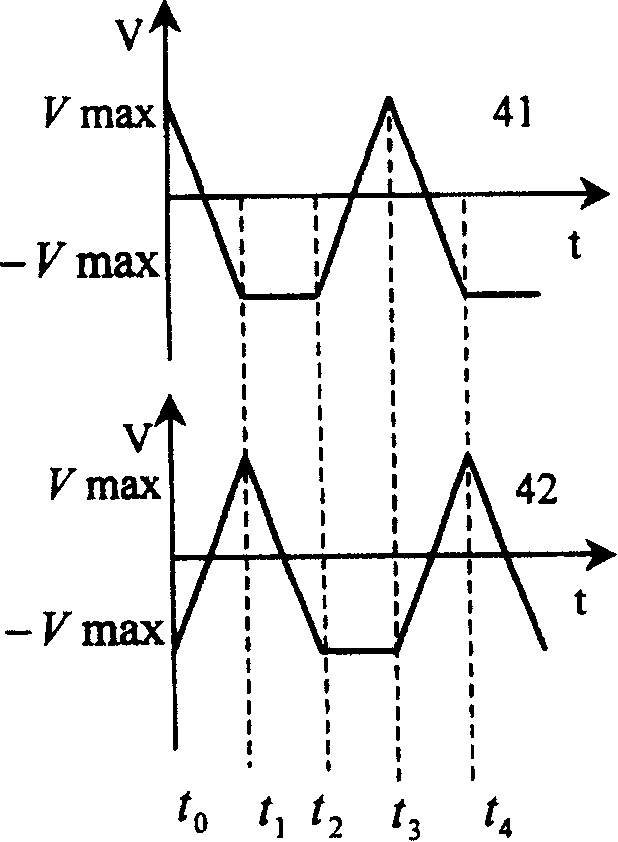

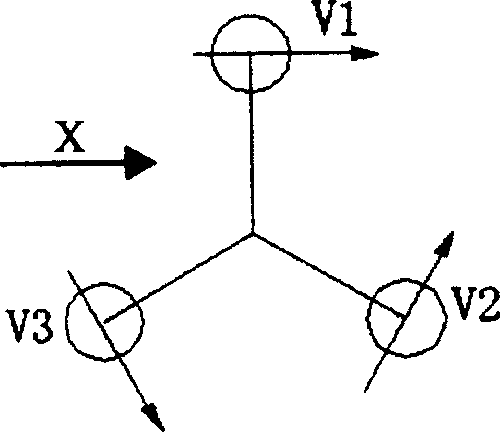

[0025] The nano mobile platform is composed of an upper platform 1 and three groups of piezoelectric drivers. The upper platform 1 and the three groups of piezoelectric drivers are connected by elastic (flexible rotating pair 2) hinges, and the three groups of piezoelectric drivers are symmetrical at 120° along the circumference of the upper platform 1. Arrangement; each group of piezoelectric drivers includes at least one drive unit, and more than two drive units are arranged in series; each drive unit is composed of two piezoelectric ceramics, a beam and a contact element, and the upper ends of the two piezoelectric ceramics are connected to the upper The platform 1 is hinged with elastic (flexible rotating pair 2 ), the lower end is bonded to the crossbeam 5 , and the contact element 6 is bonded to the crossbeam 5 below it.

[0026] Each piezoelectric cera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com